Thin-film type solar cell including by-pass diode and manufacturing method thereof

A technology of solar cells and thin films, applied in the direction of diodes, circuits, electrical components, etc., can solve problems such as current limitation and hot spots, and achieve huge economic value and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

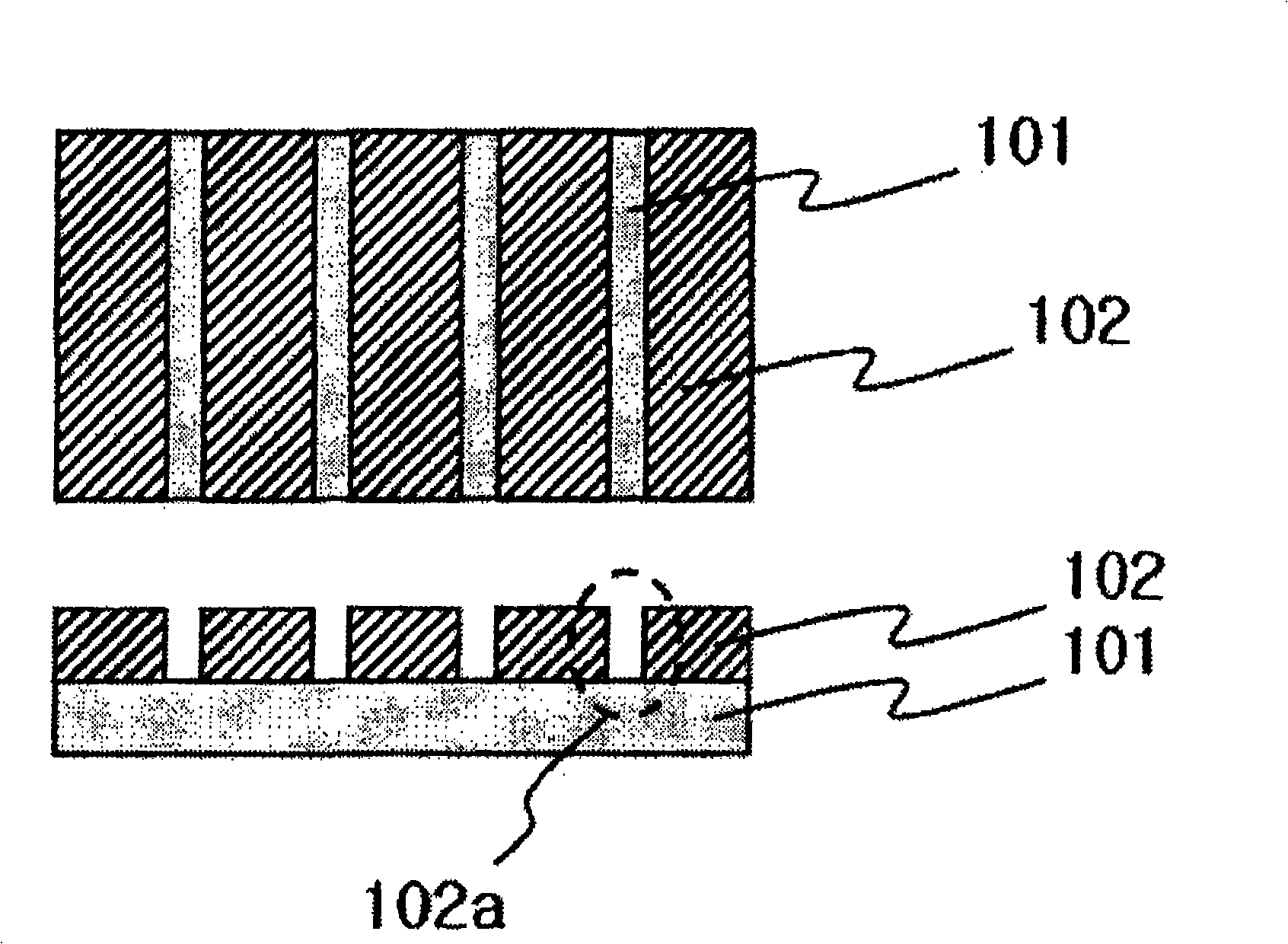

[0059] For the basis Figure 9 to Figure 1 One embodiment of the invention of 5 considers two unit solar cell modules.

[0060] Each unit solar cell module is composed of a plurality of unit solar cells arranged in a row.

[0061] Figure 13 A patterning process of the photoelectric conversion layer 303 is shown. First, patterning for separating the photoelectric conversion layer 303 into two unit solar cell modules is performed.

[0062] In other words, the patterning 303c of separating the photoelectric conversion layer into the upper unit solar cell module 303b and the lower unit solar cell module 303a is performed. Patterning may be performed in left and right directions to separate the photoelectric conversion layer into an upper unit solar cell module and a lower unit solar cell module.

[0063] In order to form unit solar cells in the unit solar cell modules separated up and down, each photoelectric conversion layer corresponding to the upper unit solar cell module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com