Arrangement structure of engine valve actuating mechanism

A technology of gas distribution mechanism and layout structure, which is applied in the direction of engine components, machines/engines, valve devices, etc., and can solve the problems of increasing the time and cost of the cylinder head machine, and the angle of the tool cannot be unified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

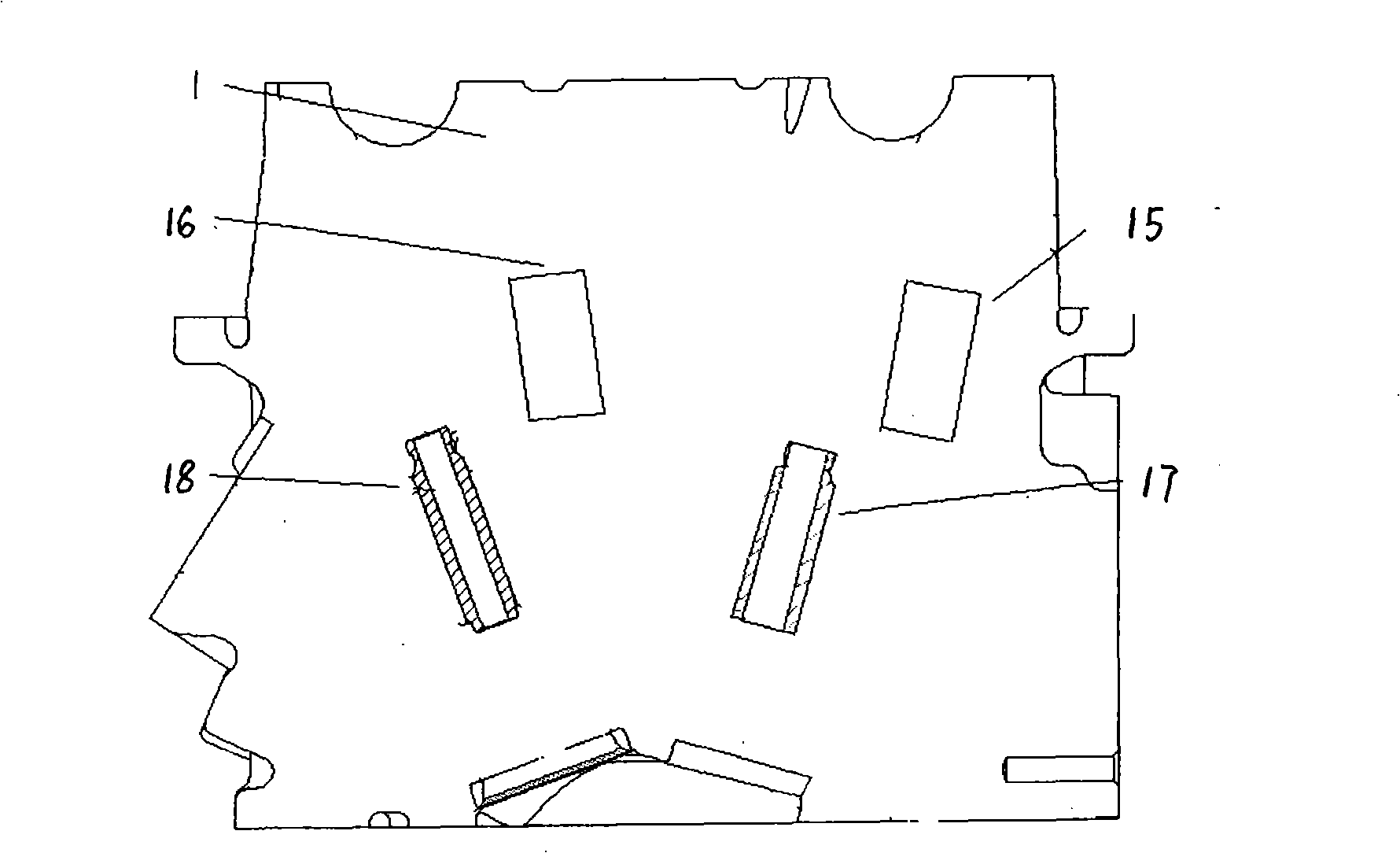

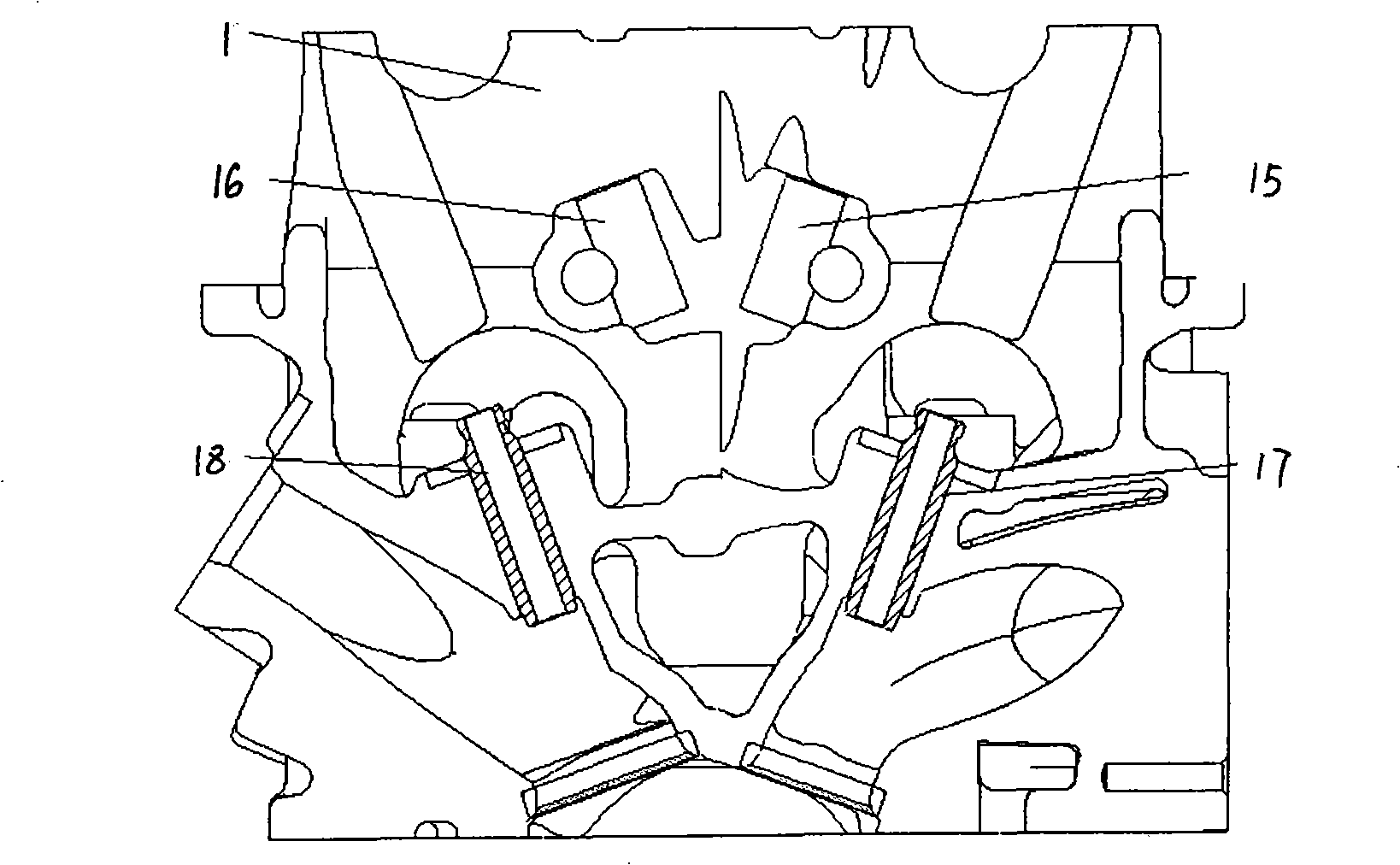

[0013] see image 3 The cylinder head 1 of the arrangement structure proposed by the present invention is to arrange the intake hydraulic tappet hole 16 and the intake valve guide hole 18 in parallel in each group (only one group is shown in the figure), and the exhaust hydraulic tappet hole 15 and the intake valve guide hole 18 are arranged in parallel. The exhaust valve guide holes 17 are arranged in parallel. And the intake hydraulic tappet hole 16 and the exhaust hydraulic tappet hole 15 in each group are symmetrically arranged along the same central line A perpendicular to the horizontal plane; the intake valve guide hole 18 and the exhaust valve guide hole 17 are also arranged vertically The same central line A of the horizontal plane is symmetrically arranged left and right.

