Tridimensional spunlace jacquard nonwoven cloth dishcloth

A technology of non-woven fabrics and rags, which is applied in non-woven fabrics, textiles, papermaking, and carpet cleaning, etc. It can solve the problems of making non-woven rags, etc., and achieve the effect of clear mesh and improved product grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

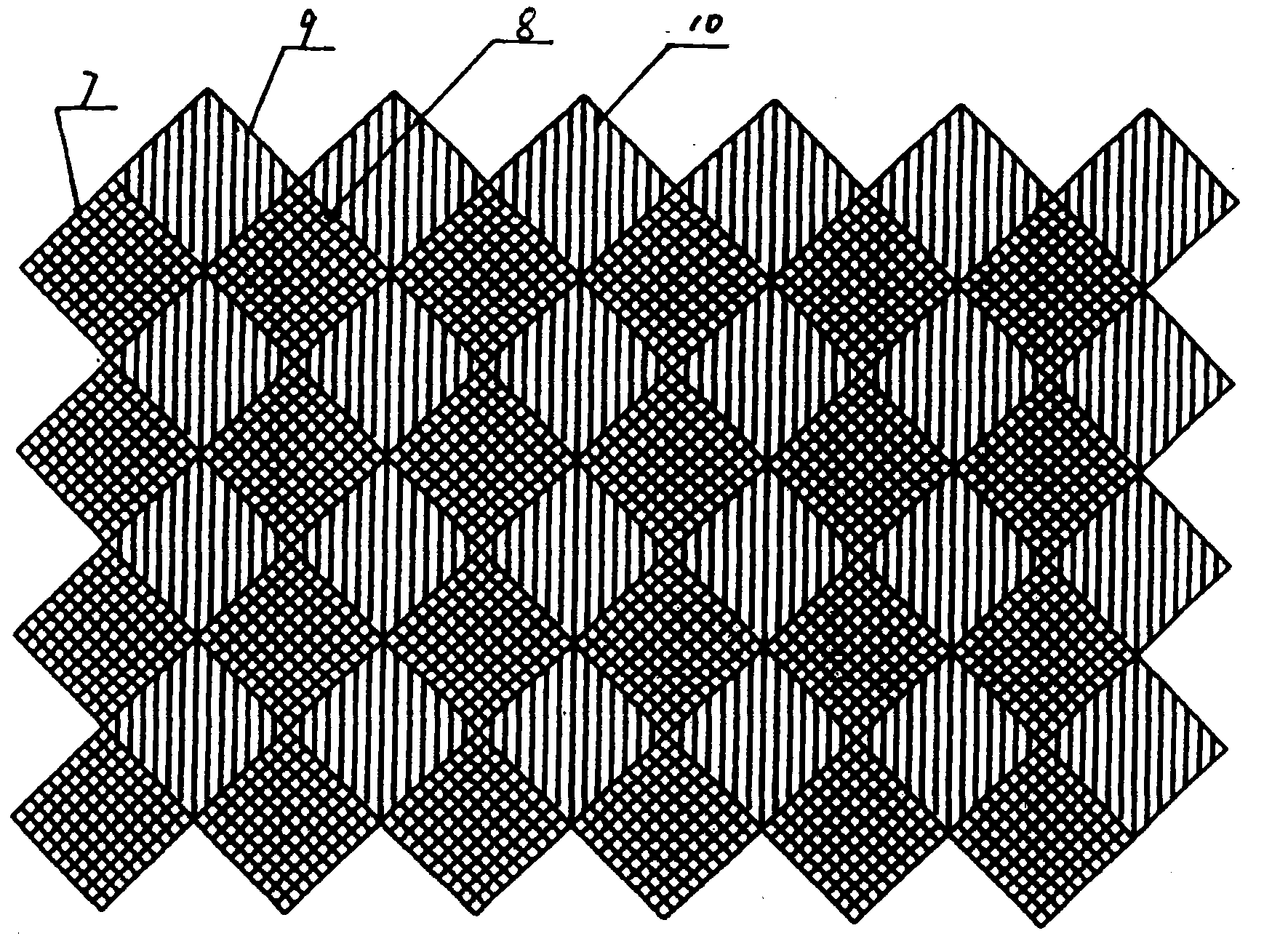

[0011] Embodiment 1: with reference to accompanying drawing 1. Concave-convex non-woven cloth, the surface of the non-woven cloth has a concave-convex three-dimensional block structure, and the corners of the concave-convex three-dimensional block are connected with each other or the edges are connected with each other. The surface of the convex part 7 in the non-woven cloth is densely covered with tiny bumps 8 or densely covered with a plurality of raised convex lines 10, and the surface 9 of the concave part is densely covered with a plurality of thin convex lines 10 or densely covered with tiny bumps 8. Ventilation holes are densely covered on the non-woven fabric between the micro bumps and the micro bumps 8, and vent holes are densely covered on the non-woven fabric between the thin convex strips.

