Steel plastic combined artificial rain bullet detonator

A fuze, steel-plastic technology, applied in the field of rain bomb fuze, can solve the problems of small mass, large mass of explosion residual fragments, half-explosion, etc., and achieve the effect of reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

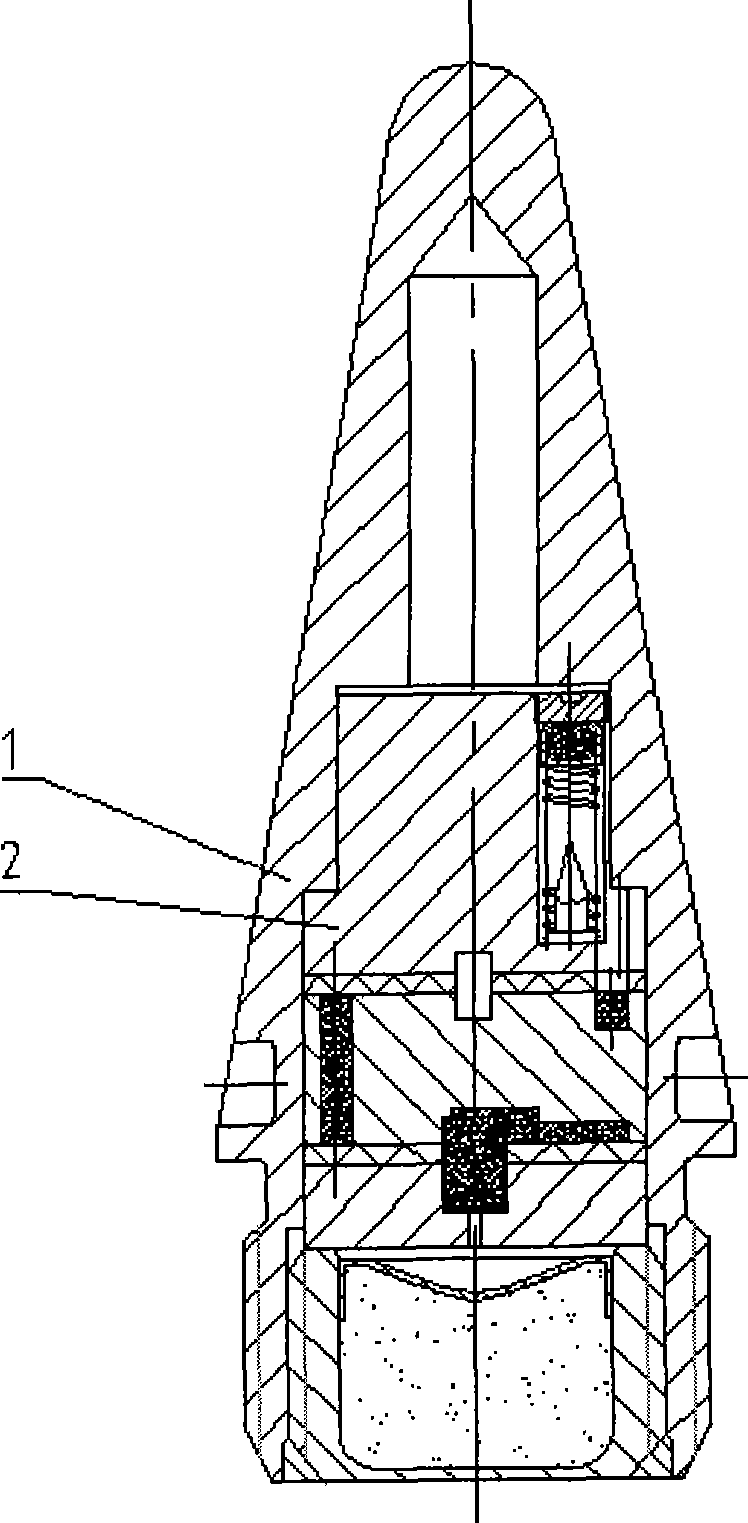

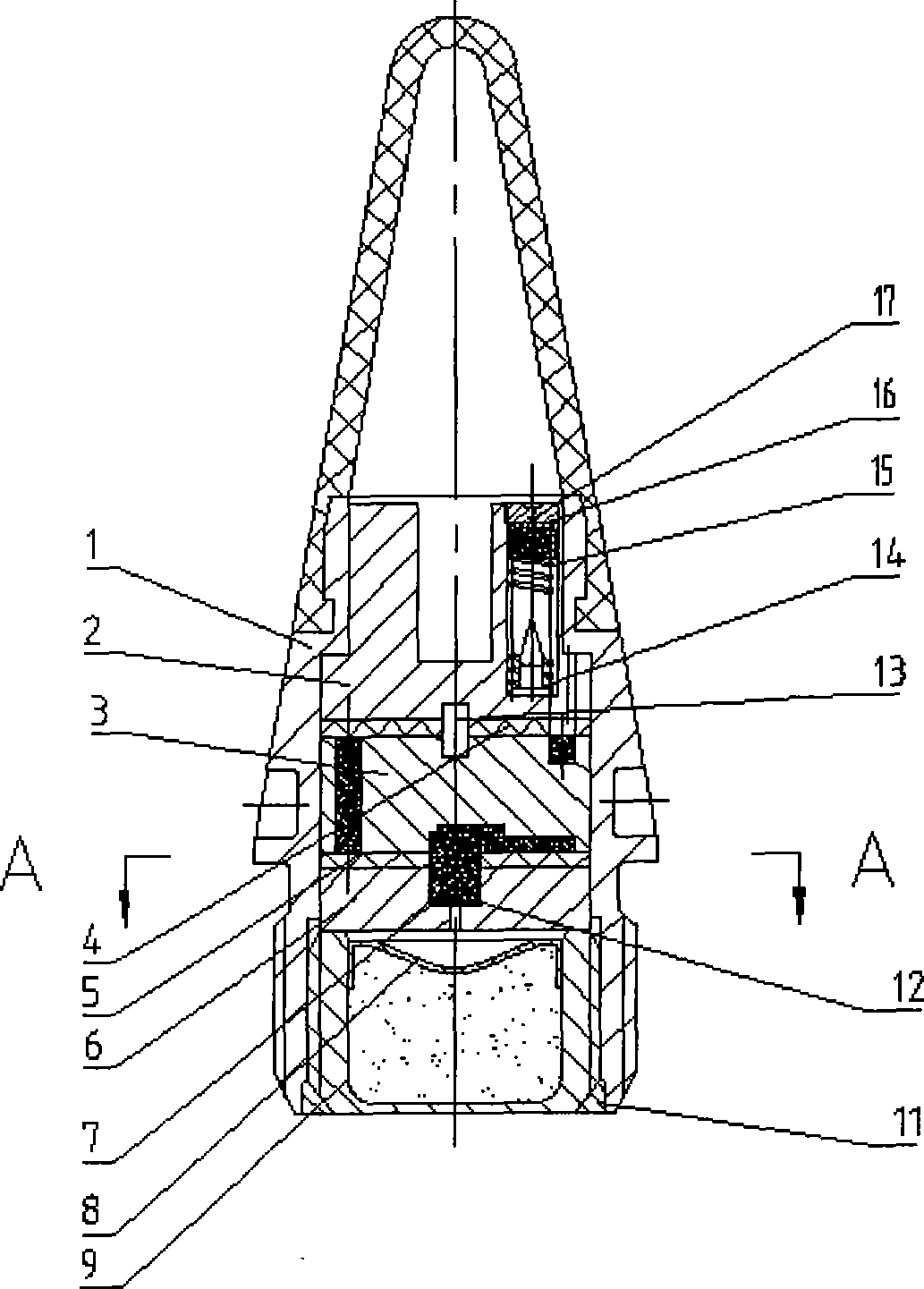

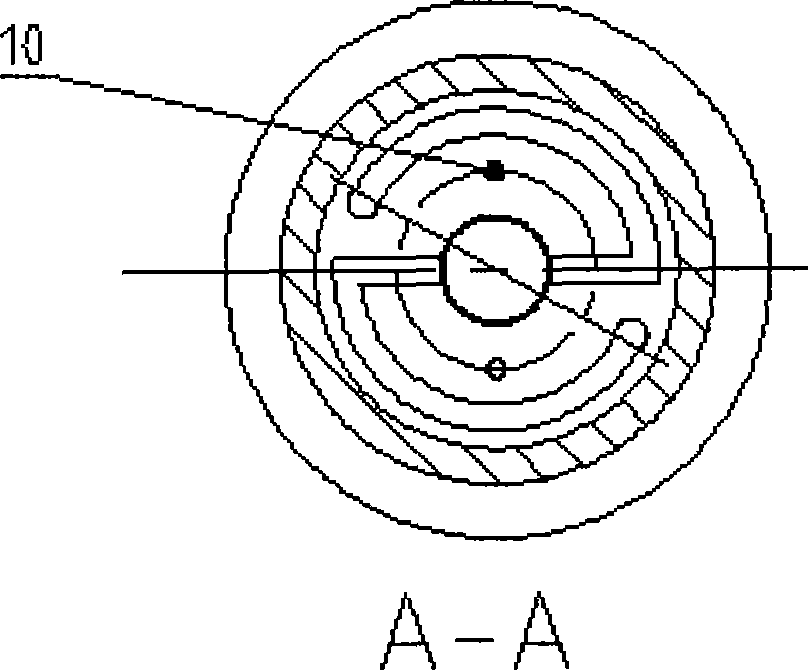

[0012] Such as figure 2 with image 3 As shown, the steel-plastic combined rain bomb fuze is composed of a fuze body, a side firing mechanism, a time-delayed self-destruct mechanism and a detonator tube.

[0013] The fuze body 1 is divided into a lower steel body part 1-1 and an upper injection-molded plastic part 1-2. The steel body part is machine-added molding of No. 30 steel, and the upper plastic part is molded by injection molding. The plastic material is modified reinforced nylon SL-007 , the injection molding condition is that the plastic part is dried for 16h~24h and then preheated to 85°C±5°C, and then the steel part of the fuze body is preheated to 85°C±5°C, and the injection molding is carried out under the pressure of 90MPa~110MPa in the injection molding machine.

[0014] The time-delay self-destruct mechanism is composed of an upper positioning pin 13, an upper paper gasket 4, a medicine tray 3, a lower paper gasket 5, an adjusting paper pad 7, a lower positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com