Press-type exhaust-heated armrest device

A press-type, exhaust technology, applied in exhaust devices, mufflers, transportation and packaging, etc., can solve the problems of power consumption, consumption, and unfavorable engine self-protection, etc., to achieve convenient operation, controllability, and high application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

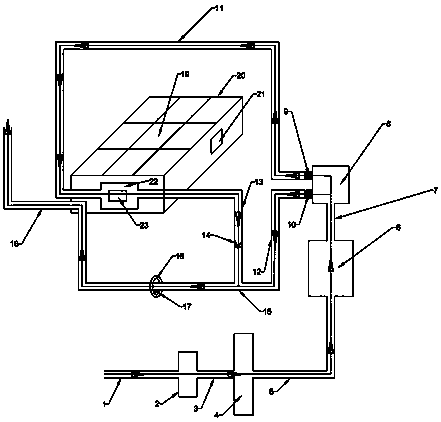

[0012] Such as figure 1 As shown, there are three implementations.

[0013] The exhaust gas pump (2) sucks the exhaust gas into the device through the pipeline No. 1 (1), then the exhaust gas enters the exhaust gas treatment device (4) through the pipeline No. 2 (3), and the purified gas enters the gas collection tank through the pipeline No. 3 (5) (6), the temperature of the gas is detected by the temperature controller (8) through the pipeline No. 4 (7). If the gas temperature reaches 36°C, the gas will enter the pipeline No. 2 (10) through the temperature control switch No. 6 (12) and enter the pipeline 8 No. (15), when the pressure switch (17) on the handrail (16) is pressed, the gas with a temperature of 36°C enters the handrail (16) to achieve the effect of heating, and the gas in the pipe No. 8 (15) passes through the pipe No. 9 (18) is discharged into the car, thereby realizing the improvement of the temperature in the car.

[0014] The exhaust gas pump (2) sucks the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com