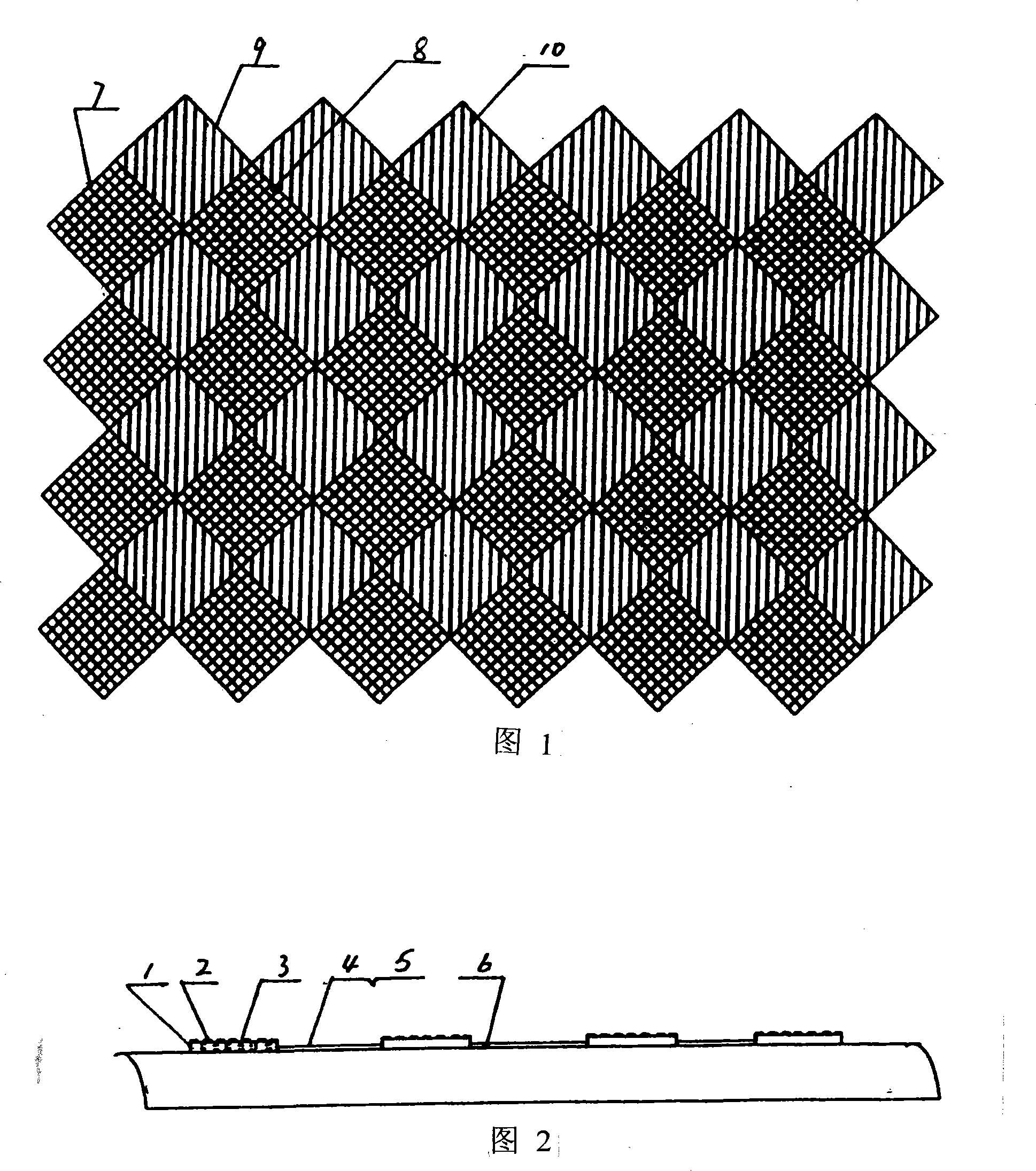

[0012] The production equipment of the above-mentioned concave-convex non-woven cloth rag adopts a three-dimensional spunlace jacquard drum punching die. Block 2 or densely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com