Coil ticket printing drum device

A printing cylinder and embossing cylinder technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve problems affecting quality, ghosting, etc., and achieve the effect of ensuring printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

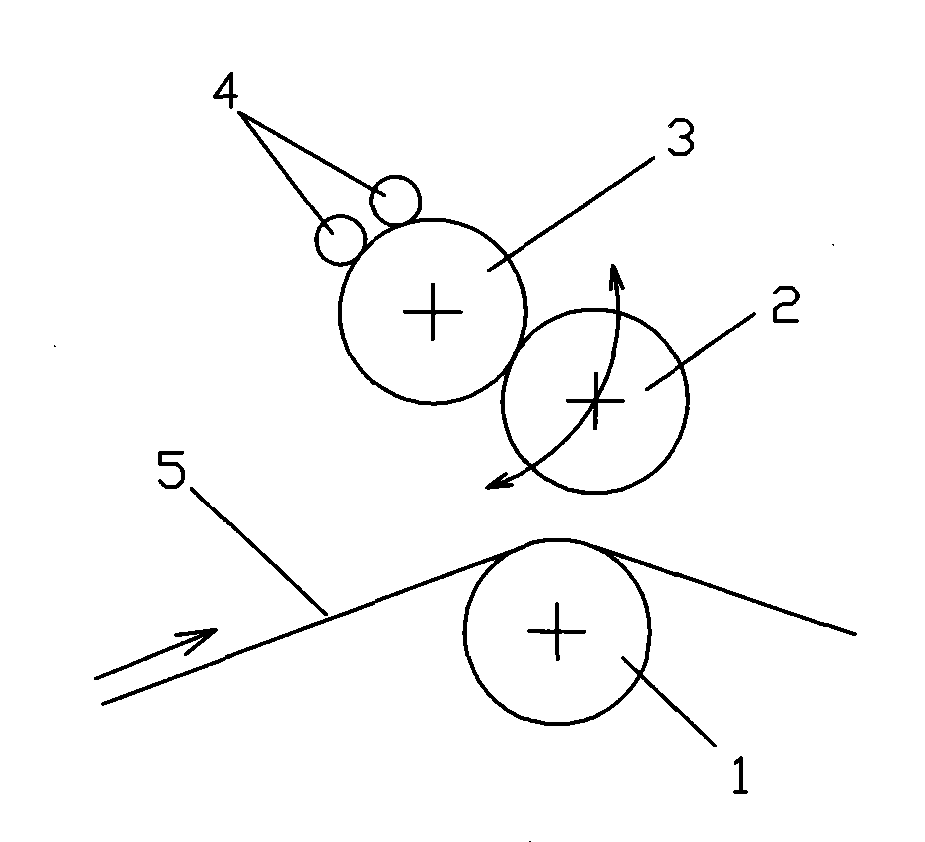

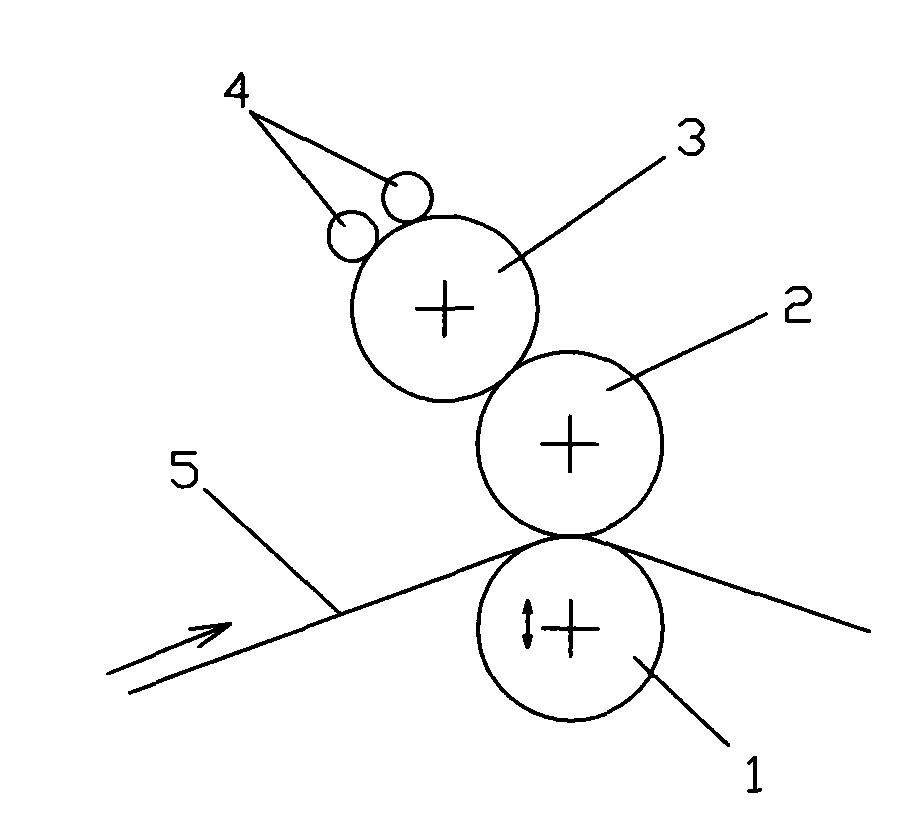

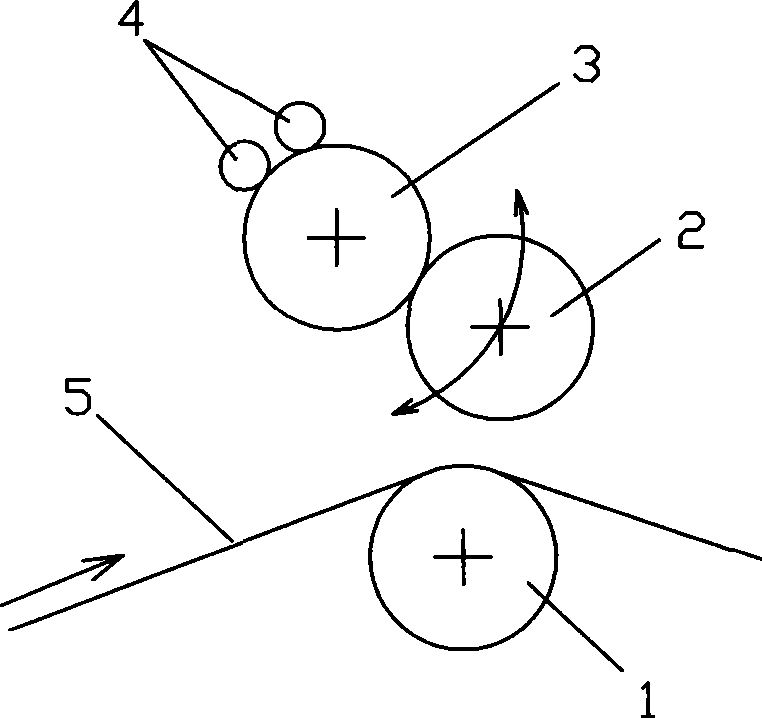

[0009] Such as figure 1 , 2 As shown: an impression cylinder 1, a rubber cylinder 2, a printing plate cylinder 3 and a forme ink roller 4 are installed on the frame. The two ends of the embossing cylinder 1 are equipped with bearings, and the bearing seat bolts matched with the bearings are fixedly installed on the frame, so that the embossing cylinder 1 can only rotate relative to the frame.

[0010] The two ends of the rubber cylinder 2 are axially connected to drive the rubber cylinder 2 to rotate along the center of the printing plate cylinder 3. The specific structure is as follows: the two ends of the rubber cylinder 2 are fitted with eccentric sleeves, and the eccentric sleeve and the frame are connected by rotation , so that the eccentric sleeve can rotate relative to the frame. The eccentric sleeve is connected with a push rod, and the push rod is connected with a piston rod matched with a cylinder installed on the frame, and the cylinder is connected with the pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com