LED lamp strip and LED screen body

A technology of LED light strips and LED screens, which is applied in the direction of electric lamp circuit layout, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of poor decoration effect, high power consumption, and bulky PCB board, etc., to achieve Obvious decorative effect, high reliability and changeable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

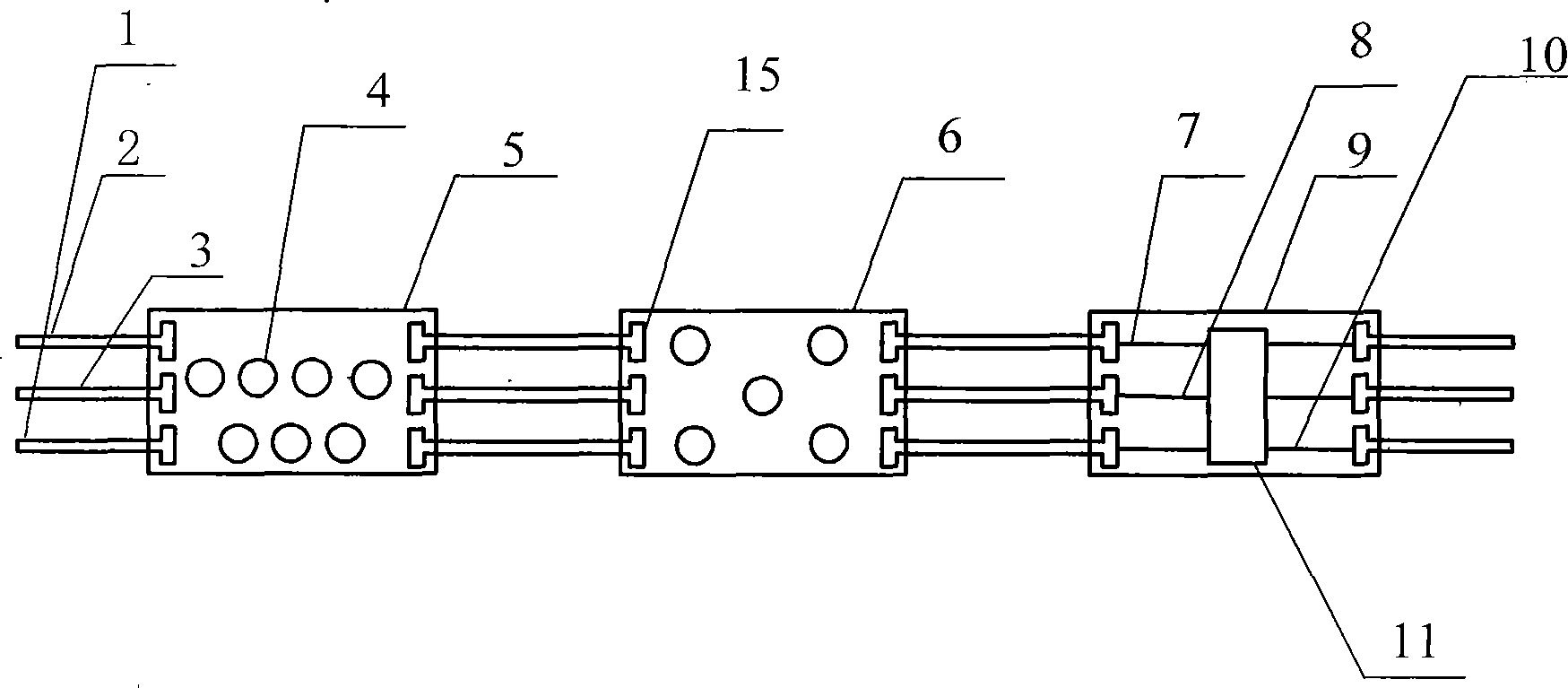

[0037] like figure 1 As shown, in this embodiment, the LED light bar is composed of LED light-emitting unit 5, LED light-emitting unit 6 and LED light-emitting unit 9, through rigid exposed connecting wire 1, rigid exposed connecting wire 2, and rigid exposed connecting wire 3. Adjacent LED light-emitting units are connected; in this embodiment, the rigid exposed connecting wire 1 is used as the signal line, the rigid exposed connecting wire 2 is used as the positive electrode line, and the rigid exposed connecting wire 3 is used as the negative electrode line; the three rigid exposed connecting wires can also be used according to different According to the needs of different circuits, the two ends of the rigid exposed connecting line 1, the rigid exposed connecting line 2, and the rigid exposed connecting line 3 are respectively provided with a clamping part 15, and the cross section of the clamping part 15 is T-shaped, or it can be considered The longitudinal cross-section o...

