Inflating apparatus

A technology of an inflatable device and a control device, which is applied to pump devices, liquid variable displacement machines, non-variable displacement pumps, etc., and can solve problems such as low efficiency, unfavorable air leakage, and failure of air compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

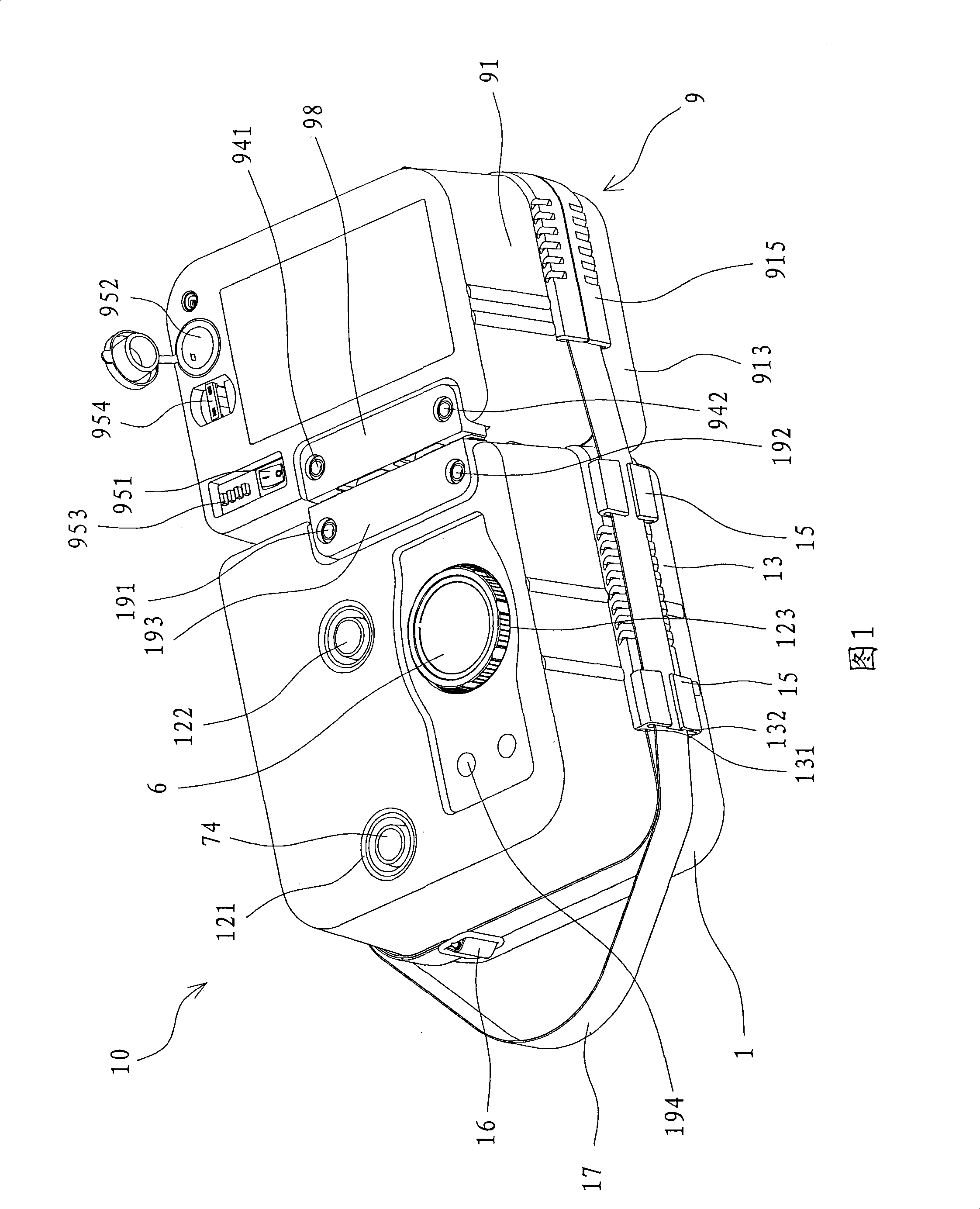

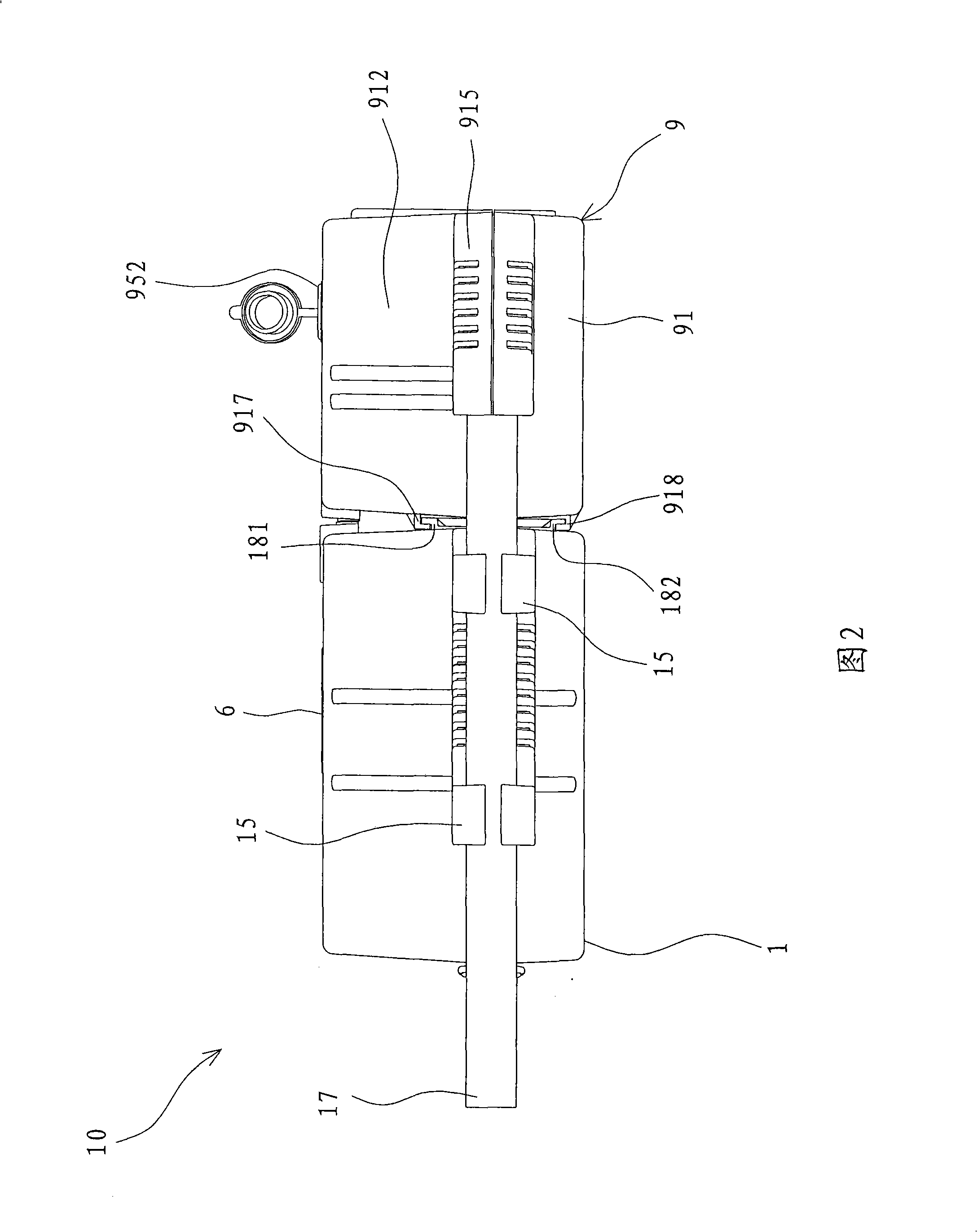

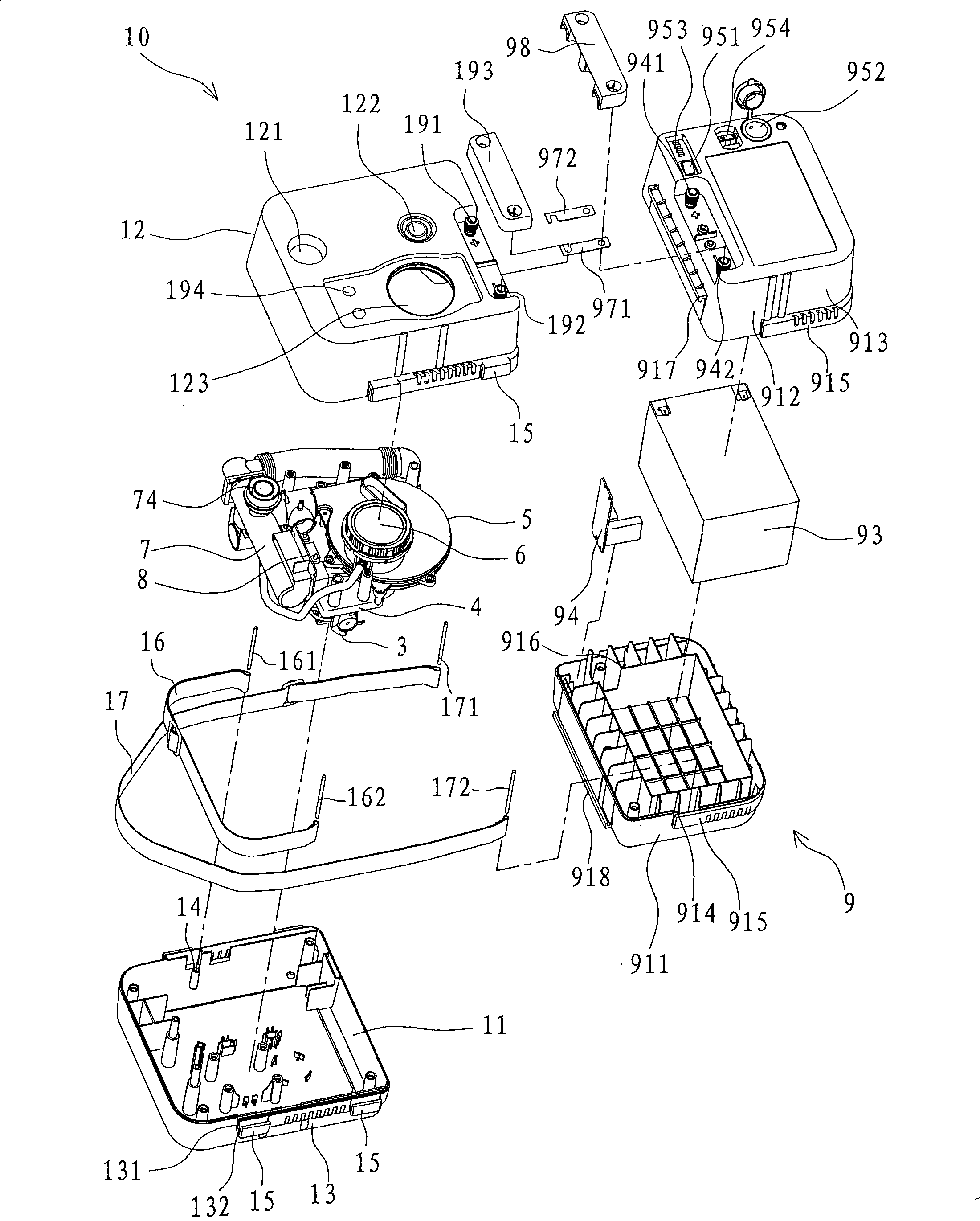

[0057] Refer to Figure 1 to image 3 Shown is an inflatable device 10 composed of a preferred embodiment of the present invention, including a box body 1, a first gas compression device 5, a second gas compression device 3, a gas storage pipe 7, and a control device 8 And a battery device 9 .

[0058] In this embodiment, the box body 1 is composed of a lower cover 11 with an opening upward and an upper cover 12 with an opening downward; two opposite side walls 13 of the box body 1 have a first belt hole 131 and a first Two belt holes 132, the two belt holes 131, 132 are defined by the inside of the L-shaped flap 15 extending outward from the side wall 13, and the second belt hole 132 is located outside the first belt hole 131; wherein, the first The belt hole 131 can pass through the first belt body 16, and the two ends of the first belt body 16 are respectively fixed in the fixing holes 14 provided inside the lower cover 11 by two bolts 161, 162, and the second belt hole 132 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com