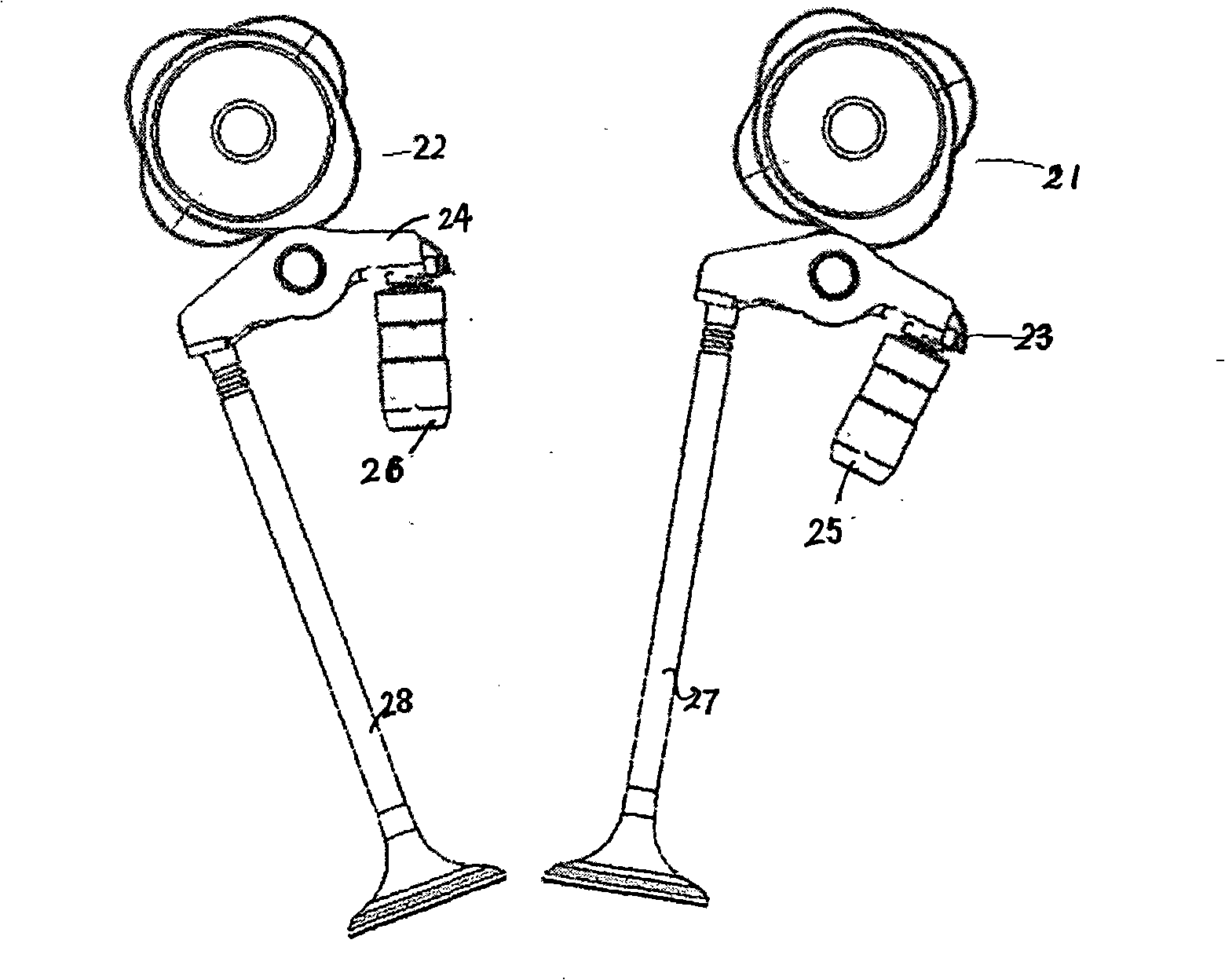

[0014] For valve trains mounted in the cylinder head see Figure 4 , the intake hydraulic tappet assembly 26 is arranged parallel to the intake valve 28, the exhaust hydraulic tappet assembly 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com