Embodiment 2

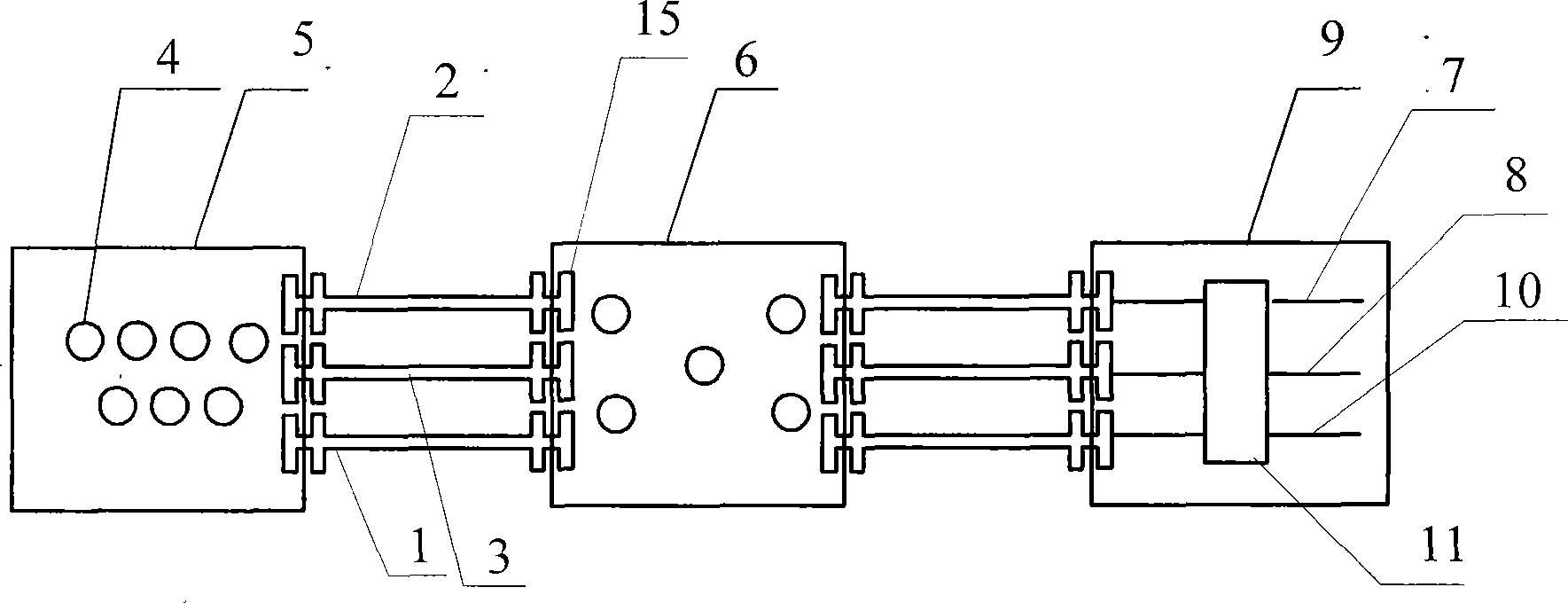

[0045] like figure 2As shown, in this embodiment, the LED light bar is composed of LED light-emitting unit 5, LED light-emitting unit 6 and LED light-emitting unit 9, through rigid exposed connecting wire 1, rigid exposed connecting wire 2, and rigid exposed connecting wire 3. Adjacent LED light-emitting units are connected; the two ends of the rigid exposed connecting line 1, the rigid exposed connecting line 2, and the rigid exposed connecting line 3 are respectively provided with clamping parts 15. In this embodiment, the rigid exposed connecting line 1 is used as a signal line , The rigid exposed connecting wire 2 is used as the positive wire, and the rigid exposed connecting wire 3 is used as the negative wire;

[0046] The cross-section of the clamping part 15 is dry-shaped, and three bayonet parts are respectively arranged on the corresponding sides of the housing of the LED light emitting unit, and 4 or more can also be provided, mainly depending on the number of rigi...

