Drawing detwister in back area for spinning frame

A spinning frame and drafting technology, which is applied to spinning frames, drafting equipment, and untwisting devices for processing textile materials, etc., can solve the problems of disordered fibers of roving sliver, affecting spinning quality, etc., and achieves low cost and reliable work. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

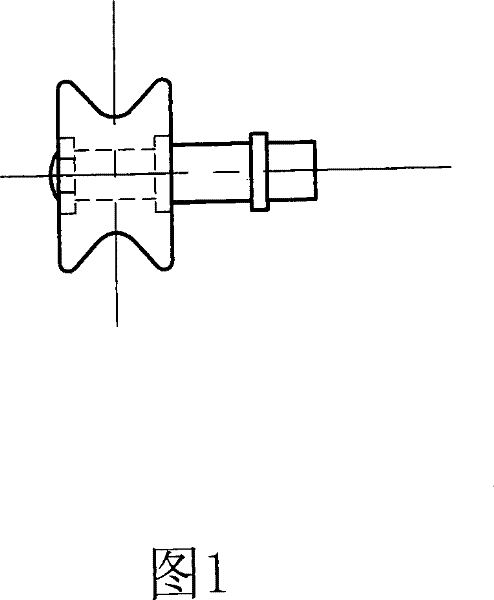

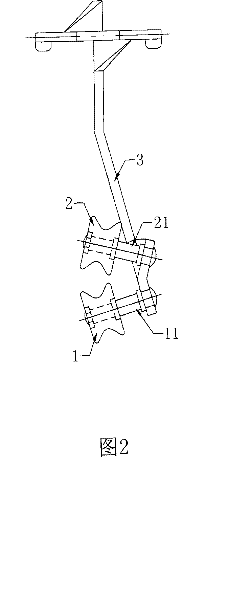

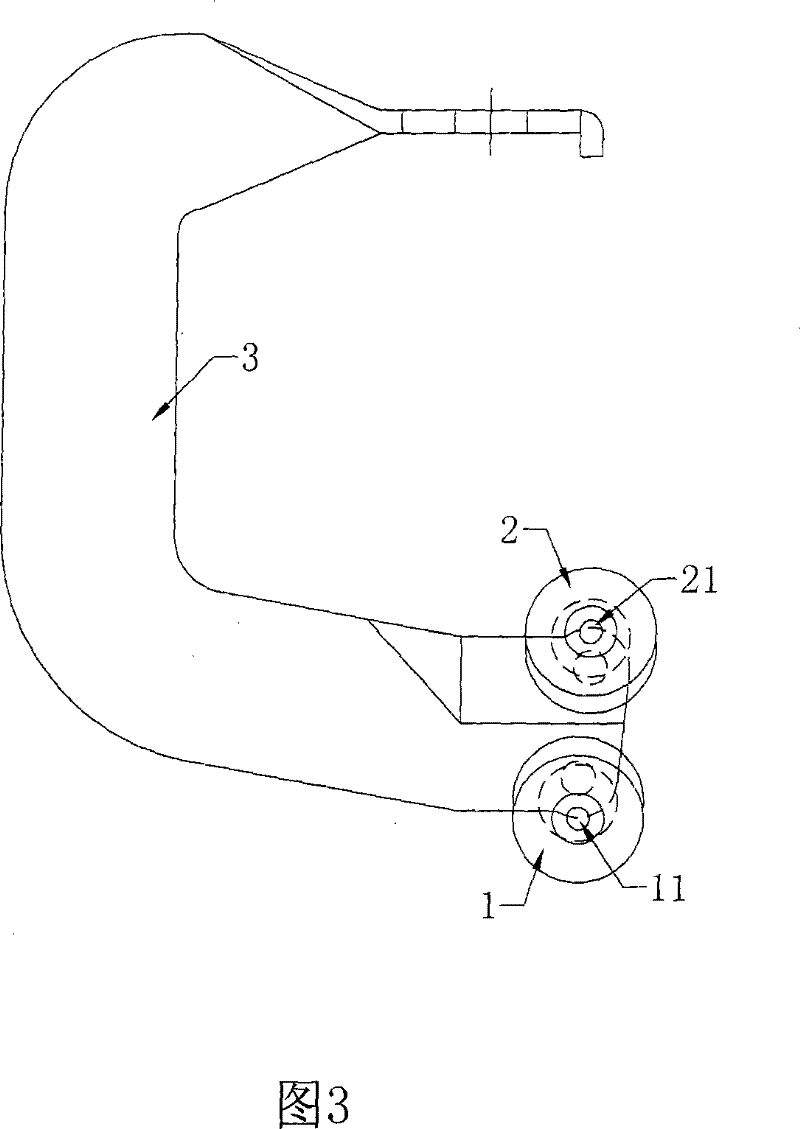

[0020] Embodiment: a drafting and untwisting device for the rear area of a spinning frame, which is provided with a bracket and at least one roller, the roller is movably sleeved on the roller shaft, the roller shaft is fixed on the bracket, and the roller peripheral surface is provided with There are trumpet-shaped grooves for the roving strands to pass through, and there is a certain angle between the direction of the circular rotation of the horn-shaped grooves and the direction of the roving strands.

[0021] Calculated according to the acute angle direction, the included angle is between 10 degrees and 30 degrees.

[0022] There are first and second two rollers, and the two rollers are respectively movably sleeved on the two roller shafts, and the two roller shafts are respectively fixed on the same side of the bracket, and the second included angle between the two roller shafts is 15 degrees to 45 degrees between,

[0023] The groove is V-shaped.

[0024] The diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com