Optical reading head with diffuseness structure

An optical read head and structure technology, applied in the field of optical read heads, can solve the problems of inability to effectively improve lighting efficiency, reduce LED usage and power consumption, and reduce contrast, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

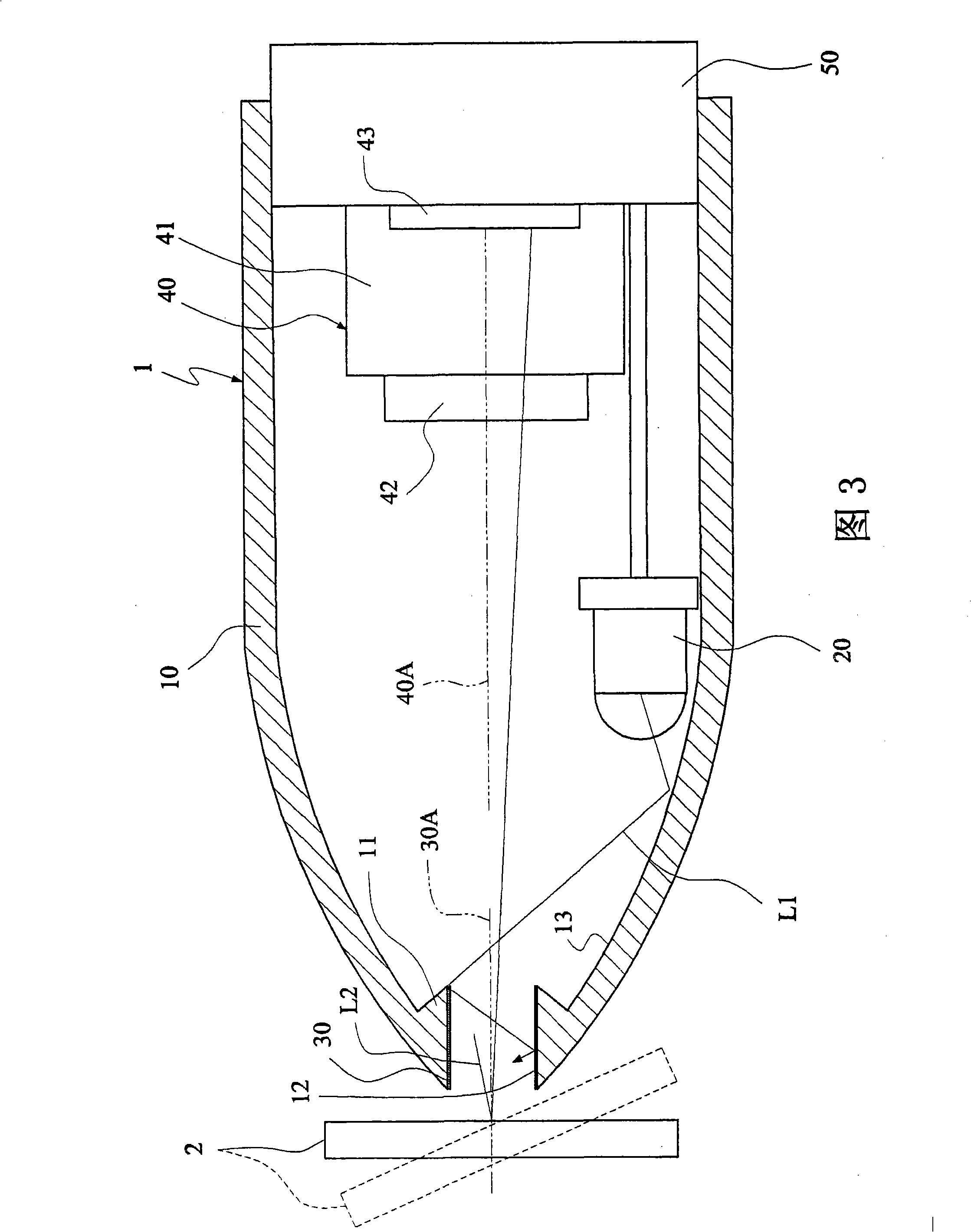

[0033] FIG. 3 is a schematic diagram showing the application of the optical pickup head according to the first embodiment of the present invention. As shown in FIG. 3 , the optical pickup head 1 of this embodiment is used to read an object 2 . The object 2 is, for example, an electronic book, on which a pattern such as a two-dimensional barcode is printed. The optical pickup head 1 includes a hollow shell 10 , a light source module 20 , a diffusion structure 30 and a photosensitive module 40 .

[0034] The light source module 20 is fixed in the hollow casing 10 and provides an initial light L1. The light source module 20 includes but not limited to one light emitting diode or a plurality of light emitting diodes. Multiple LEDs can emit the same light or different lights. In this embodiment, a light emitting diode is taken as an example for illustration, and the initial light L1 is reflected by an inner wall surface 13 of the hollow casing 10 into the diffusion structure 30 ...

no. 2 example

[0040] This embodiment uses a tubular diffuser structure to provide uniform light.

