Self-excitation type speed inhibitor having water cooling system

A water cooling system, self-excited technology, applied in asynchronous induction clutch/brake, shape/style/structure of winding conductor, magnetic circuit shape/style/structure, etc., can solve the cooling bottleneck of self-excited retarder, prolong the duration Braking time and other issues, to achieve the effect of simple structure, increased braking torque and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

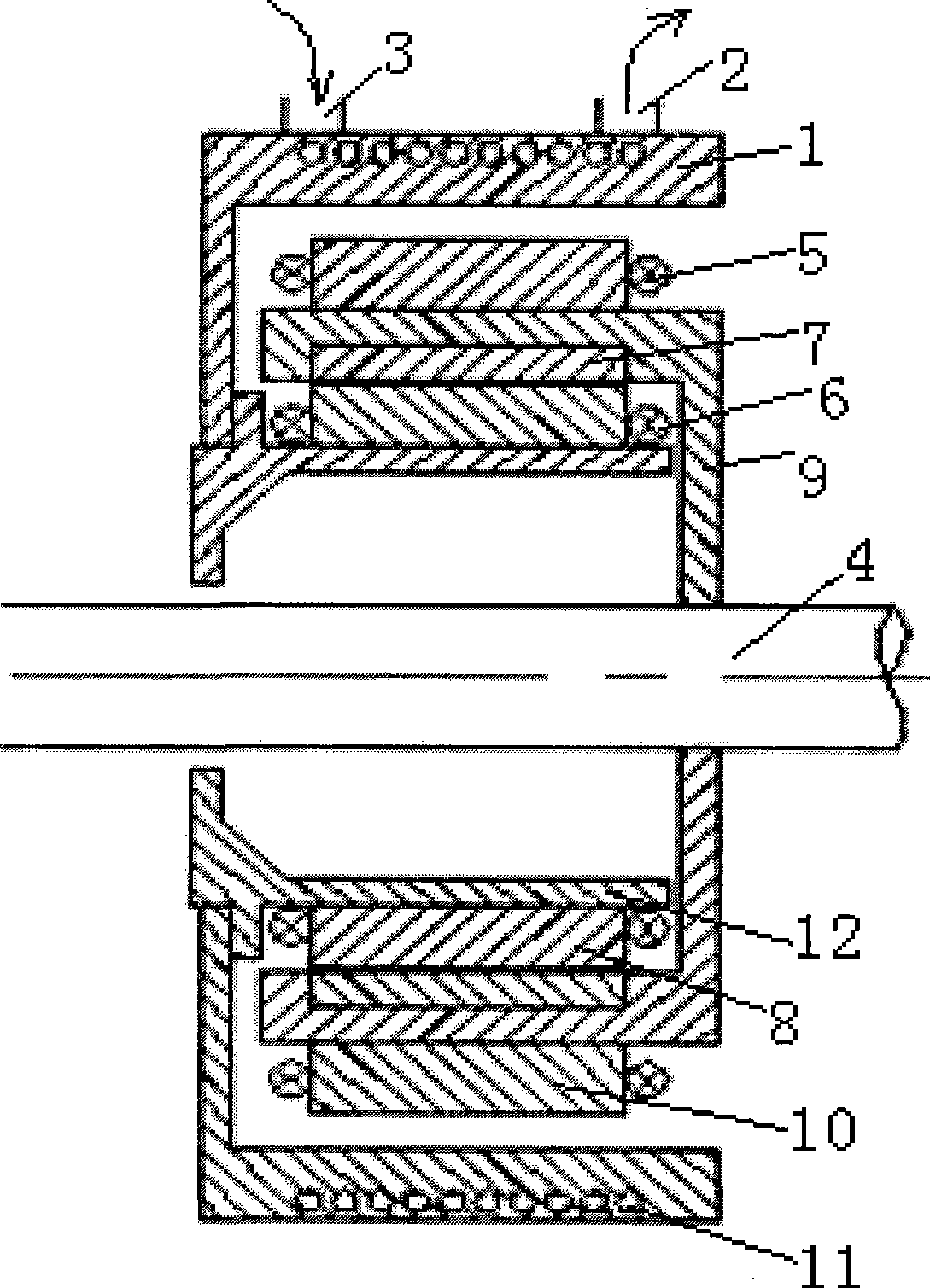

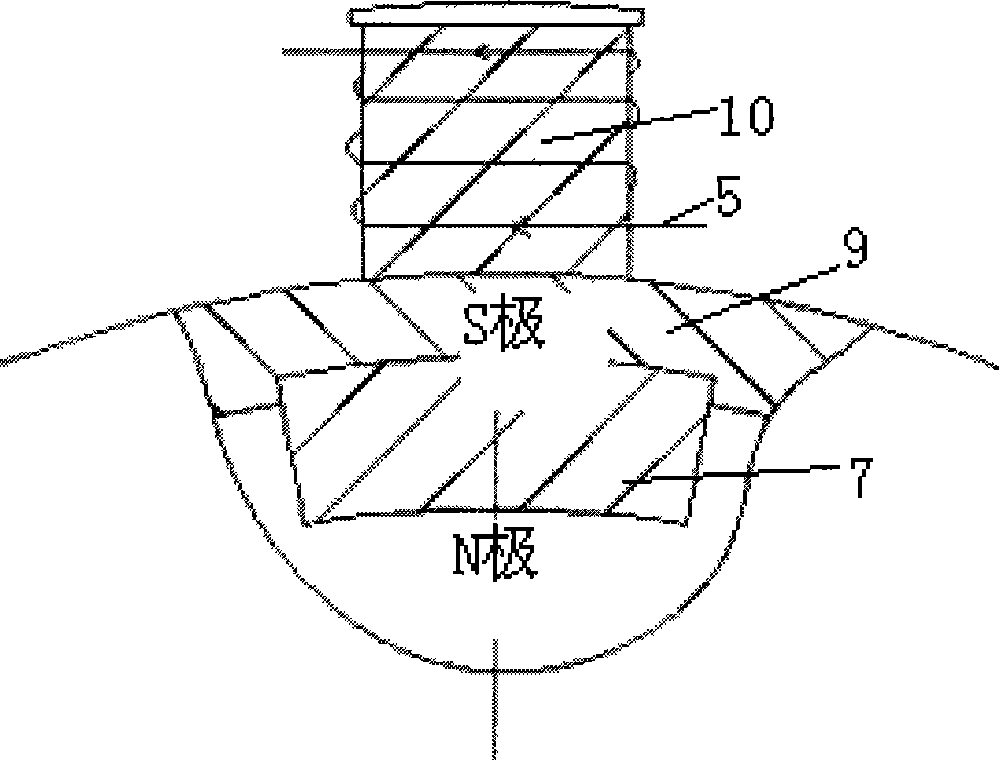

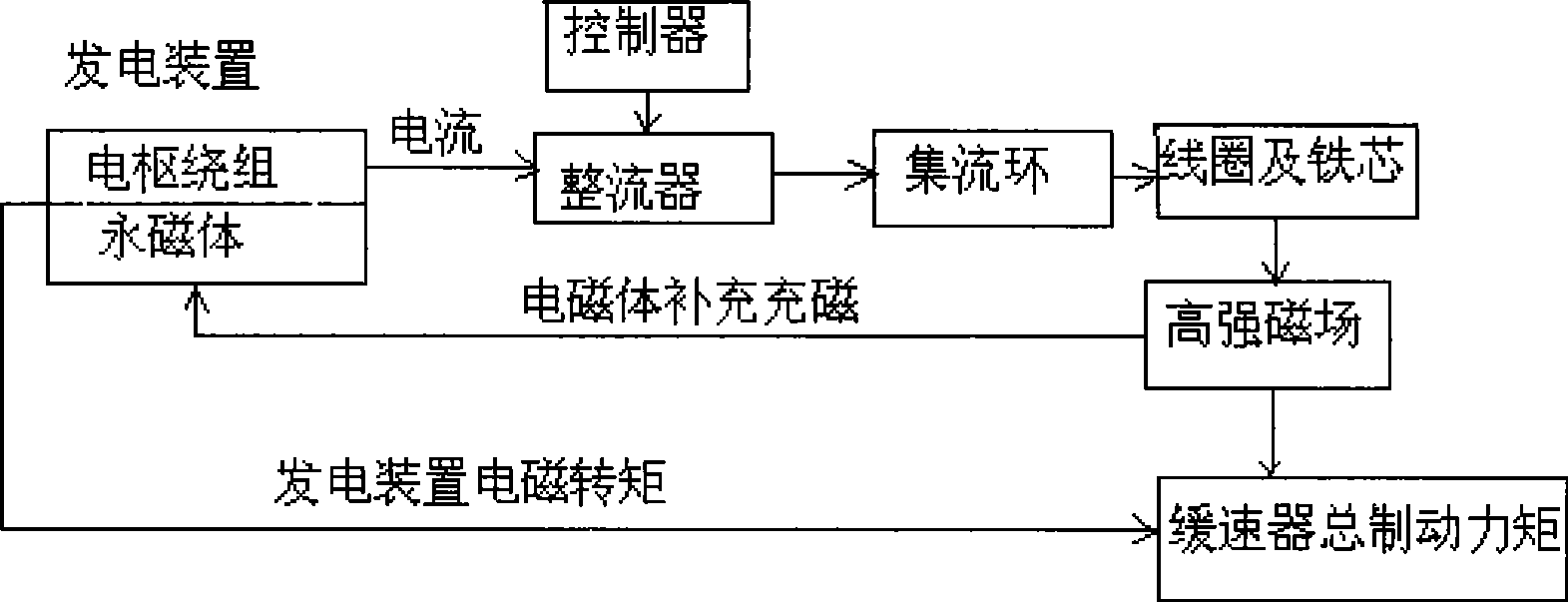

[0012] like figure 1 , including the eddy current induction cylinder stator 1 of the outer layer retarder radially, the rotor 9, the rotor permanent magnet pole 7 of the inner generator device and the generator armature 8, the rotor 9 and the drive shaft 4 are fixedly connected by bolts. The stator 1 is located on the outer layer of the rotor 9, and the rotor 9 is composed of the excitation coil 5 and the iron core 10 of the retarder and the permanent magnet pole 7 of the power generation device. The iron core 10 and its excitation coil 5 are installed on the outside of the rotor 9, the iron core 10 and the rotor 9 are connected and installed by screws, the permanent magnetic poles 7 of the power generation device are installed on the inside of the rotor 9, and the magnetic poles 7 are arranged in N-S-N-S... figure 2 shown. The magnetic pole directions of the exciting coil 5 and the iron core 10 and the permanent magnet pole 7 are the same. The stator 1 is composed of a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com