Drum cleaning program control method for full automatic washing machine

A fully automatic washing machine and tub cleaning technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problem of dirt residue in the tub of the fully automatic washing machine, and achieve the effect of cleaning the internal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

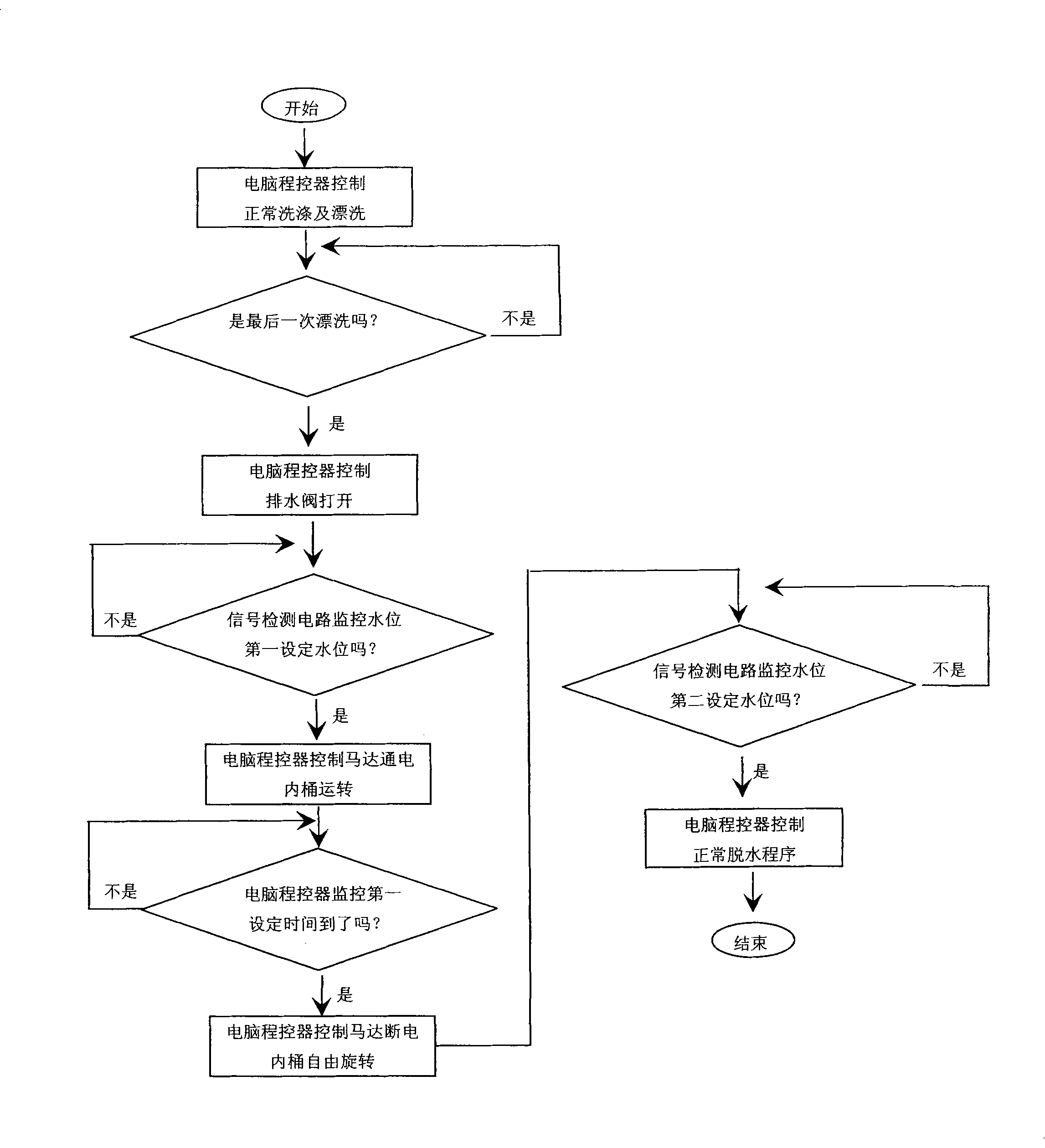

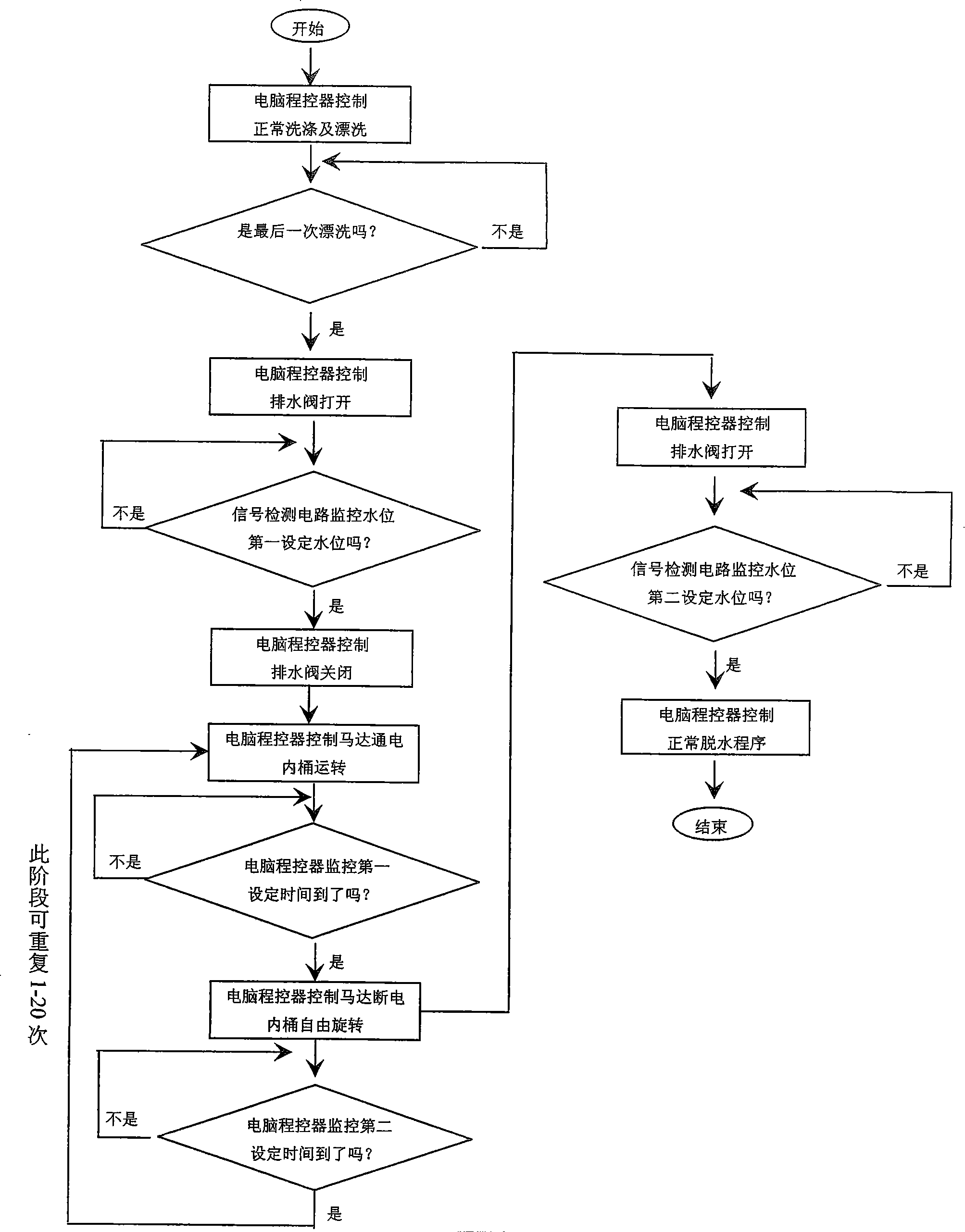

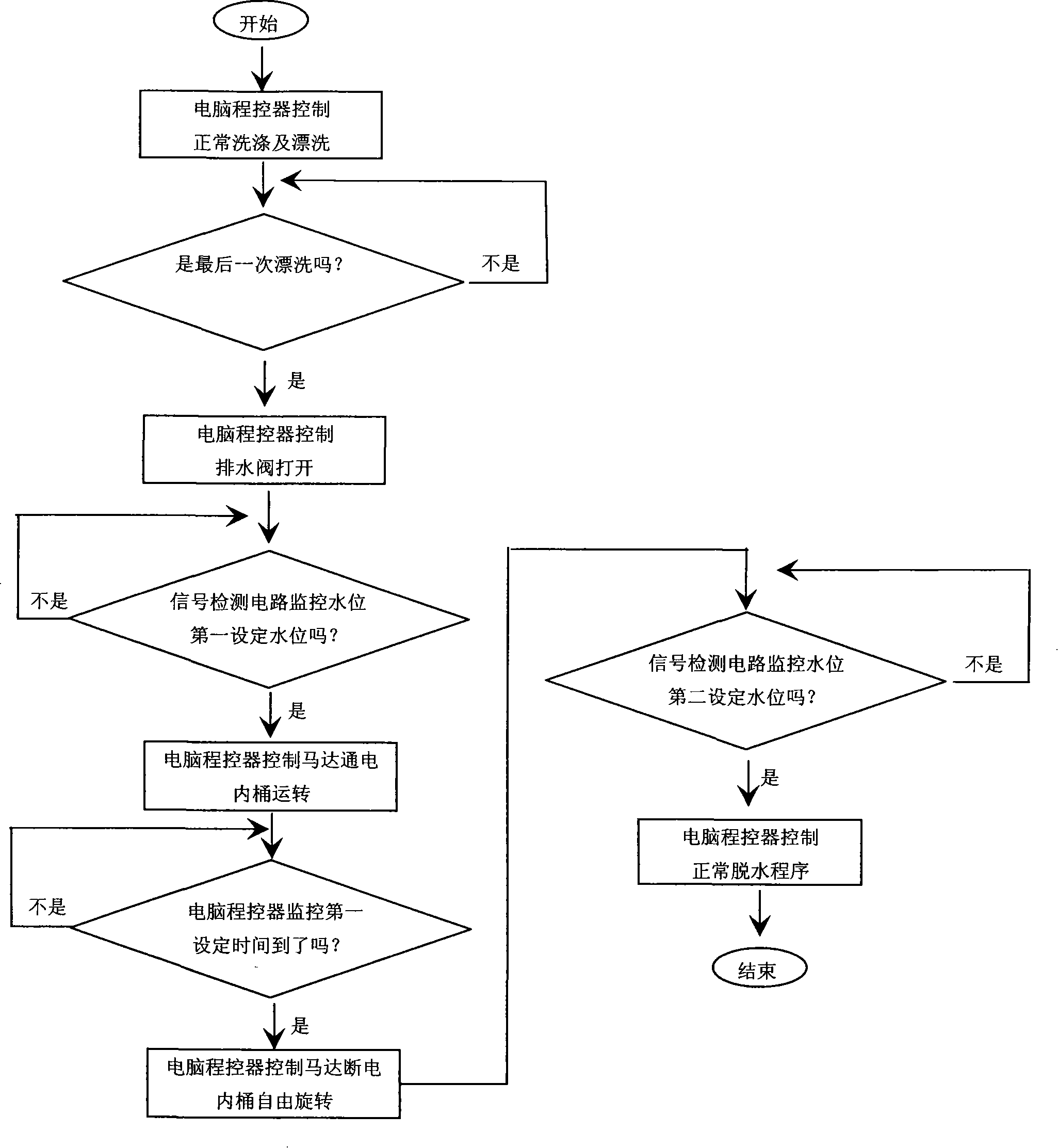

[0019] The method for controlling the cleaning program of the fully automatic washing machine tub of the present invention will be further specifically described below through examples and in conjunction with the accompanying drawings.

[0020] The present invention is different from the prior art by changing the control method of draining water and rotating the inner barrel of the fully automatic washing machine, so that the outer side of the inner barrel, the inner side and the bottom surface of the outer barrel of the full-automatic washing machine are cleaned.

[0021] Inventive program control as shown in Figure 1 and Figure 3: the computer program controller 1 fixed in the washing machine control seat is the control part of the whole program, controlling the actions of parts such as motor 5, drain valve 6 and water level controller 7. Outer barrel 2 is a water-holding part, and drain valve 6 and motor 5 are fixed on it; Inner barrel is made up of stainless steel upper bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com