Method of compensating wavelength dependence of birefringence of optical part, optical part, and display obtained with these

An optical component, dependent technology, used in optical components, optics, nonlinear optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0244] This embodiment relates to a method of correcting the wavelength dependence of birefringence. Specifically, the wavelength dependence of the birefringence of an optical component (optical element) (B) is corrected using a film (a) containing a (co)polymer (α) using At least one olefin selected from 4-methyl-1-pentene, 3-methyl-1-pentene and 3-methyl-1-butene is obtained as a (co)polymerization component.

[0245] First, the film (a), its production method, and the (co)polymer (α) will be described below.

[0246] (film (a))

[0247] The film (a) used in the above-mentioned correcting method contains a specific (co)polymer (α) selected from the group consisting of 4-methyl-1-pentene, 3-methyl- At least one olefin of 1-pentene and 3-methyl-1-butene is obtained as a (co)polymerization component.

[0248] Here, "contains" means that the whole film (a) is composed of (co)polymer (α) and the case where part of film (a) is composed of (co)polymer (α). Therefore, the film (...

no. 2 approach

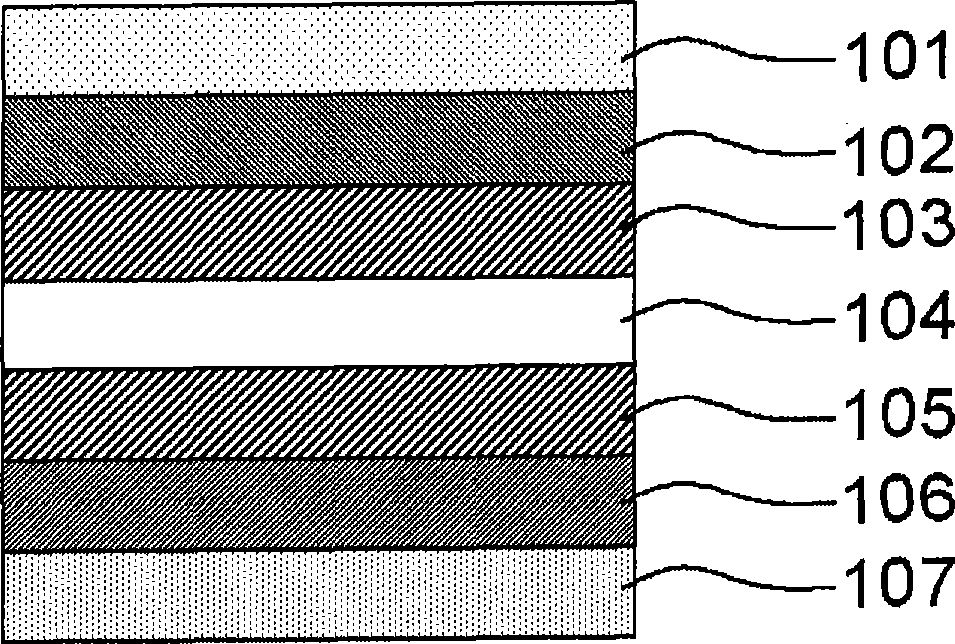

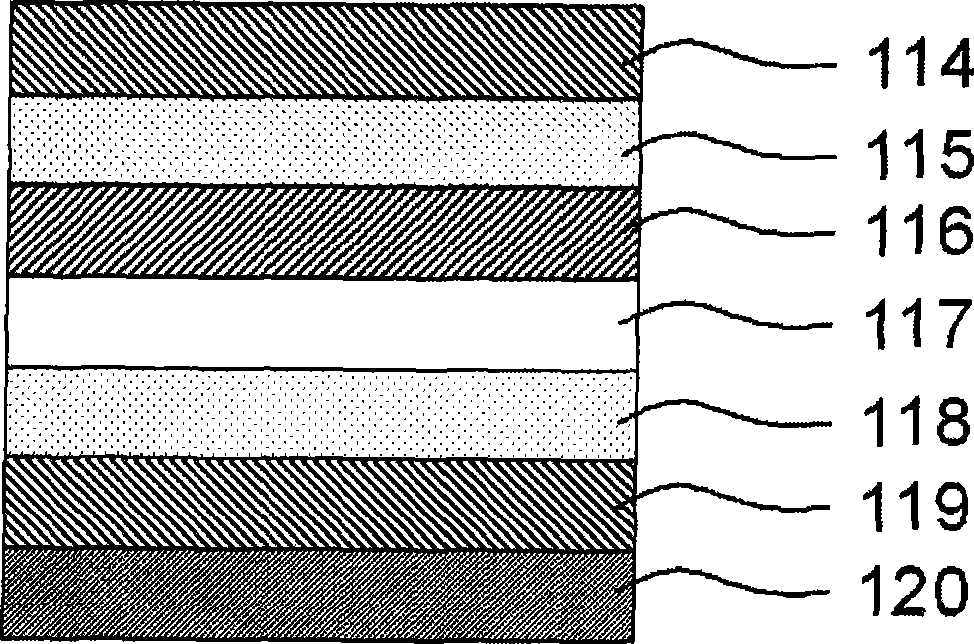

[0343] (Optical Parts (Optical Elements))

[0344] This embodiment relates to an optical component having at least one film (a) comprising a (co)polymer (α) using a compound selected from 4-methyl-1-pentene, 3 At least one olefin among methyl-1-pentene and 3-methyl-1-butene is obtained as a (co)polymerization component. Details of the (co)polymer (α) and film (a) in this embodiment are the same as those described in the first embodiment.

