Arc-suppressing load switch

A load switch and arc extinguishing technology, which is applied in electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as limited arc extinguishing capacity and arc extinguishing failure, and achieve reduced damage, reduced installation surface, and torque small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

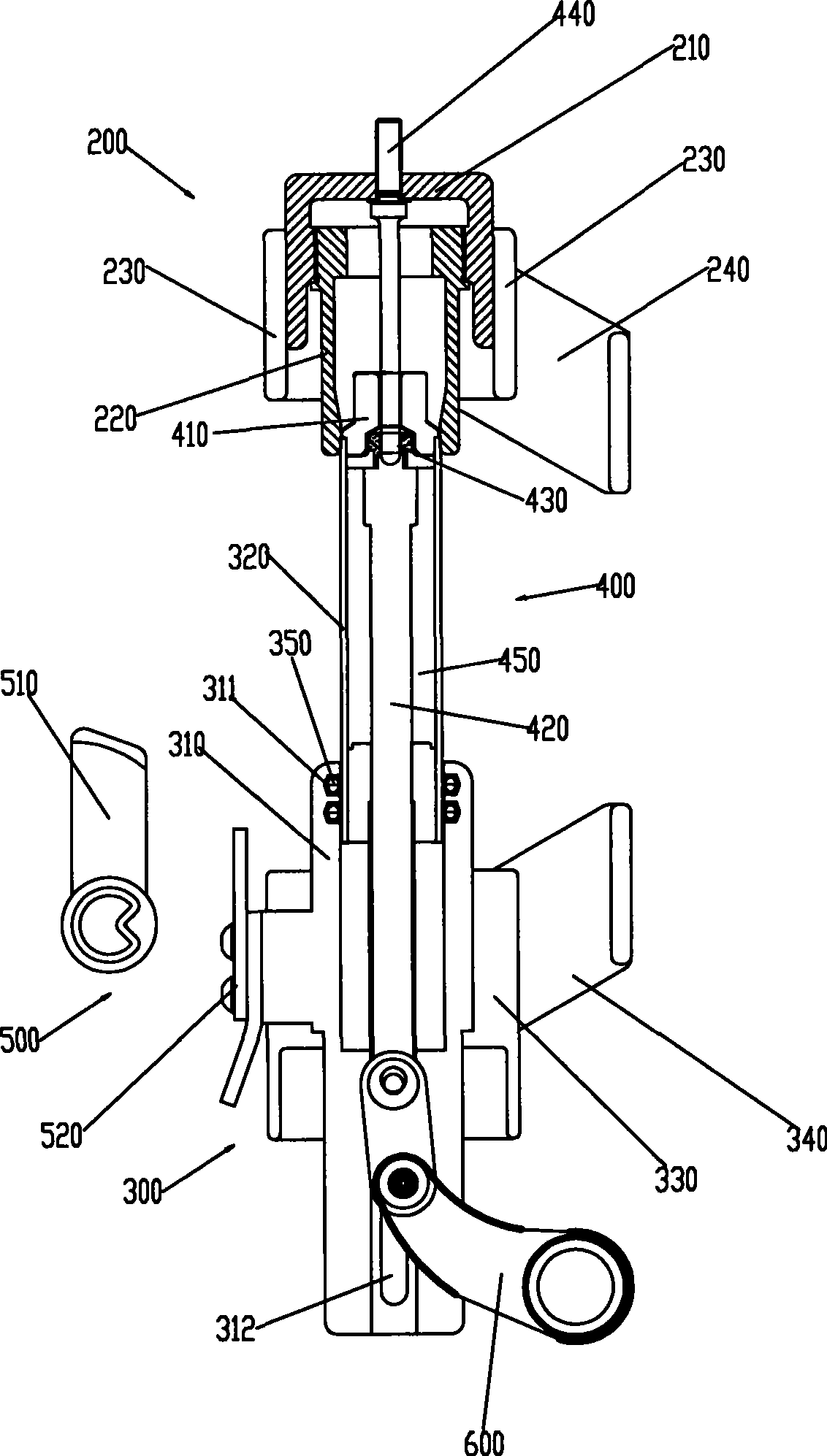

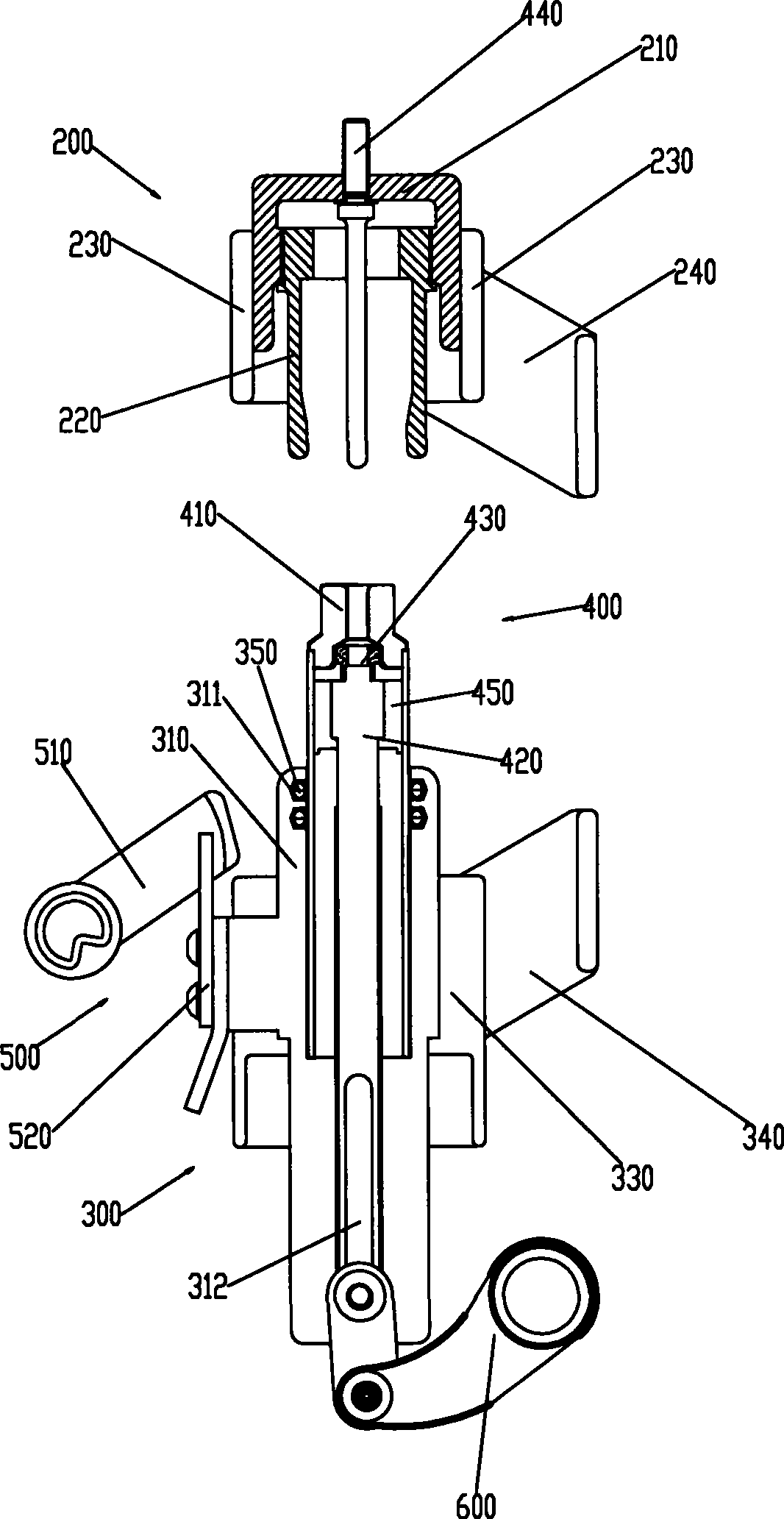

[0030] Please check figure 1 with figure 2 , Arc extinguishing load switch, which includes a base, an upper pole assembly 200, a lower pole assembly 300, an arc extinguishing assembly 400, a grounding switch 500 and an operating mechanism 600.

