Clutch outer member for multi-plate clutch

A technology for clutches and housings, applied in the field of clutch housings, which can solve the problems of being mistaken for spline grooves, reducing weight and affecting assembly efficiency with bottomed grooves and spline grooves, and achieving the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

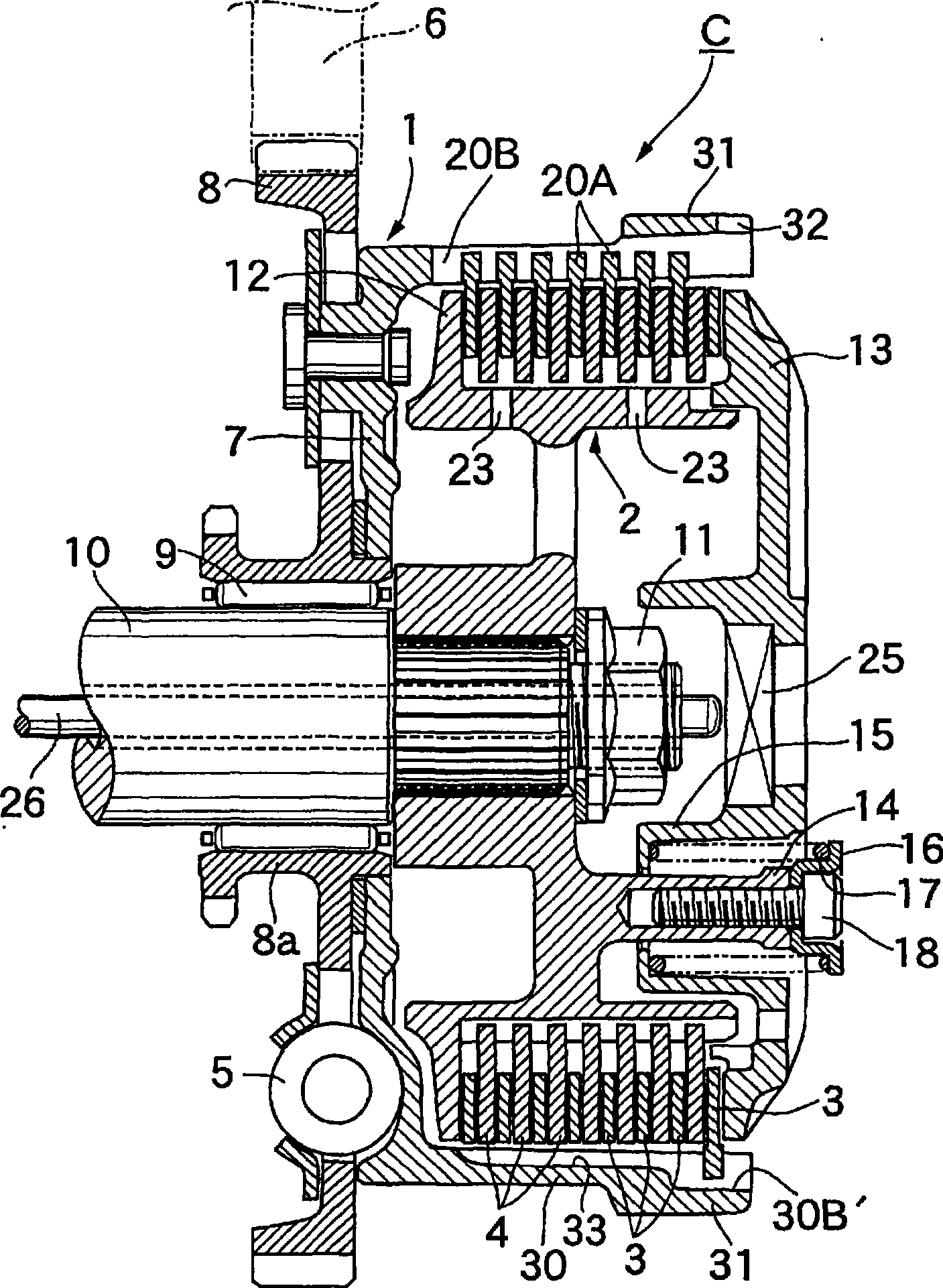

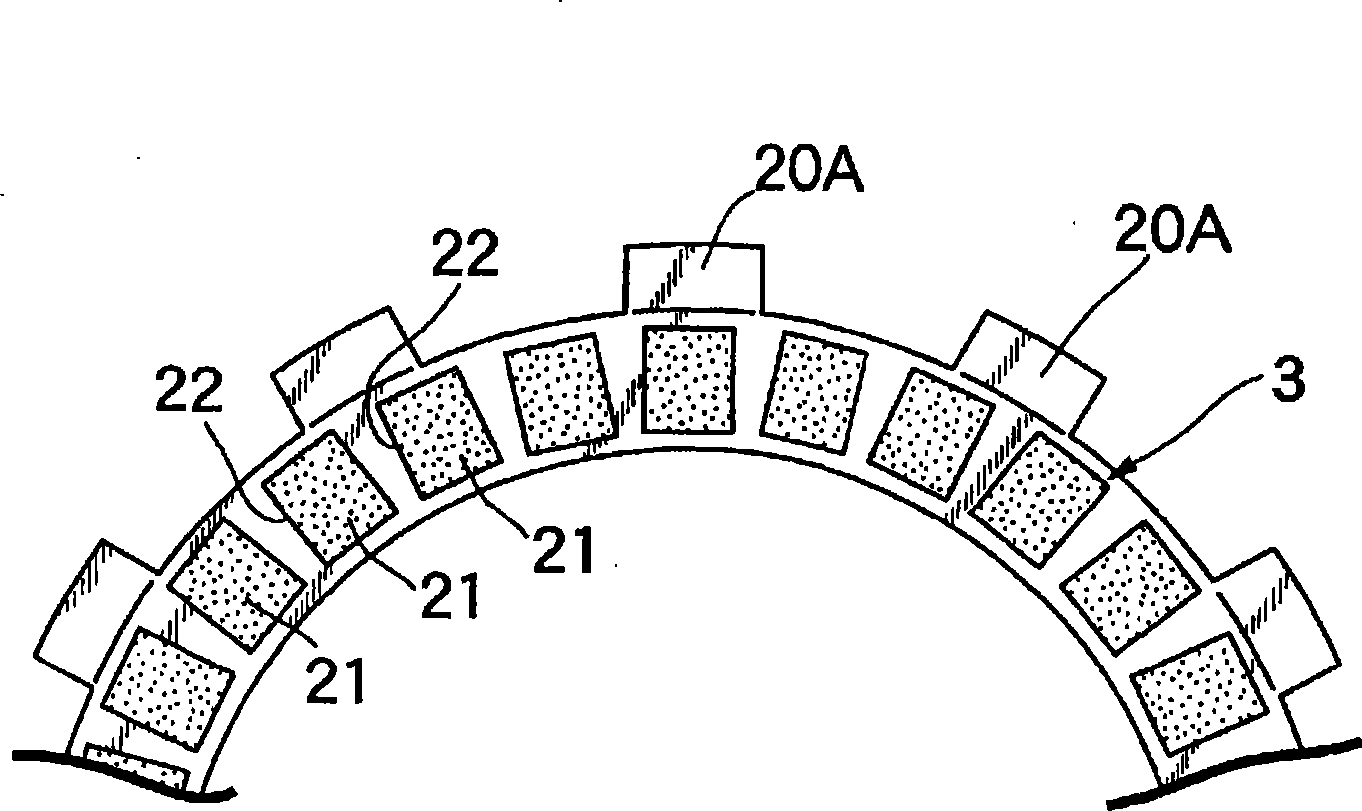

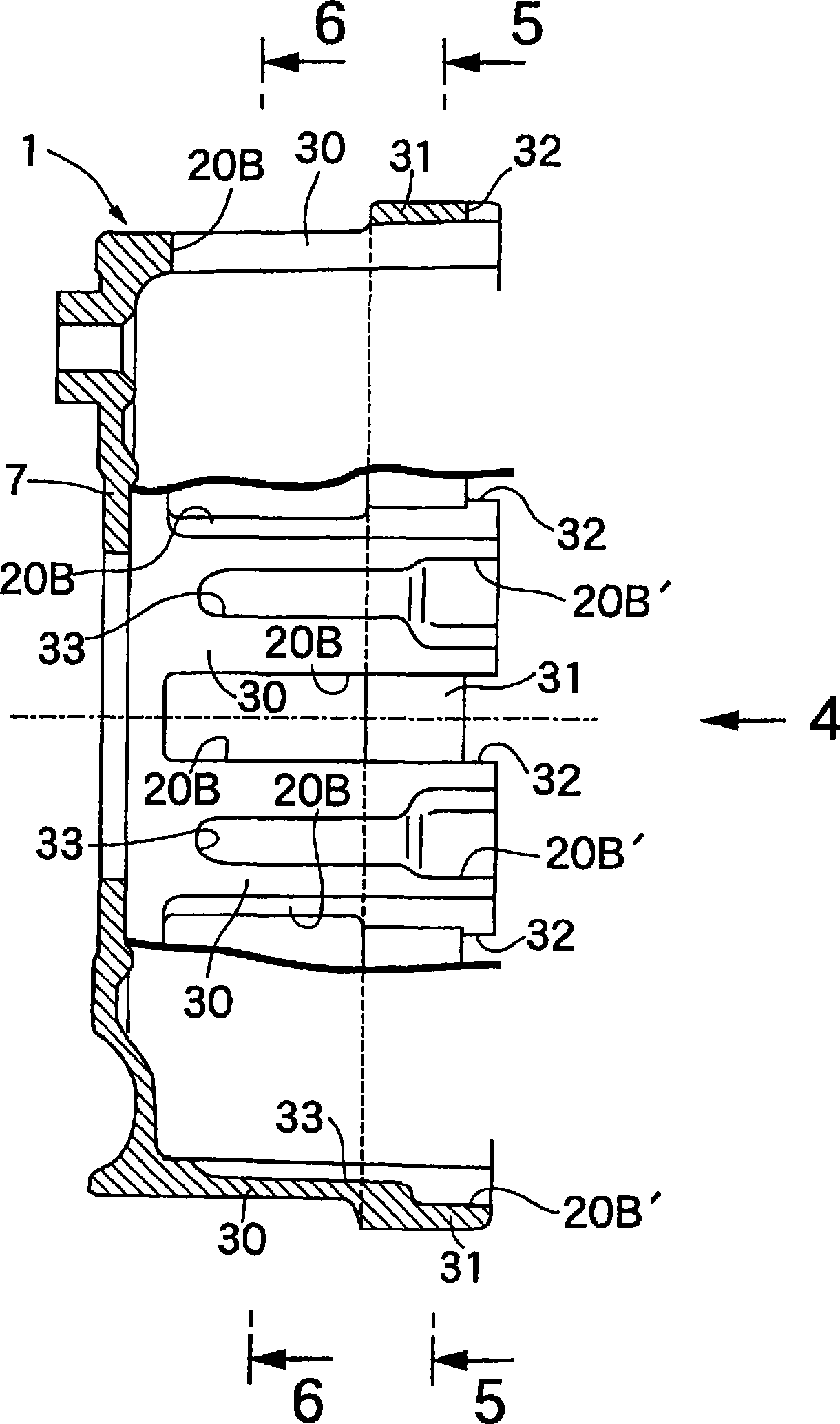

[0029] first, figure 1 The symbol C in is the wet multi-plate clutch of the two-wheeled motor vehicle. This clutch C includes: a clutch housing 1 integrally formed in a bottomed cylindrical shape; a clutch inner housing 2 arranged concentrically in the clutch housing 1; A plurality of driving friction plates 3 around; and a plurality of driven friction plates 4 overlapped with these driving friction plates 3 and are spline-fitted to the outer periphery of the clutch inner housing 2 in an axially slidable manner.

[0030] The input gear 8 meshing with the drive gear 6 of the engine is connected to the end wall 7 of the clutch housing 1 via the torque buffer 5, and the clutch inner housing 2 is connected to the output shaft 10 of the hub 8a supporting the input gear 8 via the needle bearing 9. keyed and secured with nuts 11.

[0031] A pressure receiving plate 12 facing the innermost drive friction plate 3 is integrally formed at the inner end of the clutch inner case 2 . And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com