[0345] A (co)polymer obtained by using at least one olefin selected from 4-methyl-1-pentene, 3-methyl-1-pentene and 3-methyl-1-butene as a (co)polymerization component ) The film (a) of the polymer (α) is an optical film whose retardation becomes smaller as the wavelength is shorter, and is an optical film with stable optical properties, low cost, light weight, and less environmental load. Therefore, the optical film using this optical film Parts are practically of high value.

[0346] The optical component in this embodiment preferably h...

no. 3 approach

[0360] The optical film used as the film (a) in the above embodiments may also have the following structures.

[0361] The optical film used as the film (a) in this embodiment contains at least A film of a (co)polymer (α) obtained by using an olefin as a (co)polymerization component.

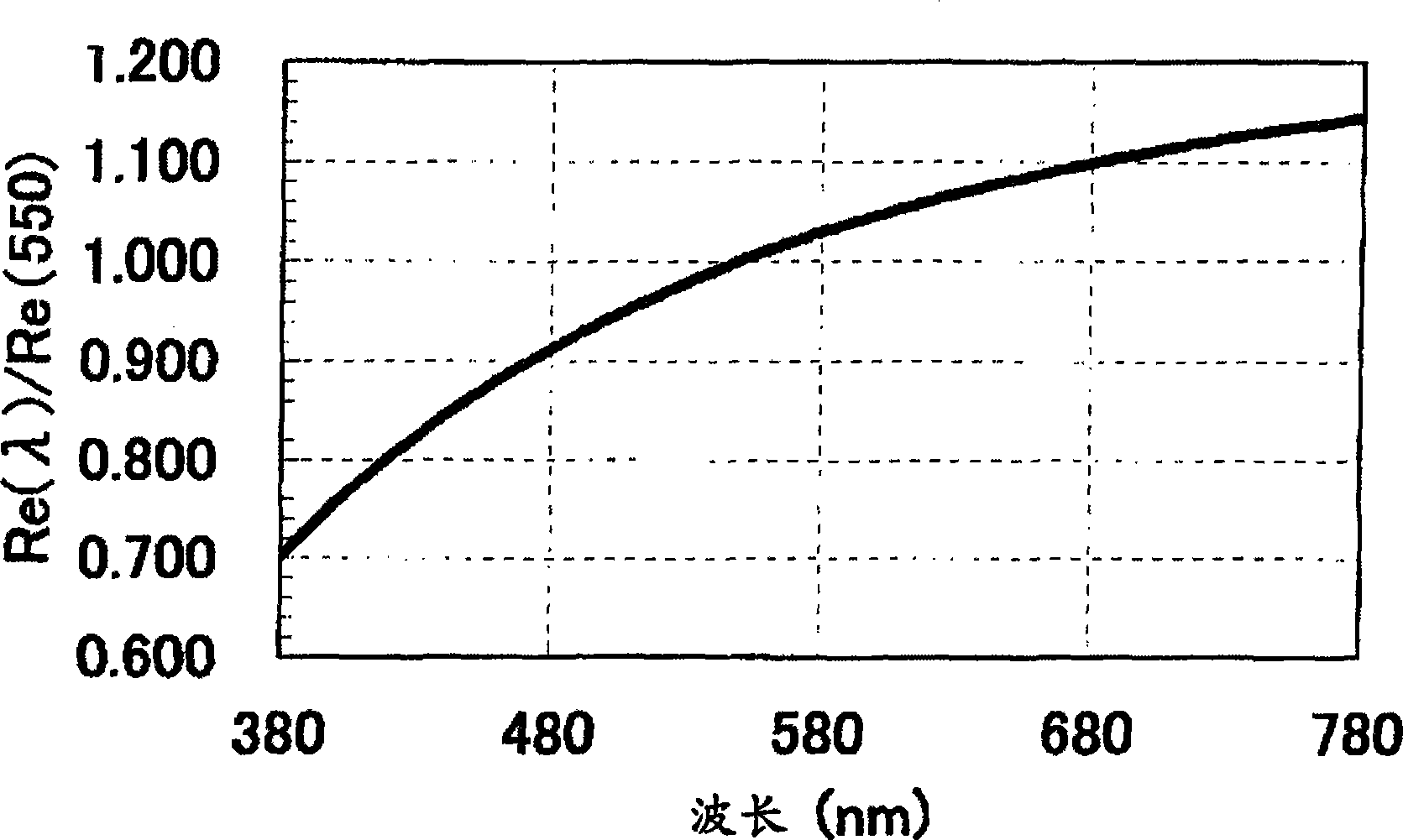

[0362] In addition, the optical film of this embodiment satisfies the following conditions.

[0363] R(450) / R(590)≤0.95

[0364] In the above formula, R(450) and R(590) represent the in-plane retardation of the above-mentioned optical film at wavelengths of 450 nm and 590 nm, respectively.

[0365] In the present embodiment, by satisfying the above formula, the optical film can effectively correct the wavelength dispersion of the retardation.

[0366] In addition, in order to more effectively correct the wavelength dispersion of retardation, the optical film preferably satisfies the following conditions. In this way, correction can be performed more effectively.

[0367] R(450) / R(590)≤0.9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com