Dynamic seal method and seal device of sintering pallet bottom and air box separated beam

A technology of sealing device and machine trolley, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the contradiction between the undertray and sealing of the trolley, the difficulty in controlling the negative pressure of the bellows ignition, Problems such as the increase of negative pressure of ignition and ventilation can achieve the effects of reducing ignition energy consumption, saving ignition fuel, and reducing negative pressure of ignition and ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

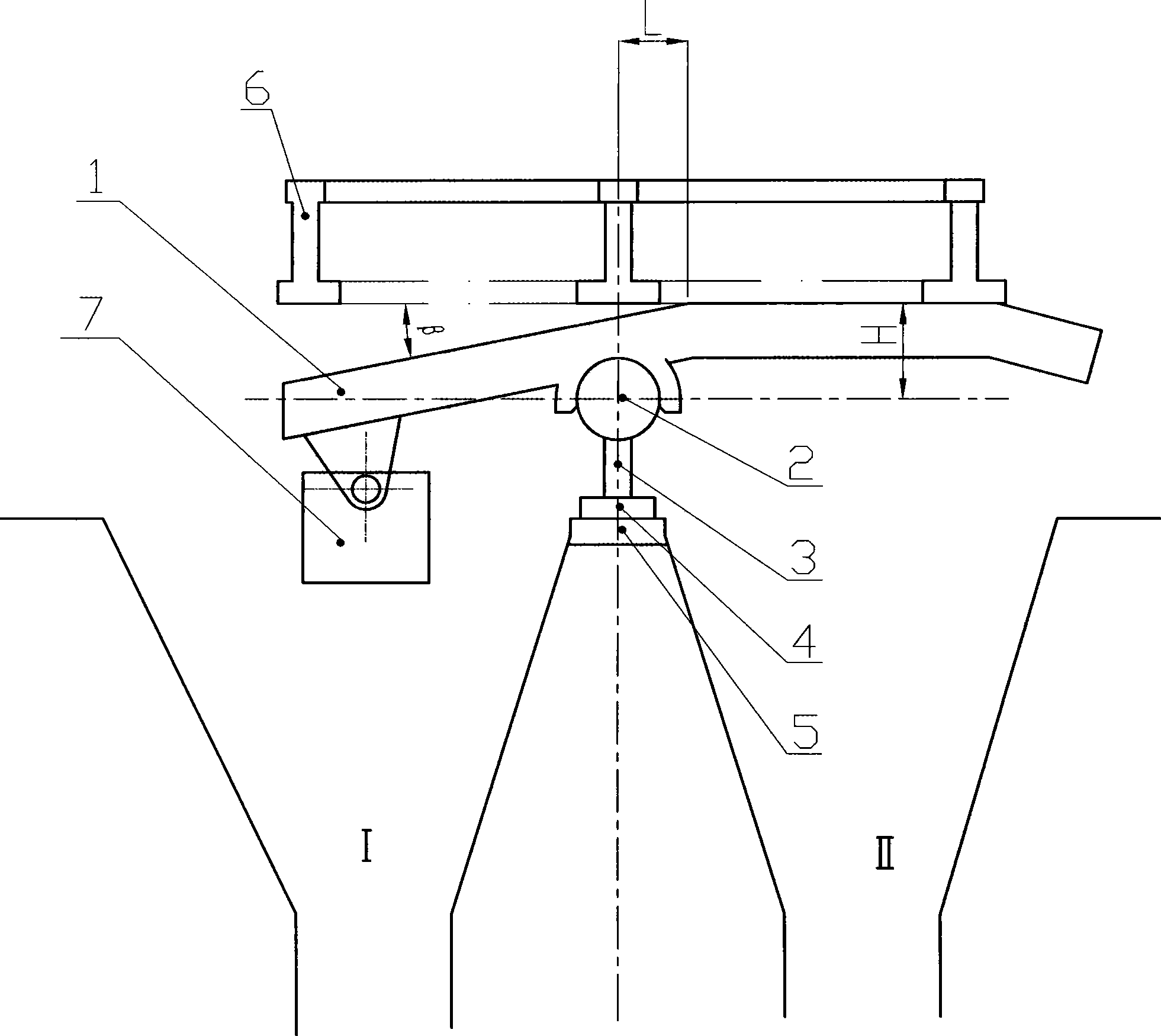

Examples

Embodiment 2