Embodiment 3

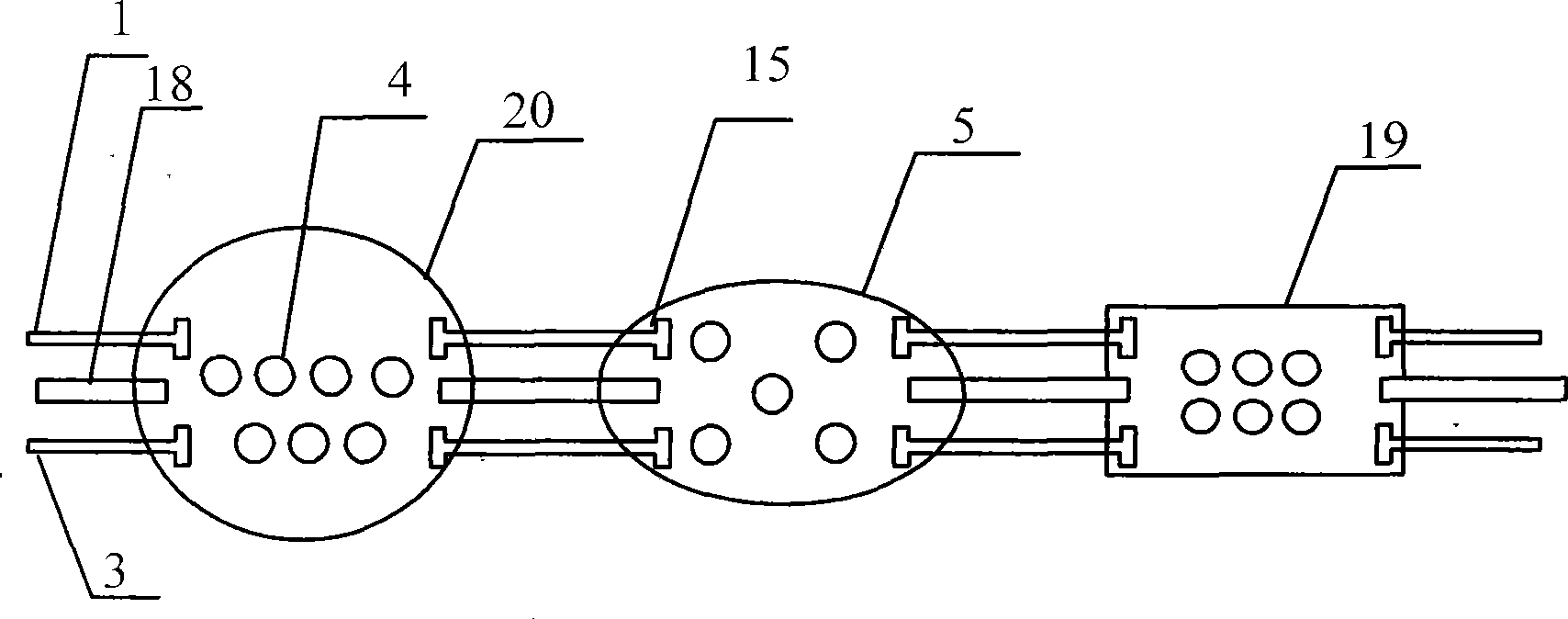

[0056] like image 3 , Figure 4 As shown, in this embodiment, the LED light bar is composed of an oval LED light emitting unit 5, a circular LED light emitting unit 20 and a square LED light emitting unit 19, through the rigid connecting wire 1, the rigid connecting wire 3, and the rigid connecting wire 18, Connect two adjacent LED light-emitting units; in this embodiment, the rigid connection line 18 is a relatively long pass bar with respect to the rigid connection line 1 and the rigid connection line 3, and there is no intermittent; for example, for an LED light bar, the rigid connection line 18 is connected from the LED light emitting unit at one end of the light bar to the LED light emitting unit at the other end; it should be noted that no matter what shape the LED light emitting unit is used, The technical solution of using a cleaning rod is applicable to any embodiment of this specification. The above cleaning strips can be widened and thickened to be used as load-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com