PET flame-proof monofilament

A technology of monofilament and oil-resistant oil, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, melt spinning, etc. Insufficient smoothness and other problems, to achieve the effect of brighter color, excellent flame retardant performance, and silky smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

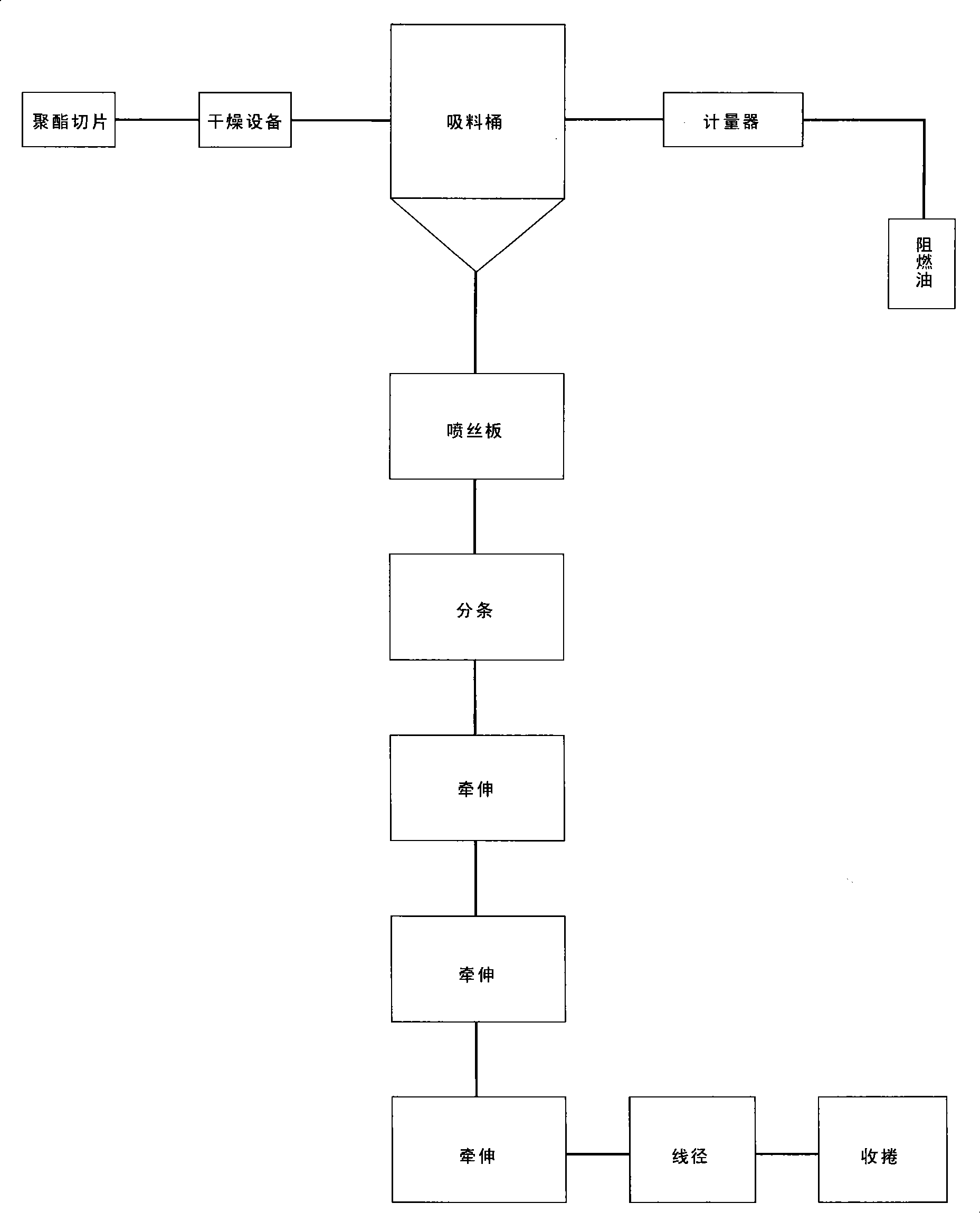

[0010] like figure 1 As shown in the above, a method of manufacturing PET flame-retardant monofilaments is first to put polyester chips into drying equipment such as a dryer to dry, and then the dried polyester chips are mixed with retardant oil and color masterbatch into a suction bucket to melt. The retardant oil container of the present invention is connected with a gauge and then connected with a suction barrel, which can accurately ensure the added amount of retardant oil. The melted material mixed and melted is divided into strips through the spinneret, and the wire is drawn and extruded repeatedly to obtain the required wire diameter before winding.

[0011] The percentage by weight of each component of the PET flame-retardant monofilament of the invention is: 85-95% of polyester chip; 12-4.6% of flame-retardant oil; 3-0.4% of color masterbatch. The optimum weight percentage of each component of PET flame-retardant monofilament is: polyester chip 91%; retardant oil 8%;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com