Overload prevention device for construction machine

A construction machinery and anti-overload technology, applied in construction, mechanical equipment, control devices, etc., can solve the problems of increased fuel injection volume, engine loading and deceleration, etc., to eliminate engine loading and deceleration, reduce fuel consumption, and improve operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, an overload prevention device for a construction machine according to an embodiment of the present invention will be described with reference to the accompanying drawings.

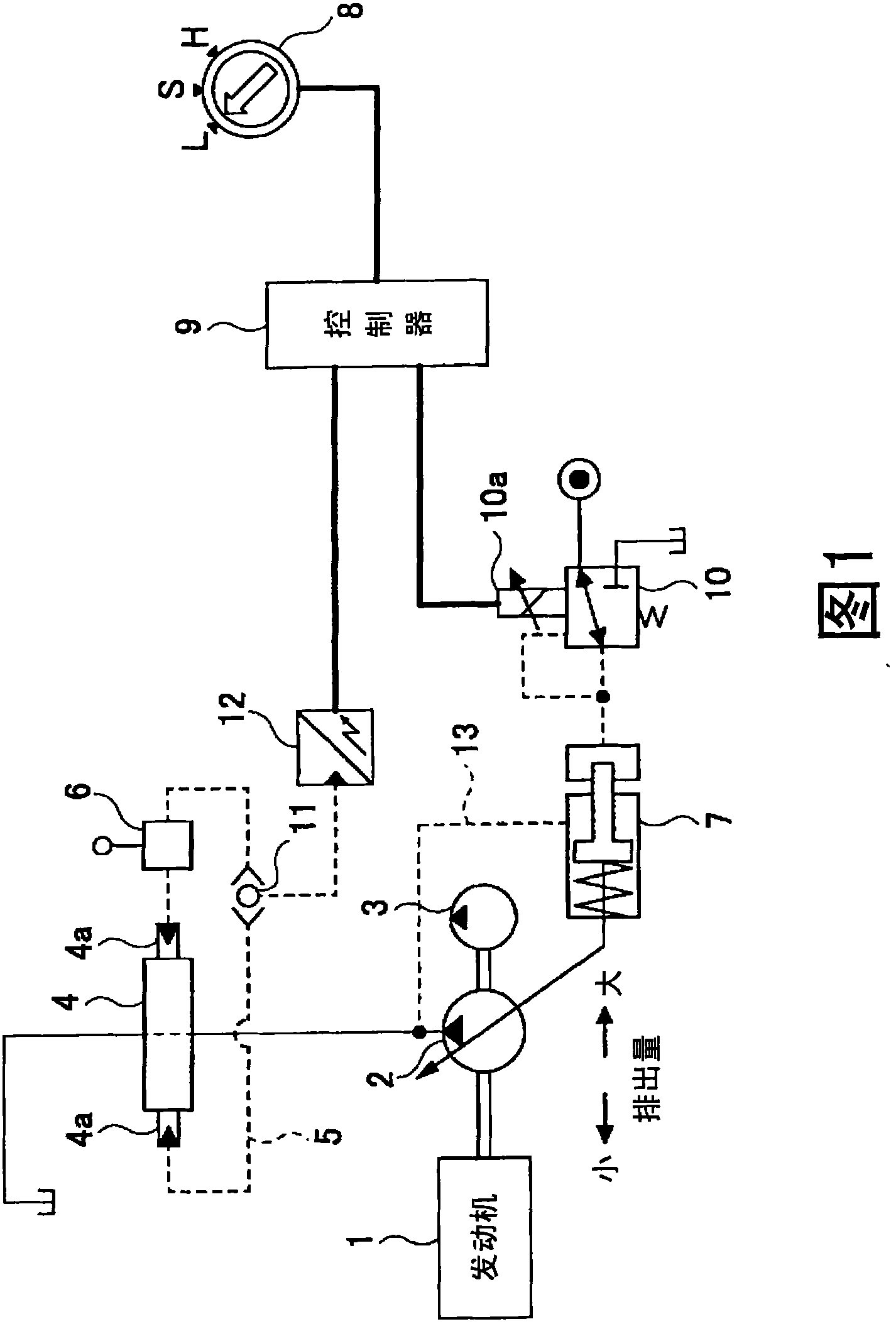

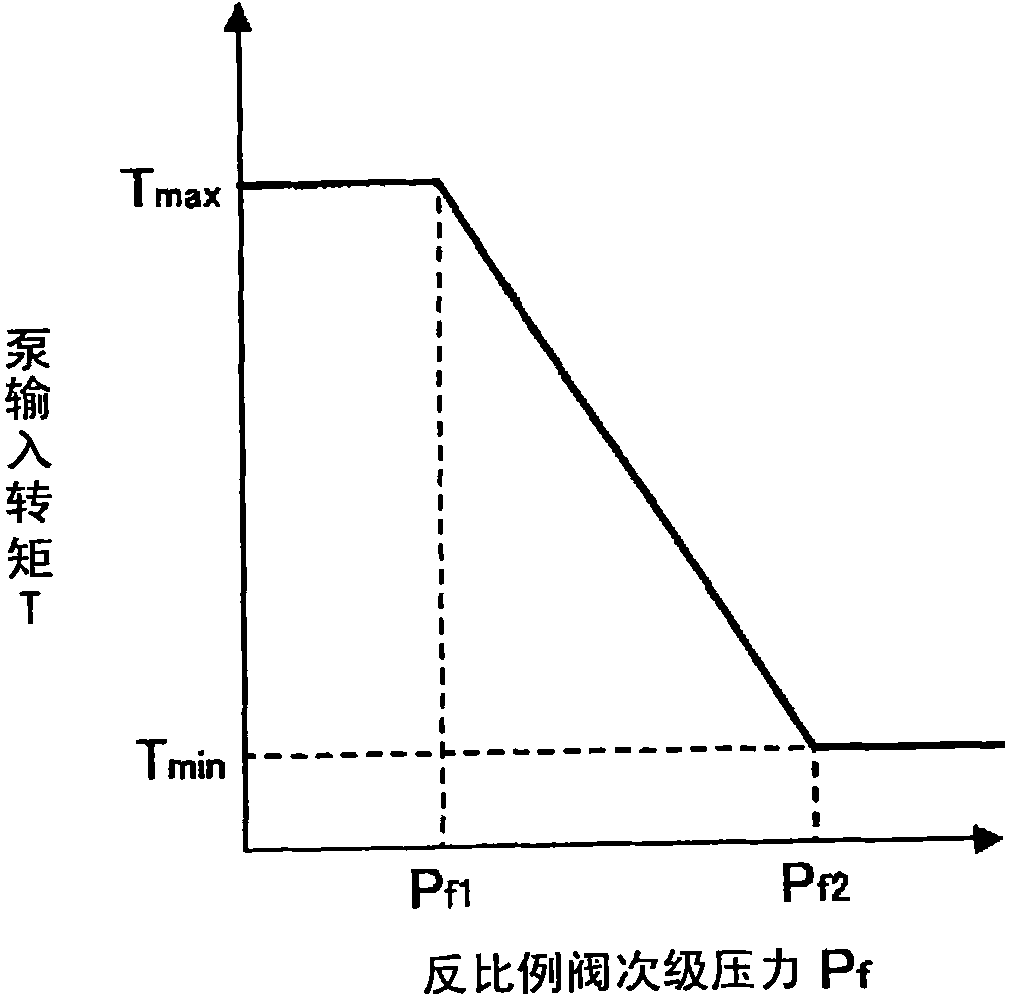

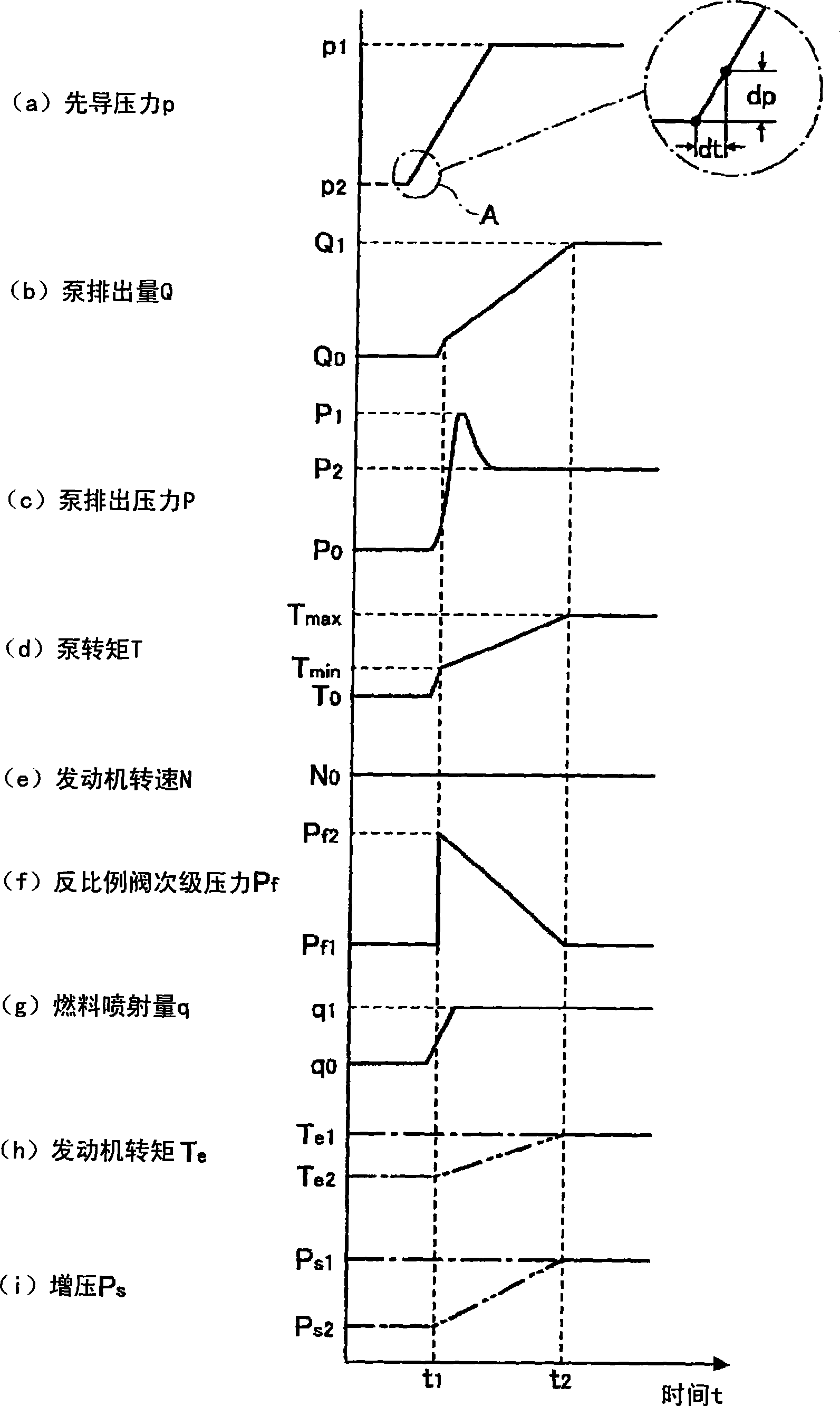

[0040] figure 1 It is a figure which shows the hydraulic circuit of the overload prevention device of the construction machine which concerns on one Embodiment of this invention. figure 2 yes means figure 1 The torque characteristic diagram of the relationship between the secondary pressure of the electromagnetic inverse proportional valve and the pump input torque of the embodiment. image 3 yes means figure 1 The timing diagram of each characteristic in the embodiment. In addition, in figure 1 Neutral to and Figure 7 The structural elements that are the same as the shown structural elements are marked with the same symbols, and repeated explanations are omitted.

[0041] As described above, in order to prevent engine load deceleration from occurring when the discharge press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com