Cutting or etching device with tool provided with impeller for suction of dust

A technology of cutting tools and impellers, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve the problems of mechanical stress, inappropriate power, and environmental pollution of cutting heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

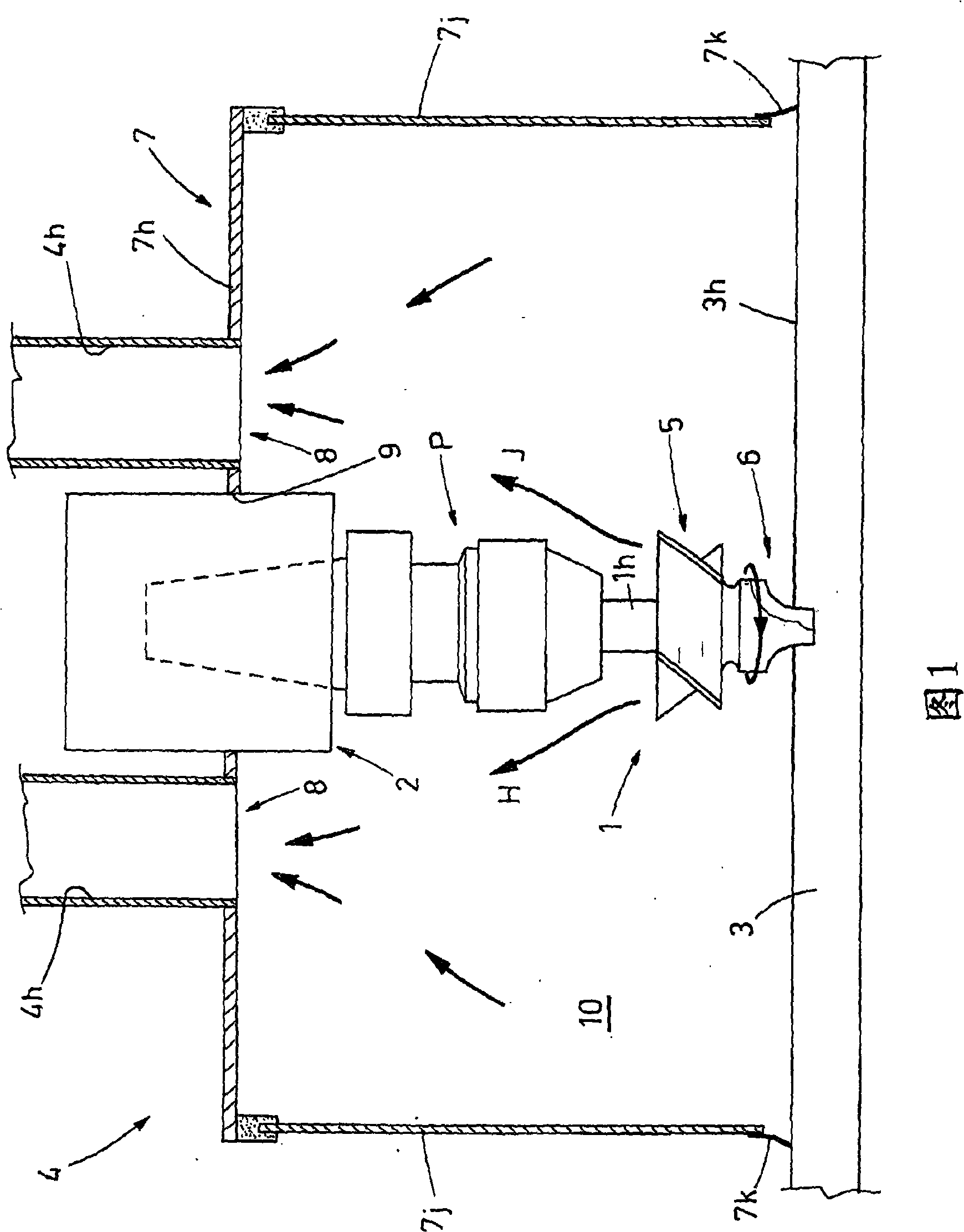

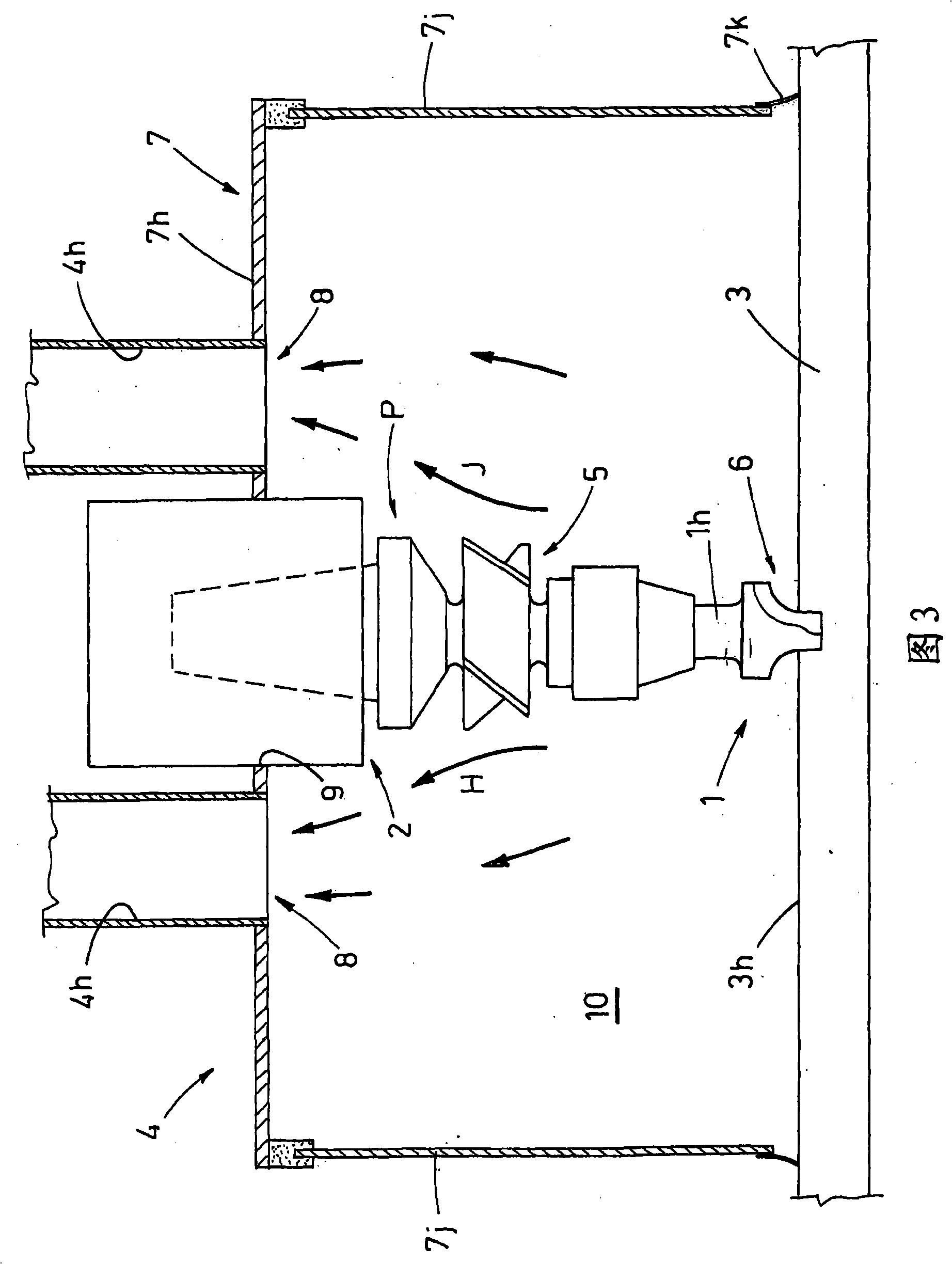

[0026] Attention is drawn to the drawings, reference numeral 1 designates a tool, which is driven in rotation by a spindle 2 connected to a drive mechanism of the machine tool, which is not shown because it is not relevant to the invention.

[0027] In particular, in the example shown, the tool holder element P is functionally interposed between the tool 1 and the spindle 2 ( FIG. 1 ).