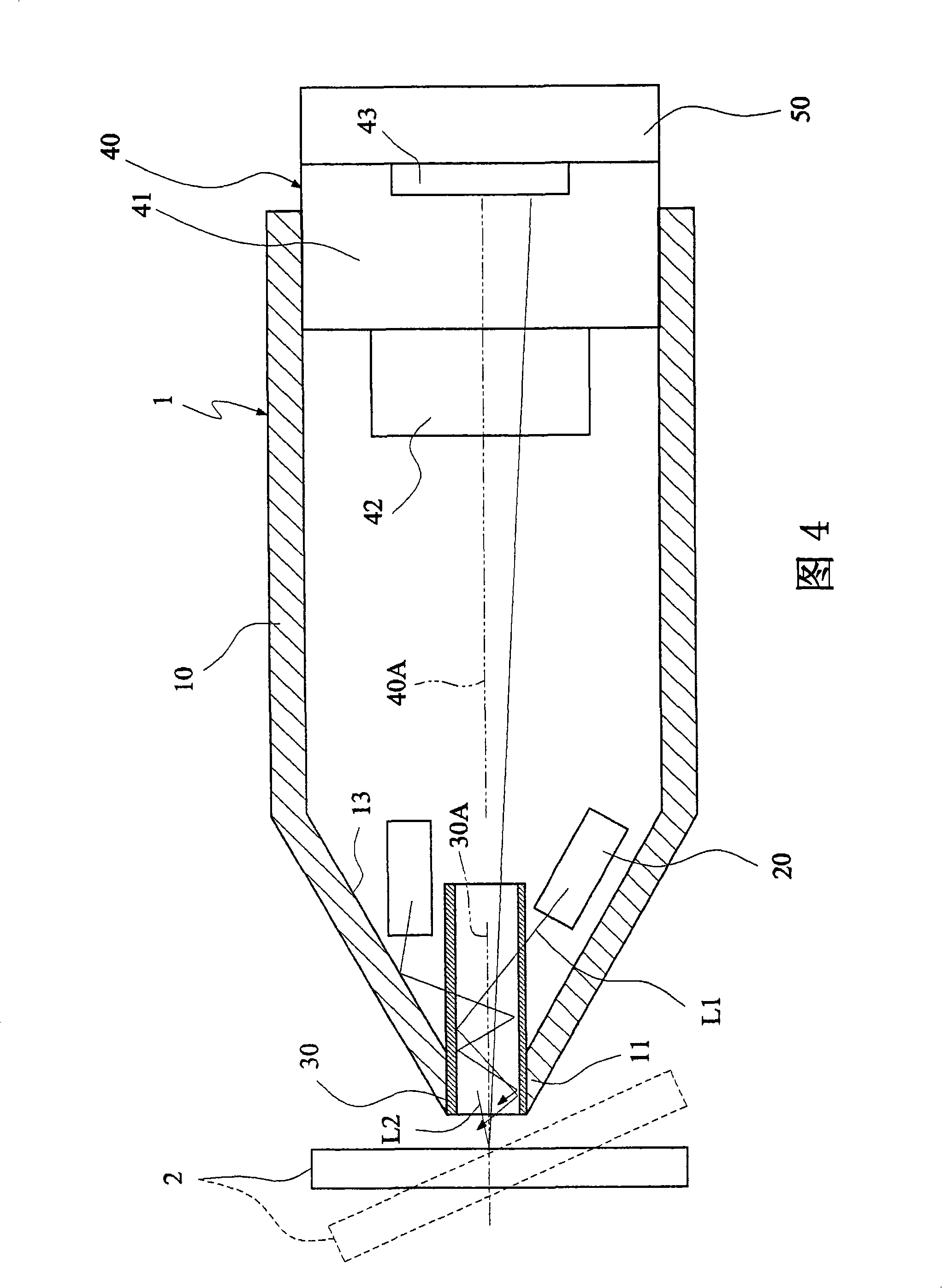

[0041]FIG. 4 is a schematic diagram showing the application of the optical pickup head according to the second embodiment of the present invention. As shown in Figure 4, the optical pickup head of this embodiment is similar to the first embodiment, the difference is that the diffusion structure 30 is a hollow tube, which is installed in an opening of the hollow shell 10 11. Therefore, the initial light L1 first refracts and penetrates into the diffusion structure 30 , and then performs reflection in the diffusion structure 30 . It should be noted that the diffusion structure 30 can be a solid cylinder. The solid cylinder helps to isolate the outside dust from the photosensitive module 40 . Alternatively, the diffusion structure 30 may be composed of a hollow tube and a transparent member for sealing the hollow tube. Wherein, the diffuse structure can be made by adding white dye to PC, acry...

no. 3 example

[0044] In this embodiment, uniform light is provided by a tubular diffuser structure combined with a light integration structure.

[0045] FIG. 5 is a schematic diagram showing the application of the optical pickup head according to the third embodiment of the present invention. As shown in FIG. 5 , the optical pickup head of this embodiment is similar to the first embodiment, the difference is that the diffusion structure 30 is installed in an opening 11 of the hollow casing 10 and the hollow casing 10 An inner retaining edge 14 of. Thus, the diffuser structure 30 , the hollow casing 10 and the inner retaining edge 14 can form a closed space 15 for use as a light integrating structure. And cooperate with the diffusion structure 30 to provide more uniform light.

[0046] In this embodiment, the light emitting diodes of the light source module 20 are located in the confined space 15, and the initial light L1 first refracts and penetrates the diffusion structure 30, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com