Ignition switch with gearing construction

An ignition switch and gear transmission technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems affecting the interior space arrangement of the car and the aesthetics of the car console, so as to save length and space, make the space layout more flexible, shorten The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

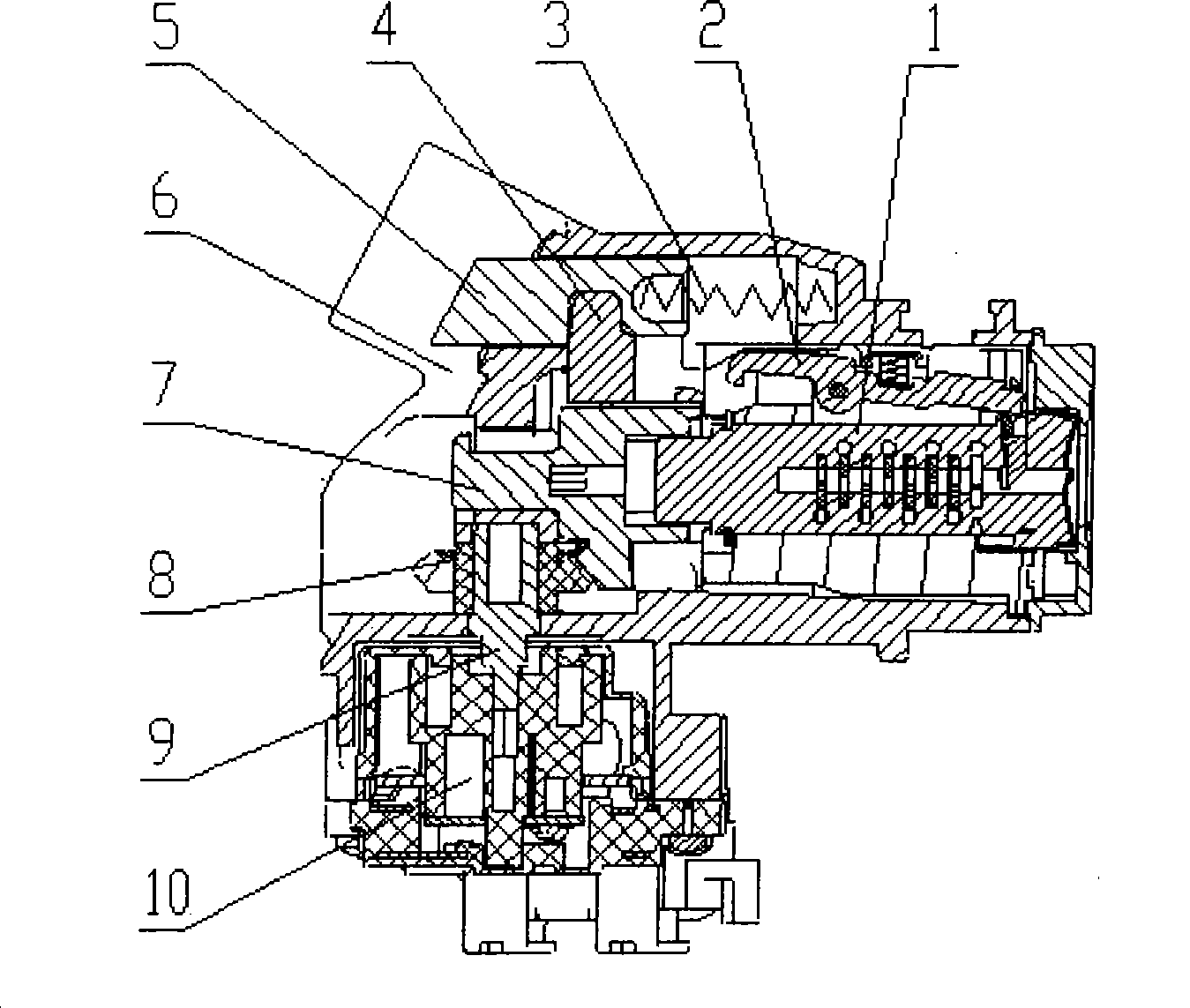

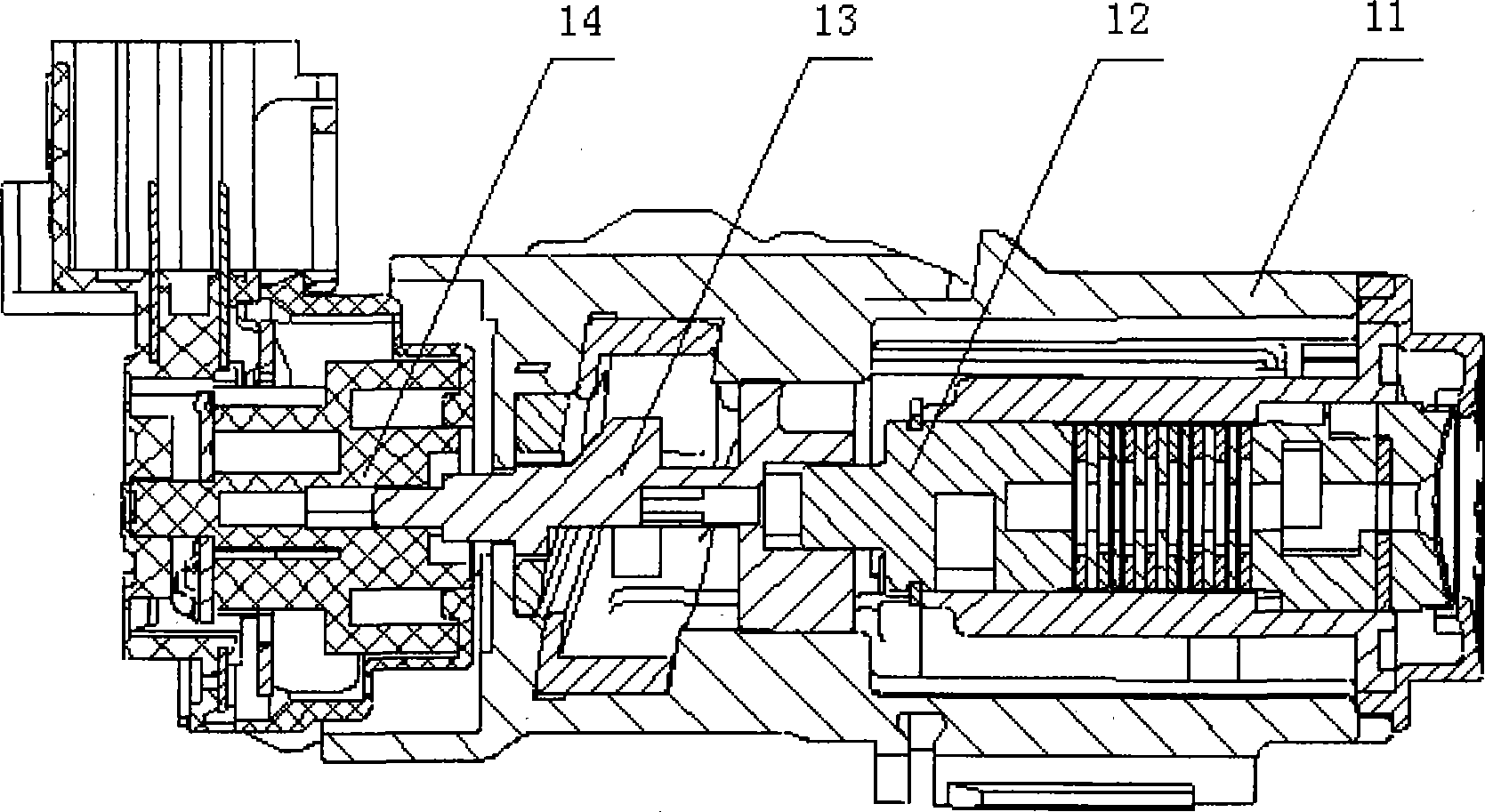

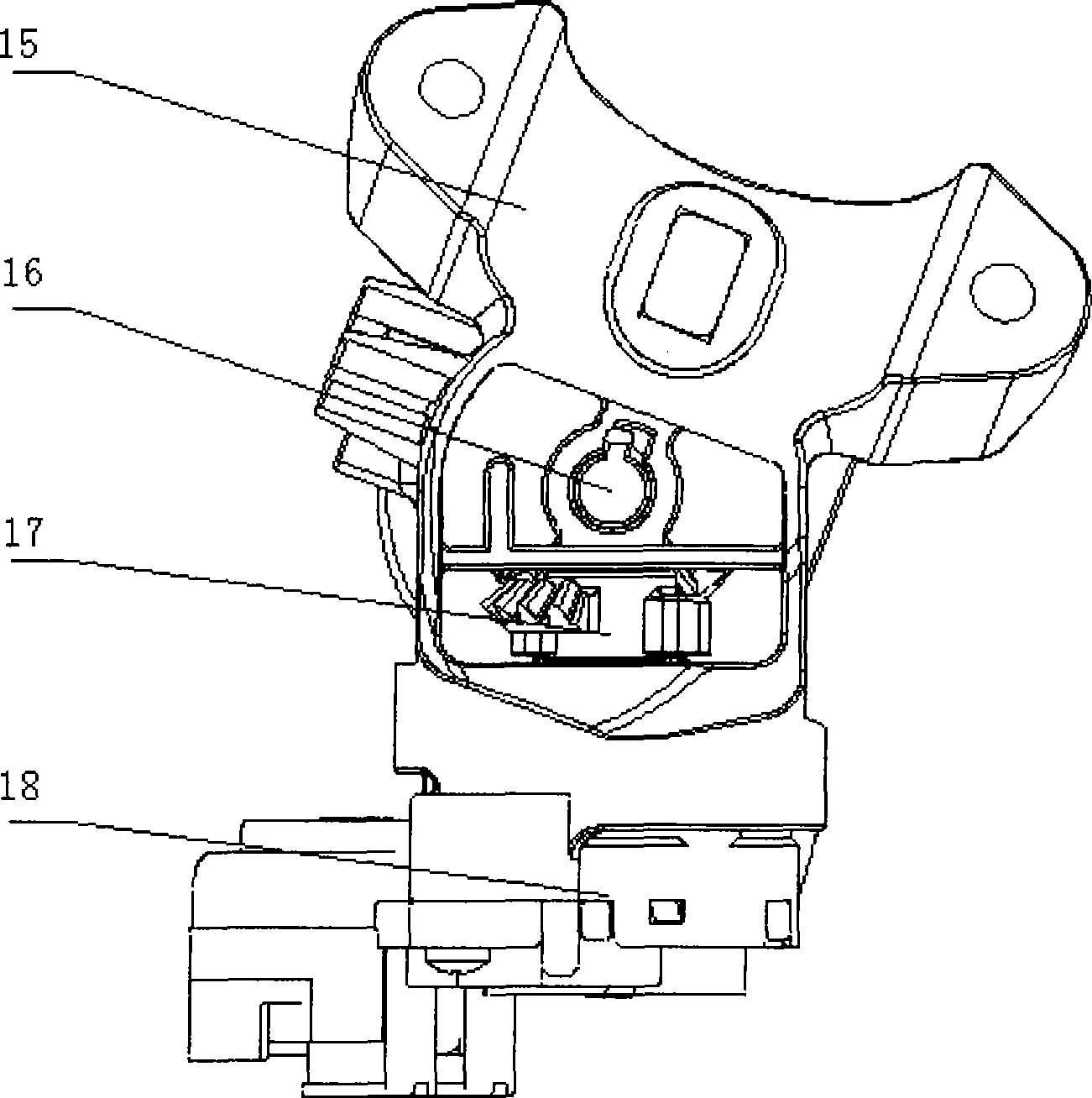

[0014] Ignition switch with gear transmission structure, including ignition lock and ignition rear cover assembly 10: there is a lock cylinder 1 at the front end of the ignition lock, a shaft is installed in the center of the ignition lock, the lock cylinder 1 is fixedly connected with the shaft, and there is a driving gear 7 on the shaft. The gear 7 is located at the rear end of the ignition lock; there is also a driven shaft 9 in the center of the ignition rear cover assembly, and the driven shaft 9 has a driven gear 8 near the position of the ignition lock. The driving gear 6 and the driven gear 8 are The bevel gears mesh with each other. The included angle between the shaft and the driven shaft 8 is 90-135 degrees.

[0015] When working, insert the key, turn the ignition lock cylinder, and drive the main gear to rotate. The rotation of the main gear will transmit the transmission force to the paired auxiliary gear. After the auxiliary gear rotates, it will drive the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com