Chip type balance-unbalance transformer

A balanced transformer and balanced technology, applied in transformers, fixed transformers, transformers/inductor coils/windings/connections, etc., can solve the problem that the winding turns ratio cannot be improved, the impedance conversion ratio is enlarged, and the wiring space is large. Energy conversion loss And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

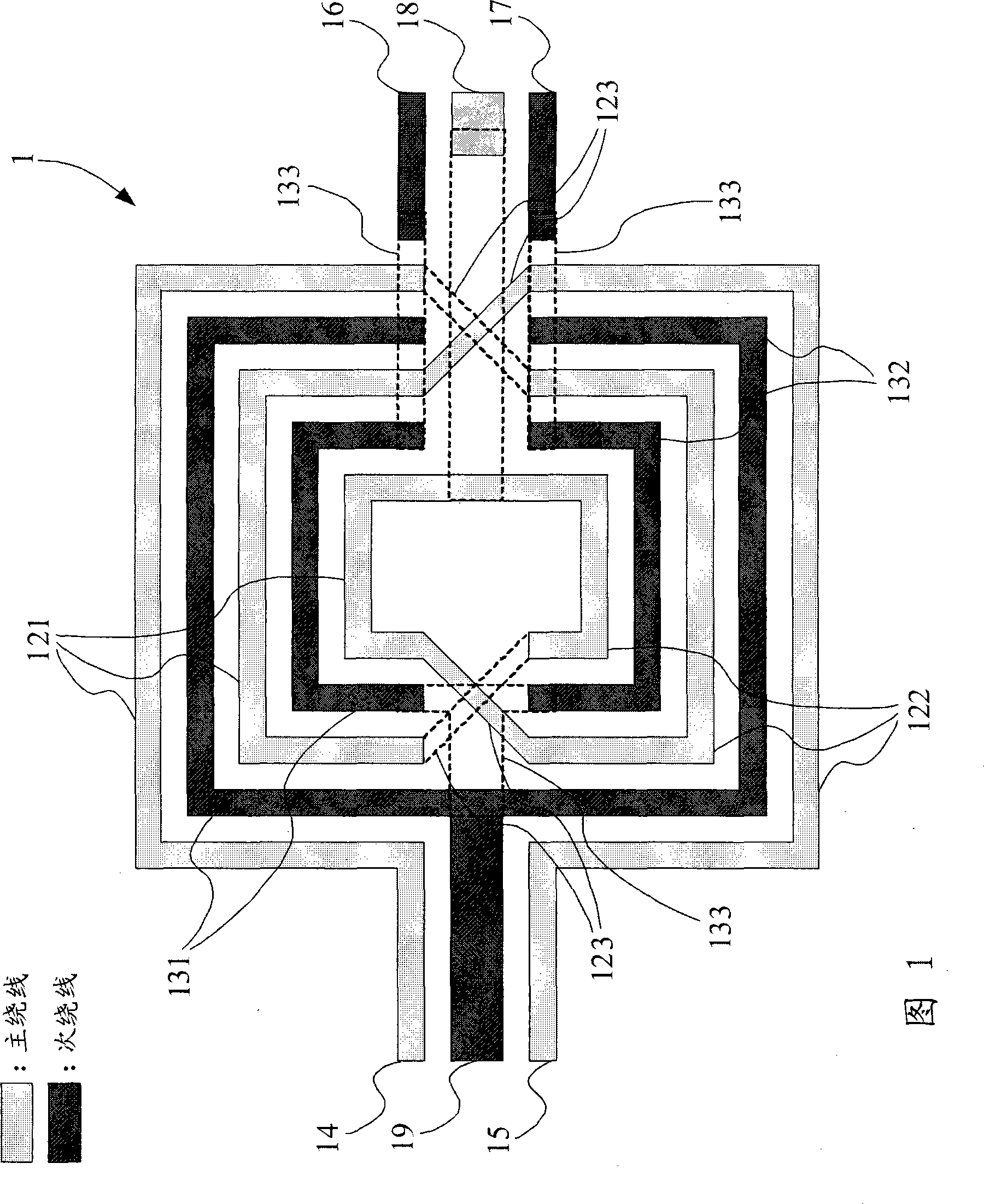

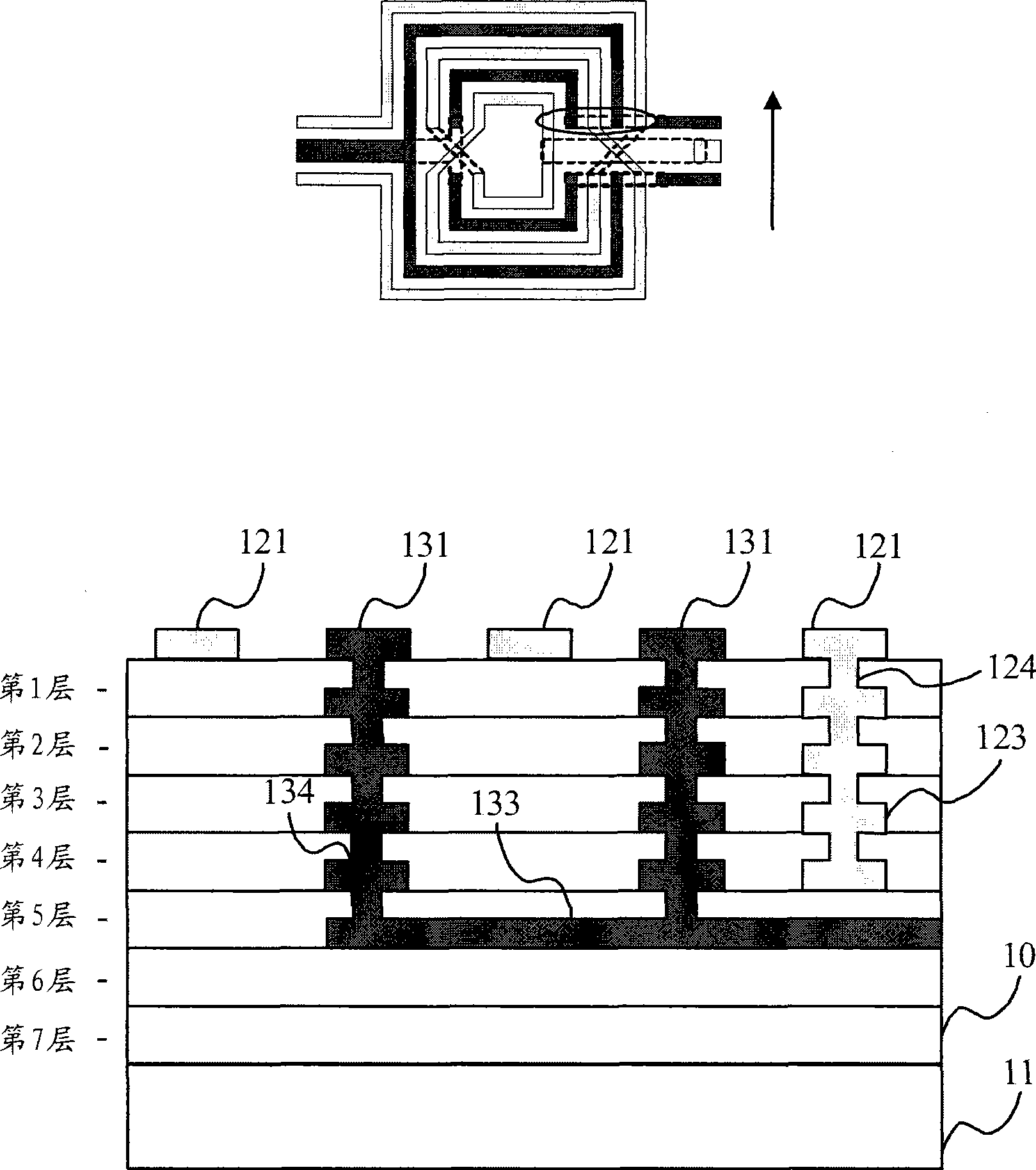

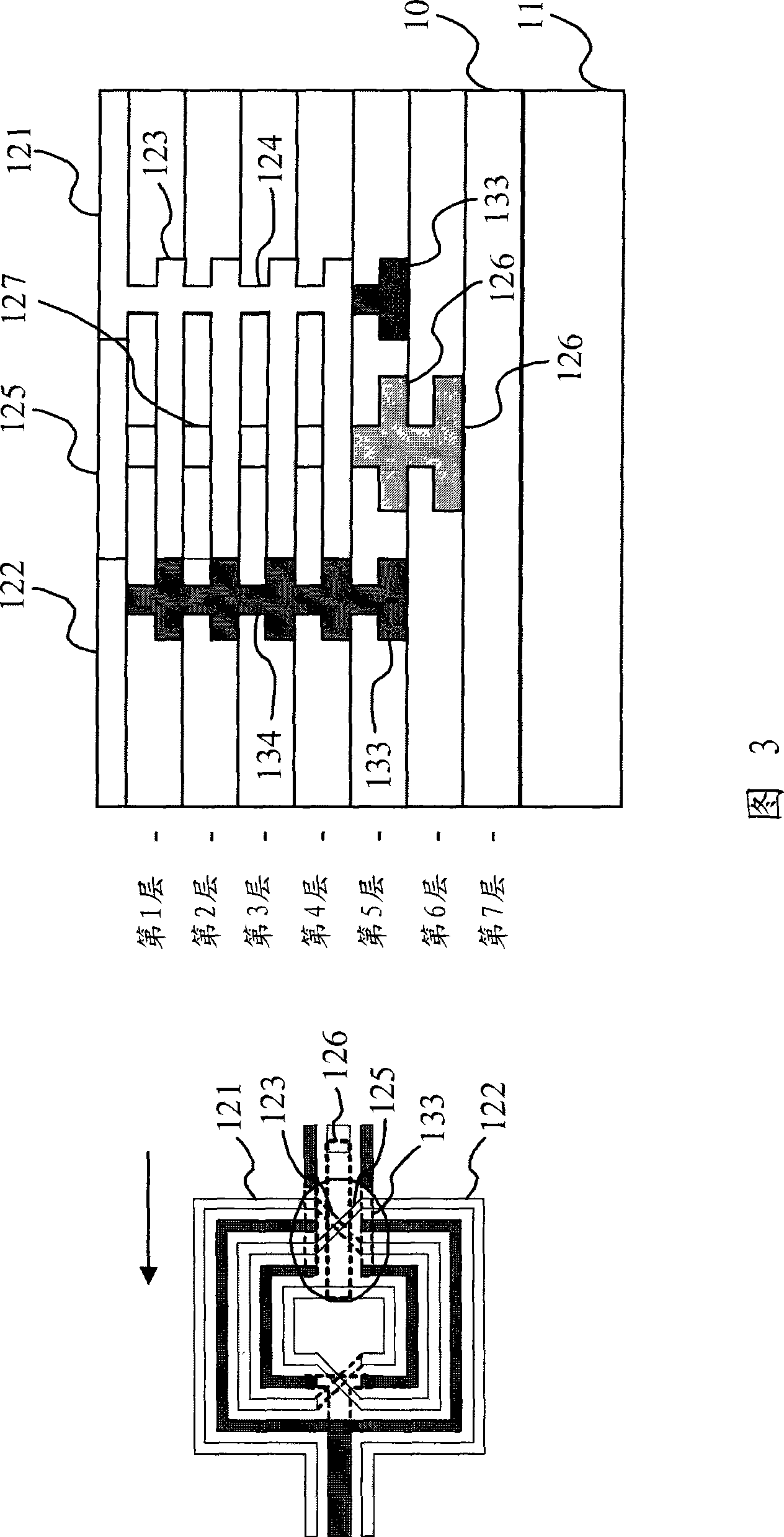

[0028] Please refer to FIGS. 1 to 4 together. FIG. 1 is a front view of a chip-type balun according to a preferred embodiment of the present invention. figure 2 is the first partial side view shown in FIG. 1 . figure 2 Contains a thumbnail of Figure 1 as well as this first partial side view. The first partial side view is a side view of the circled part in the thumbnail along the direction of the arrow in the thumbnail. FIG. 3 is a second partial side view of FIG. 1 . Likewise, FIG. 3 contains the miniature view of FIG. 1 and the second partial side view. The second partial side view is a side view of the circled part in the thumbnail along the direction of the arrow in the thumbnail. FIG. 4 is a third partial side view of FIG. 1 . Likewise, FIG. 4 contains the miniature view of FIG. 1 and the third partial side view. The third partial side view is a side view of the circled part in the thumbnail along the direction of the arrow in the thumbnail. It should be noted that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com