Large amplitude vibration active isolation lever

A technology of isolating rods and large amplitude, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of small expansion range, large bearing capacity, poor bearing capacity, etc., and achieve large vibration isolation range, large bearing capacity, and responsive fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below through specific examples.

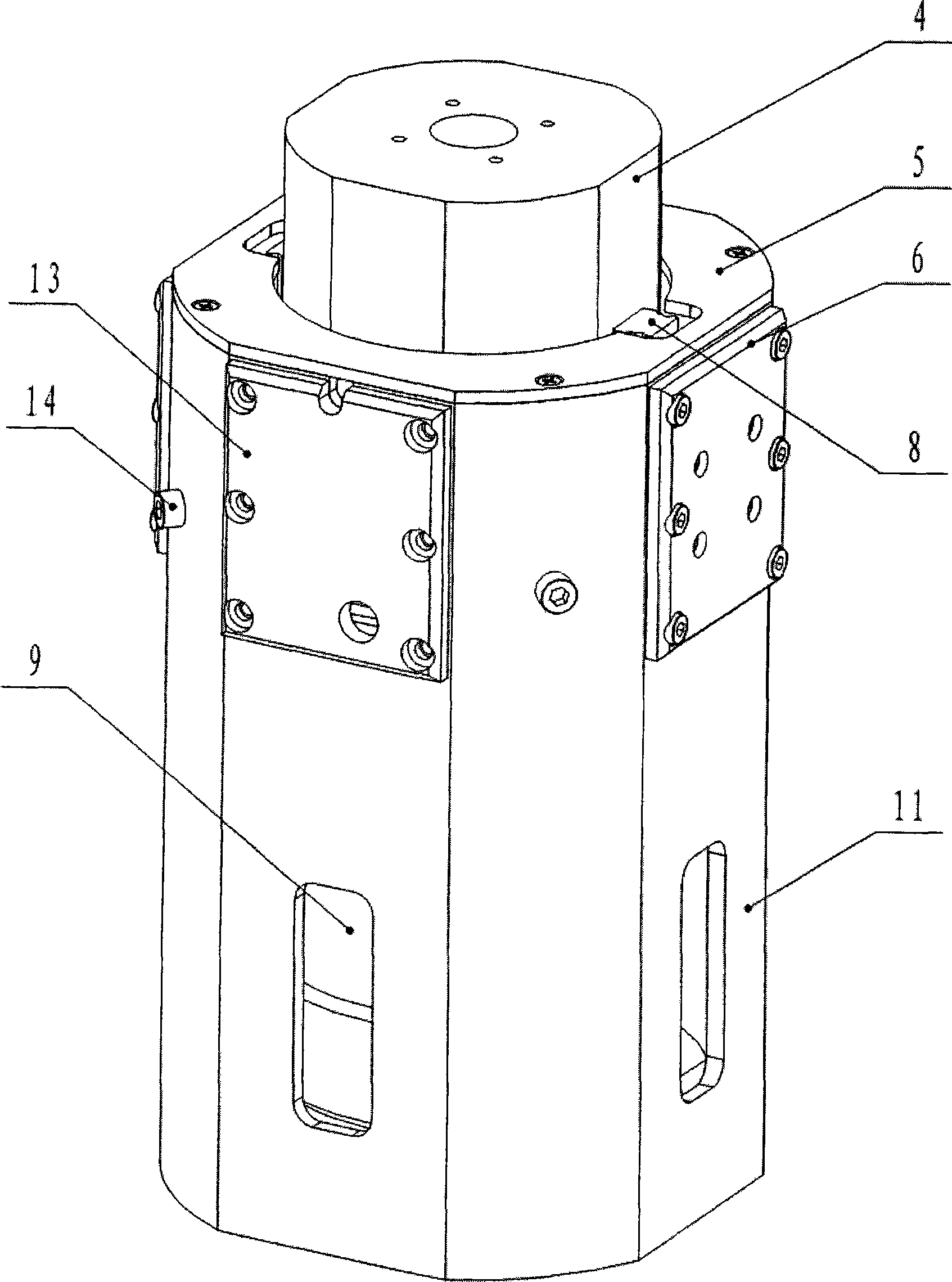

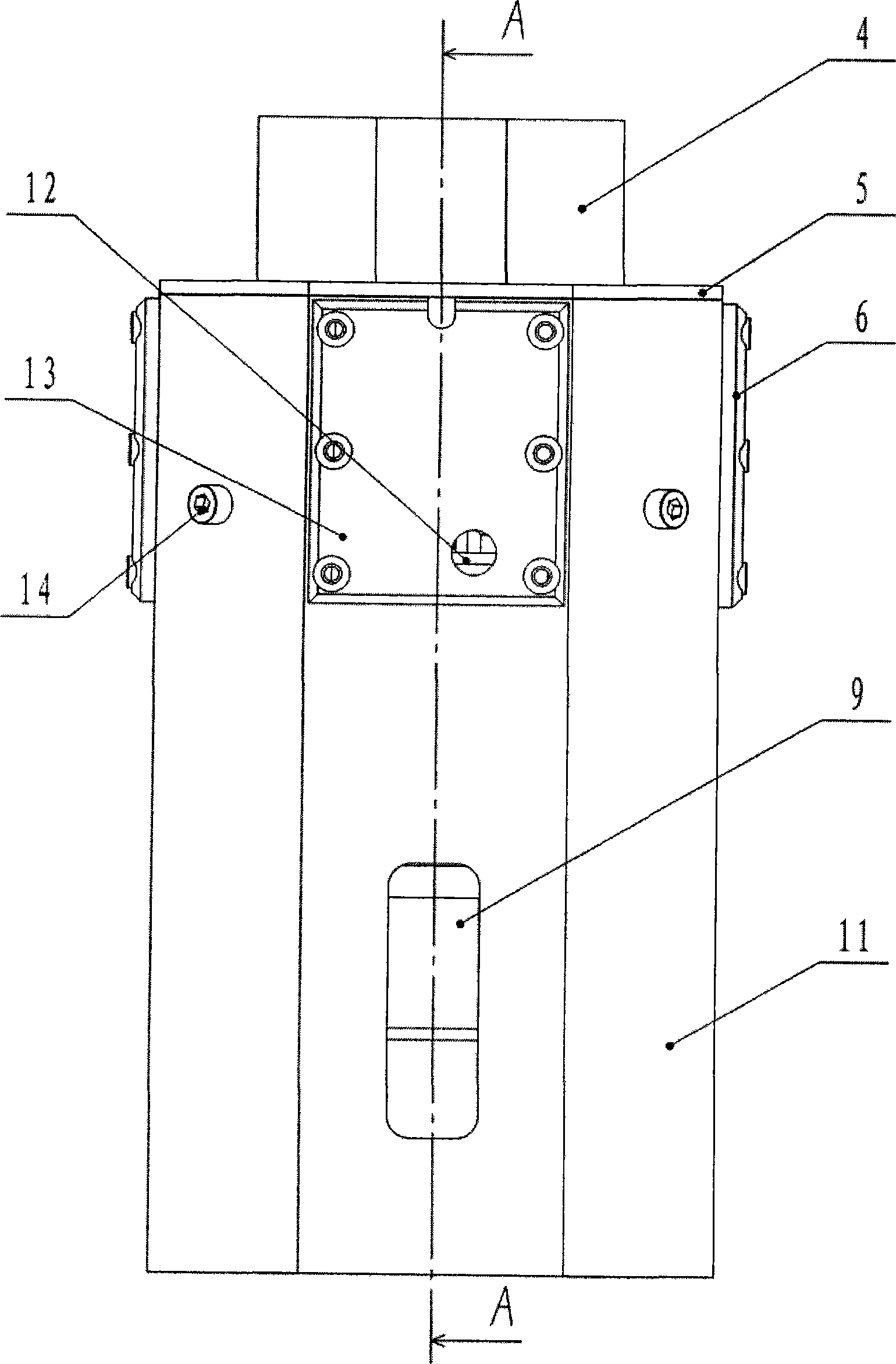