[0031] The base includes a shell, which is closed and filled with SF6 gas. An upper support beam and a lower support beam are fixed in the shell, the upper support beam and the lower support beam are both C-shaped with openings facing outwards, and the upper support beam and the lower support beam are fixed horizontally at intervals up and down.

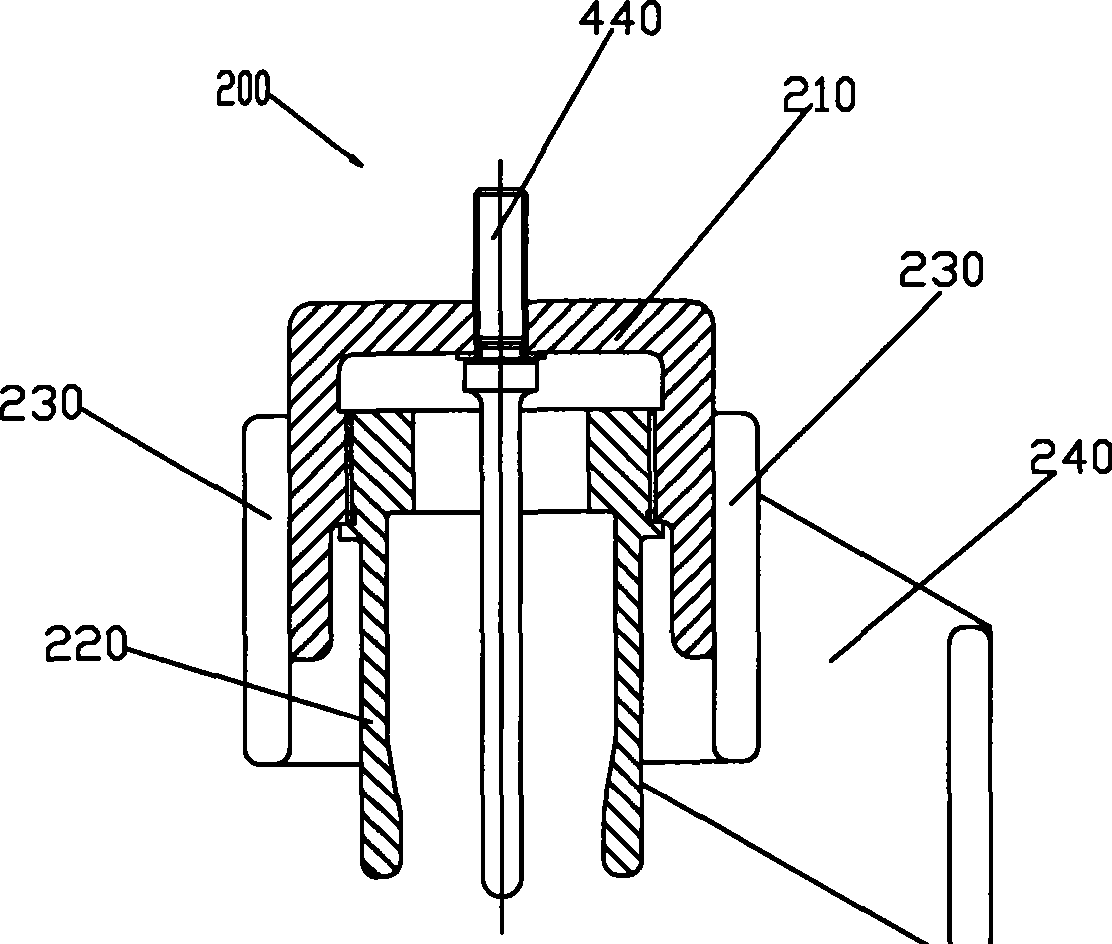

[0032] Please check figure 1 , figure 2 with image 3 , the upper pole assembly 200 includes an upper conductive seat 210 , a static contact 220 and an upper pole 230 . The static contact 220 includes a conductive circular sleeve, and a plurality of notches are evenly spaced on the bottom ring surface of the circular sleeve, which does not penetrate through the axial direction but pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com