Method for covering cathode cover by sealing ring of alkaline button cell

A button battery and negative electrode cover technology, which is applied to battery components, circuits, electrical components, etc., can solve problems such as low efficiency, battery swelling and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

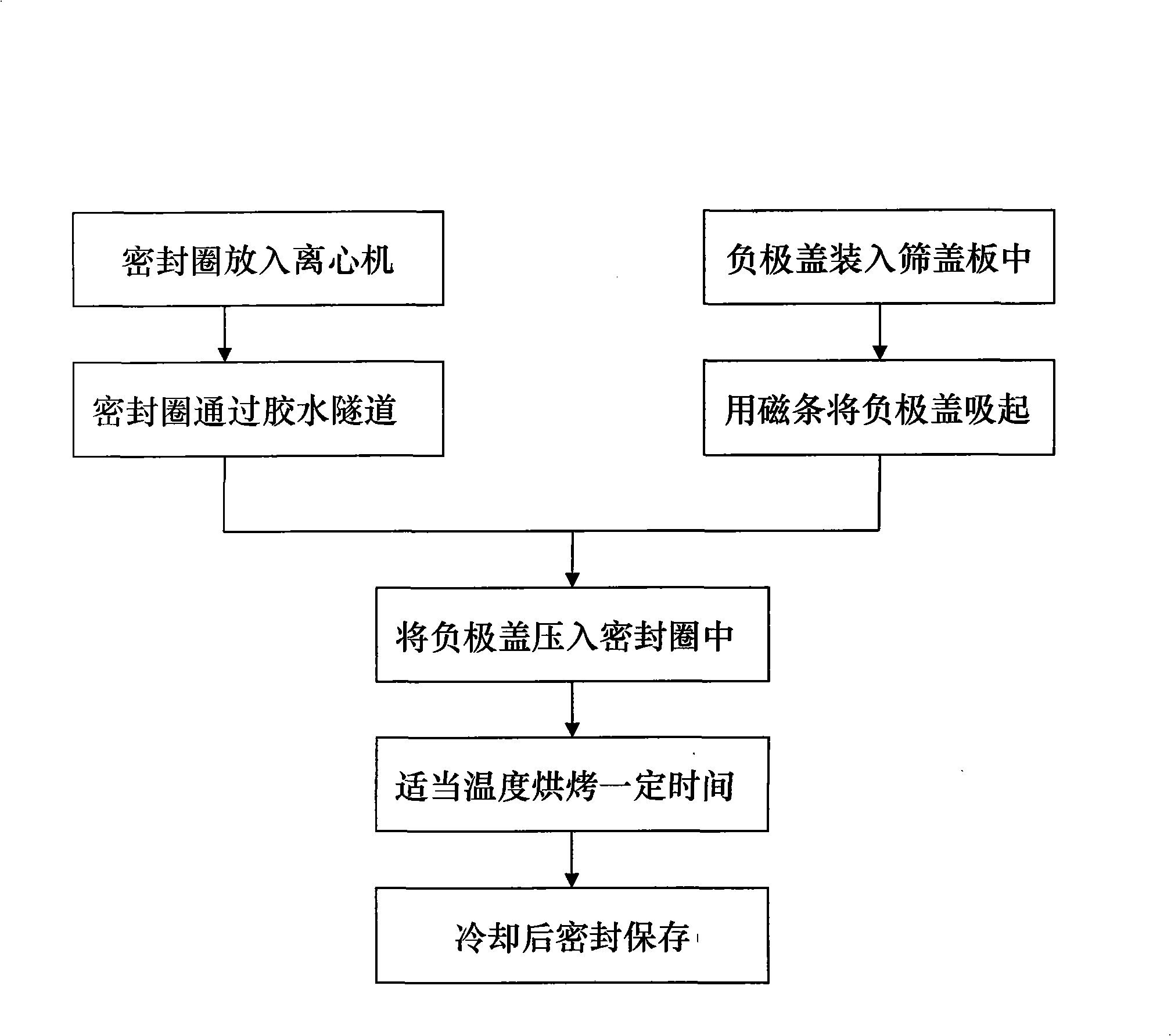

[0012] See figure 1 As shown, put the sealing ring of the alkaline button battery into the centrifugal vibrating plate that starts, and the sealing ring of the alkaline battery will pass through the tunnel with the sealing glue with a glue content of 10-20% one by one in the upward direction of the mouth. The magnetic strip with a width of 2-6mm will suck up the negative electrode cover installed in the sieve cover plate, and forcefully press the negative electrode cover into the sealing ring that has passed through the glue tunnel, so that the negative electrode cover and the sealing ring cooperate well, and then pass through 50-60 Bake for 30-180 minutes at a temperature of ℃, after cooling, pack it into a bag and seal it for storage, and then put it into assembly production.

Embodiment approach 2

[0014] Push the sealing rings one by one into the tunnel filled with 10-20% sealing glue by hand in the upward direction of the mouth, use a magnetic strip with a width of 2-6mm to suck up the negative electrode cover, and press the negative electrode cover firmly Insert the sealing ring to make the negative electrode cover and the sealing ring that have passed through the glue tunnel fit well, and then bake at a temperature of 50-60°C for 30-180 minutes. After cooling, pack it into a bag and seal it for storage, and then put it into assembly production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com