Low-noise stator core stamping sheet

A stator core, low-noise technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve problems such as no reports on stator structure improvement, and achieve noise problem improvement, quality improvement, and noise reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

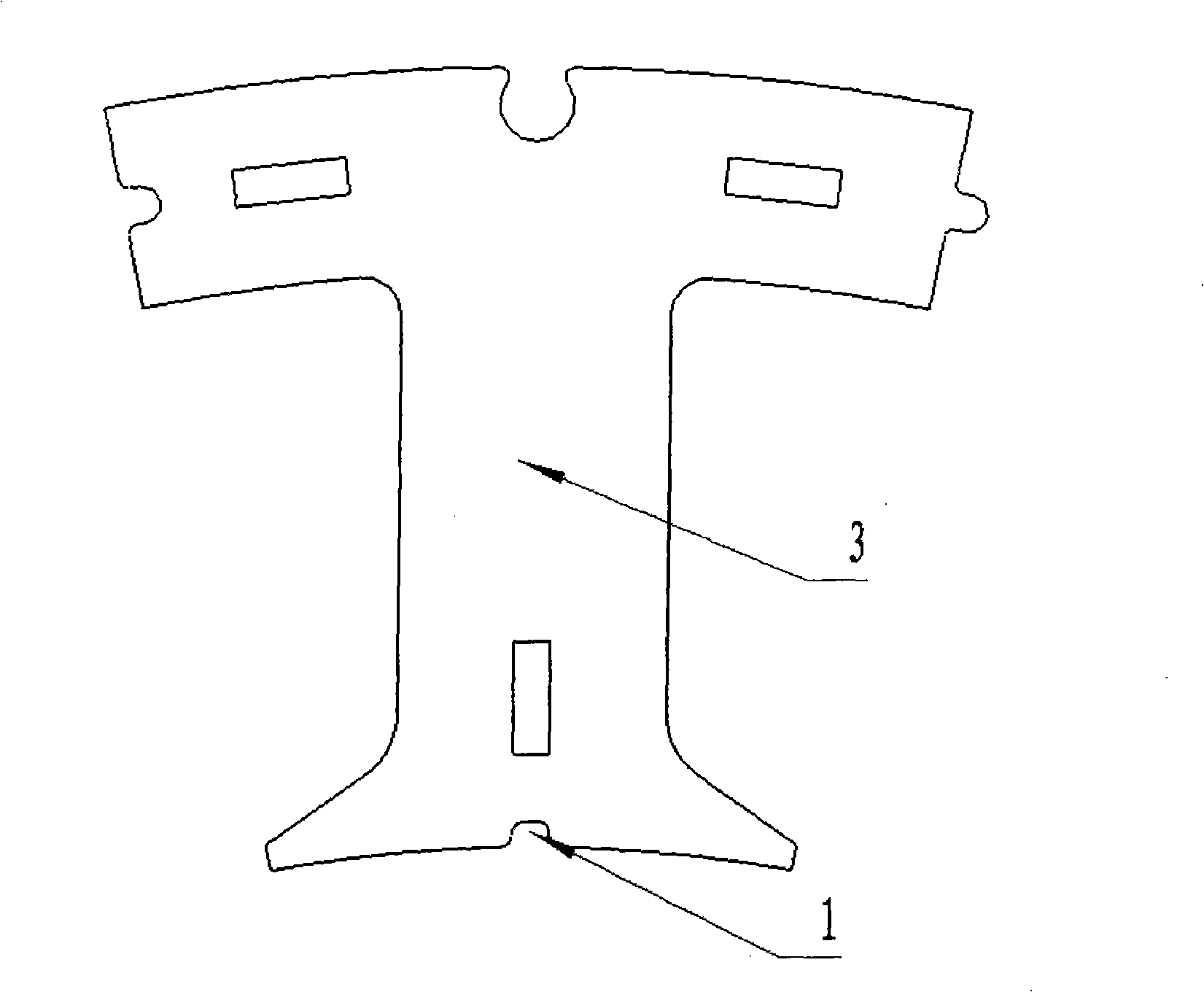

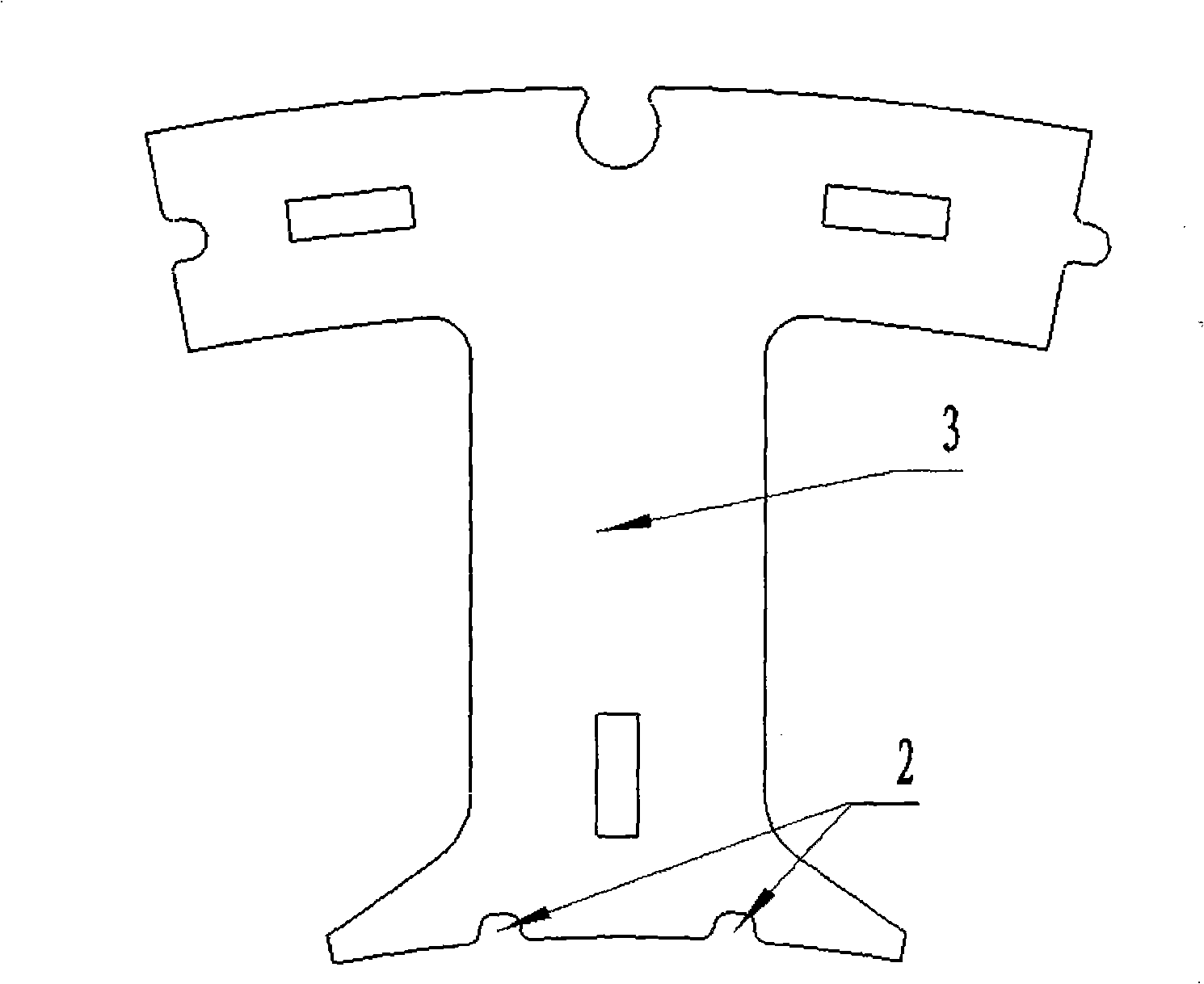

[0009] The present invention is mainly composed of the stator iron core punching sheet 3, the virtual slot opened on the pole shoe at the bottom of the stator iron core punching sheet 3, and the like.

[0010] Depending on the number of poles of the motor, 1 to 3 virtual slots can be opened, for example, a virtual slot 1 is opened at the center of the pole shoe at the bottom of the stator core punch 3 of an 8-pole machine, and at the bottom of the stator core punch 3 of a 6-pole machine Two virtual slots 2 are evenly opened on the pole piece. During processing, first make a mold according to the design requirements, and then punch out the required punching sheet. During the punching process, through equipment control, the required stator core is automatically laminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com