Rolling-mill preloading interference acute blade rolling method and special device thereof

A special equipment and blade technology, which is applied in the field of rolling mill preload interference precision rolling blade method and its special equipment, can solve the problems of unstable preload interference, insufficient adjustment value, quantitative speed adjustment, and inconvenient adjustment. , to achieve the effect of achieving coordination and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

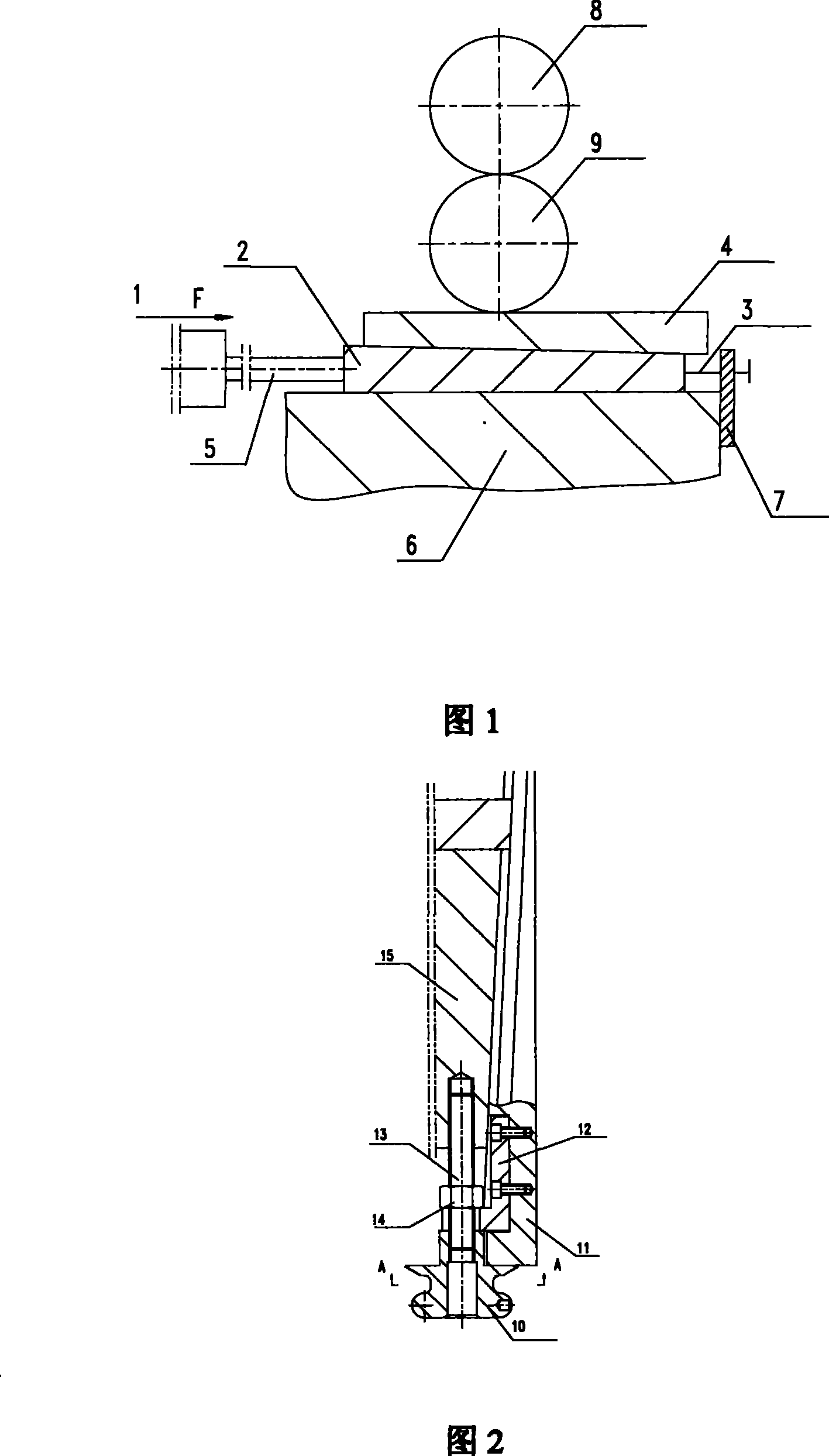

[0034] This embodiment provides a rolling mill preload interference precision rolling blade method, which is characterized in that: the rolling mill is preloaded, and the preload is greater than 1.1 to 1.3 times the resistance generated when the blade is rolled; the resistance generated by the blade meets The following formula:

[0035] F=SE

[0036] F——The resistance produced by the blade

[0037] S——The amount of elastic deformation produced by equipment and forming tools

[0038] E—Elastic modulus of equipment and forming tools.

[0039] In order to reduce or eliminate the influence of the elastic deformation produced by equipment and forming tools on the blade profile, the rolling mill is preloaded, and the equipment and forming tools are elastically deformed by the preload. The preload is greater than that produced when the blade is rolled. During the rolling process, the equipment and forming tools no longer produce elastic deformation, so as to ensure that the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com