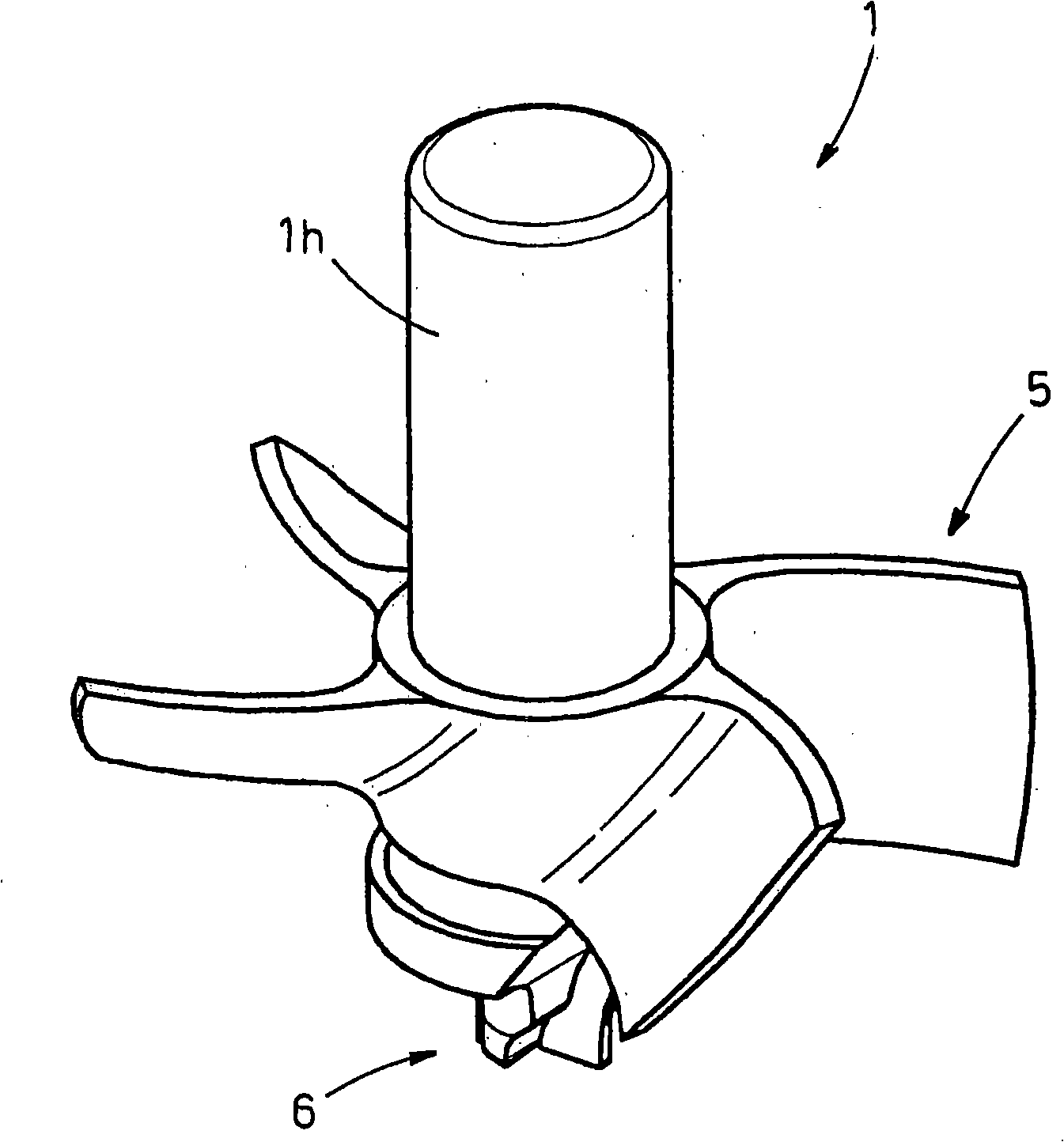

[0028] The cutter 1 comprises a shank 1h, the lower end of which forms a head 6 for cutting and / or etching objects, such as wood boards, and the shank 1h is equipped with an impeller 5 coaxial therewith, positioned above the head 6, and The key is fixed to the shank 1 h, or is integral with the knife 1 .

[0029] In the example shown, the impeller 5 has 4 blades arranged in two identical blade pairs (see figure 2 ), the two blade pairs are angularly equidistant.

[0030] Figure 1 shows a cover generally indicated at 7, formed by an upper part 7h, ie a cover plate, and side walls 7j, ending i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com