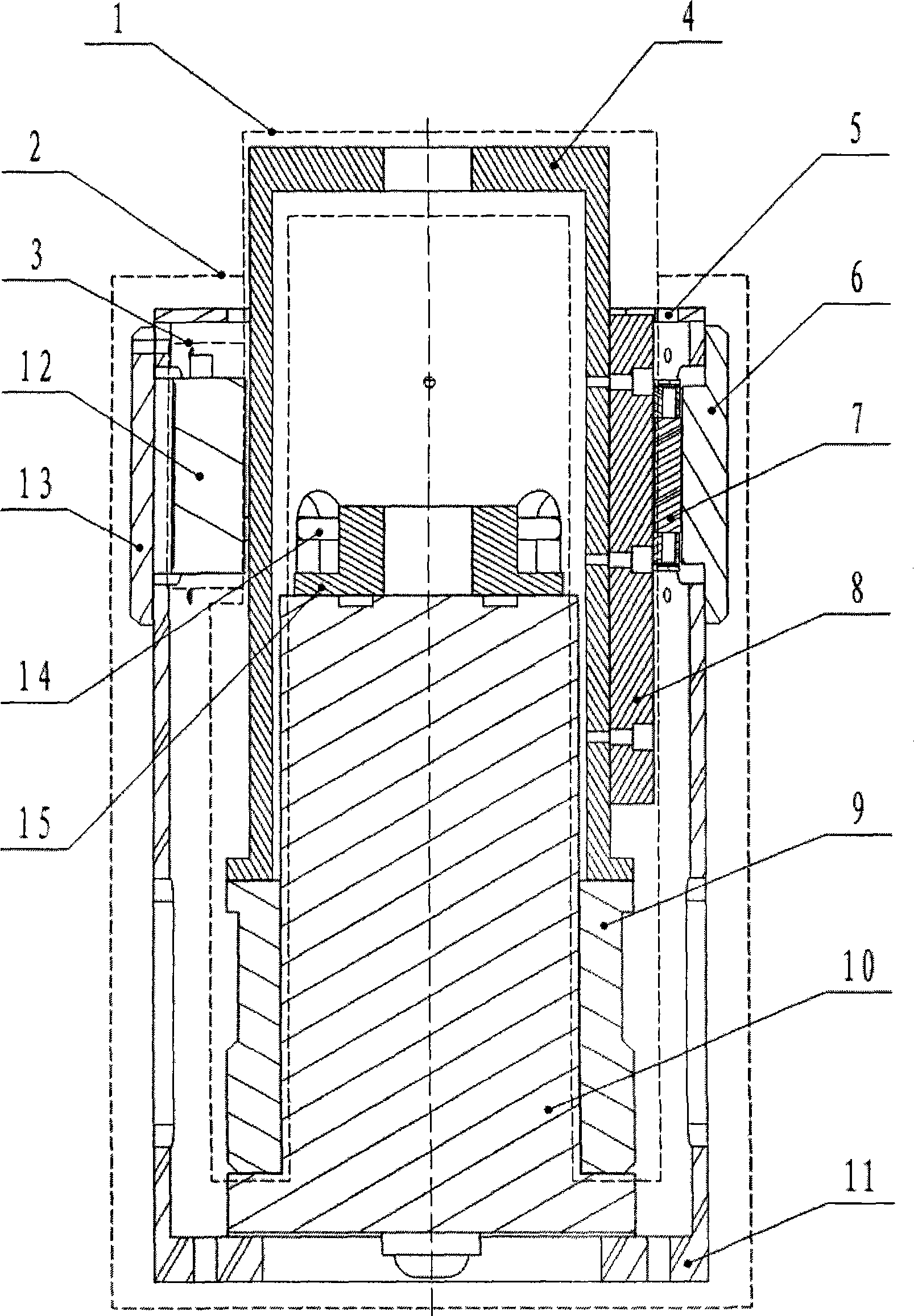

[0030] In this embodiment, the large-amplitude vibration active isolation bar includes three parts: a mover 1 , a stator 2 and a position sensor 3 . The mover 1 is composed of an inner support cylinder 4, a linear guide rail slider 7, a linear guide rail 8, and a motor mover 9; the stator 2 is composed of a dust cover 5, a guide rail fixing plate 6, a motor stator 10, an outer support cylinder 11, and a positioning screw 14 and the top positioning block 15; the position sensor 3 is composed of a grating fixing plate 13 and a grating sensor 12. The mover 1 is on the top and the stator 2 is on the bottom. The mover 1 moves up and down relative to the stator 2 to offset the vibration transmitted by the stator 2 and keep the mover 1 stable. The position sensor 3 is fixed on the stator 2 to detect the stroke of the mover 1 .

[0031] The assembly process of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com