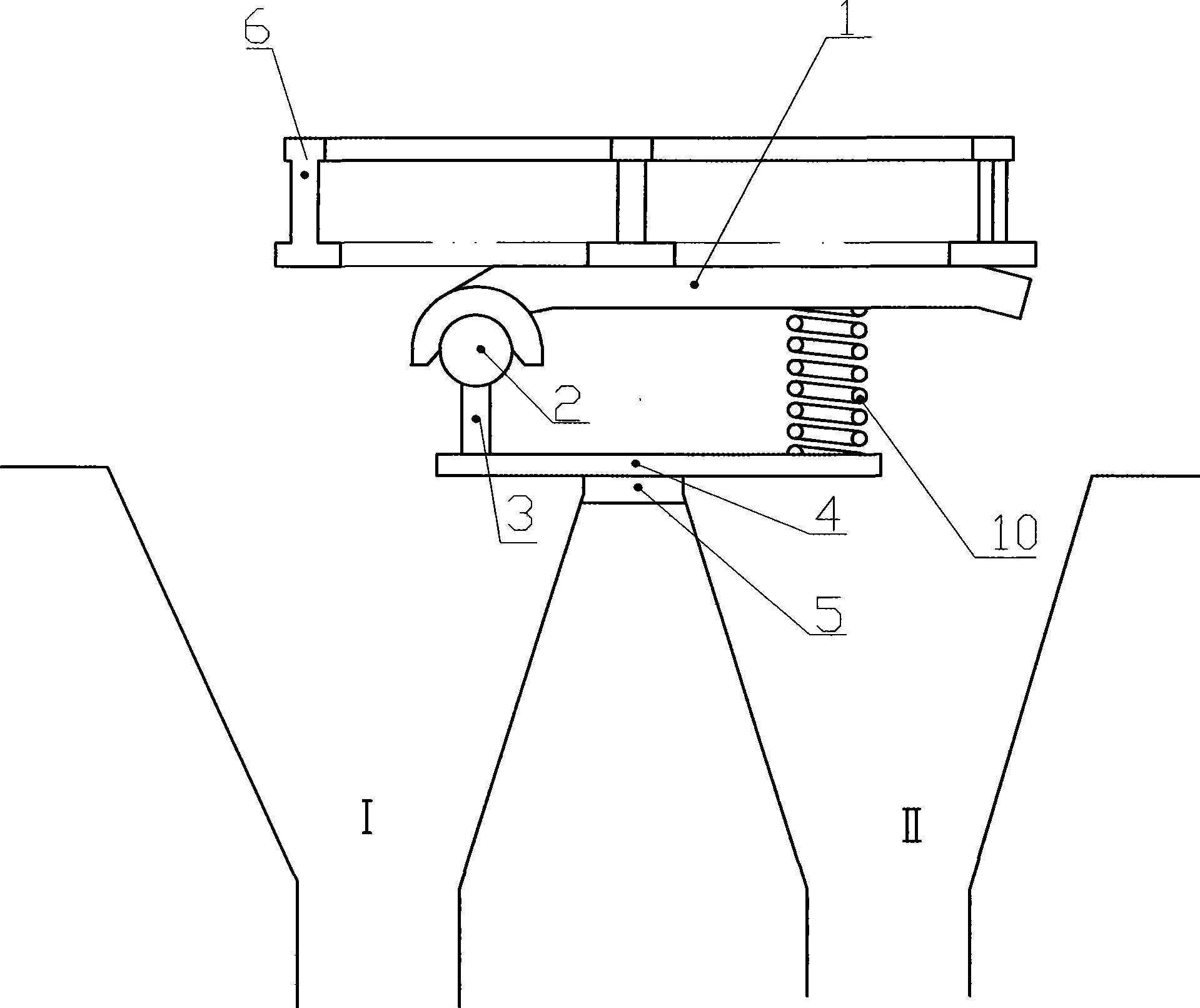

[0018] Embodiment 2 (see attached figure 2 ): the sealing cover plate 1 located under the bottom beam of the trolley is fixed on the bottom plate 4 through the pressure spring 10, and the bottom plate 4 is connected with the bellows partition beam 5; Positioned thrust stop iron 8; a flexible sealing plate 9 is arranged at the middle position between the sealing cover plate and the bottom plate. The spring force pushes up the sealing cover plate 1 and makes close contact with the bottom surface of the trolley beam to achieve the purpose of sealing and isolation. Thrust stopper 8 positions the sealing plate and allows space to move up and down.

Embodiment 3

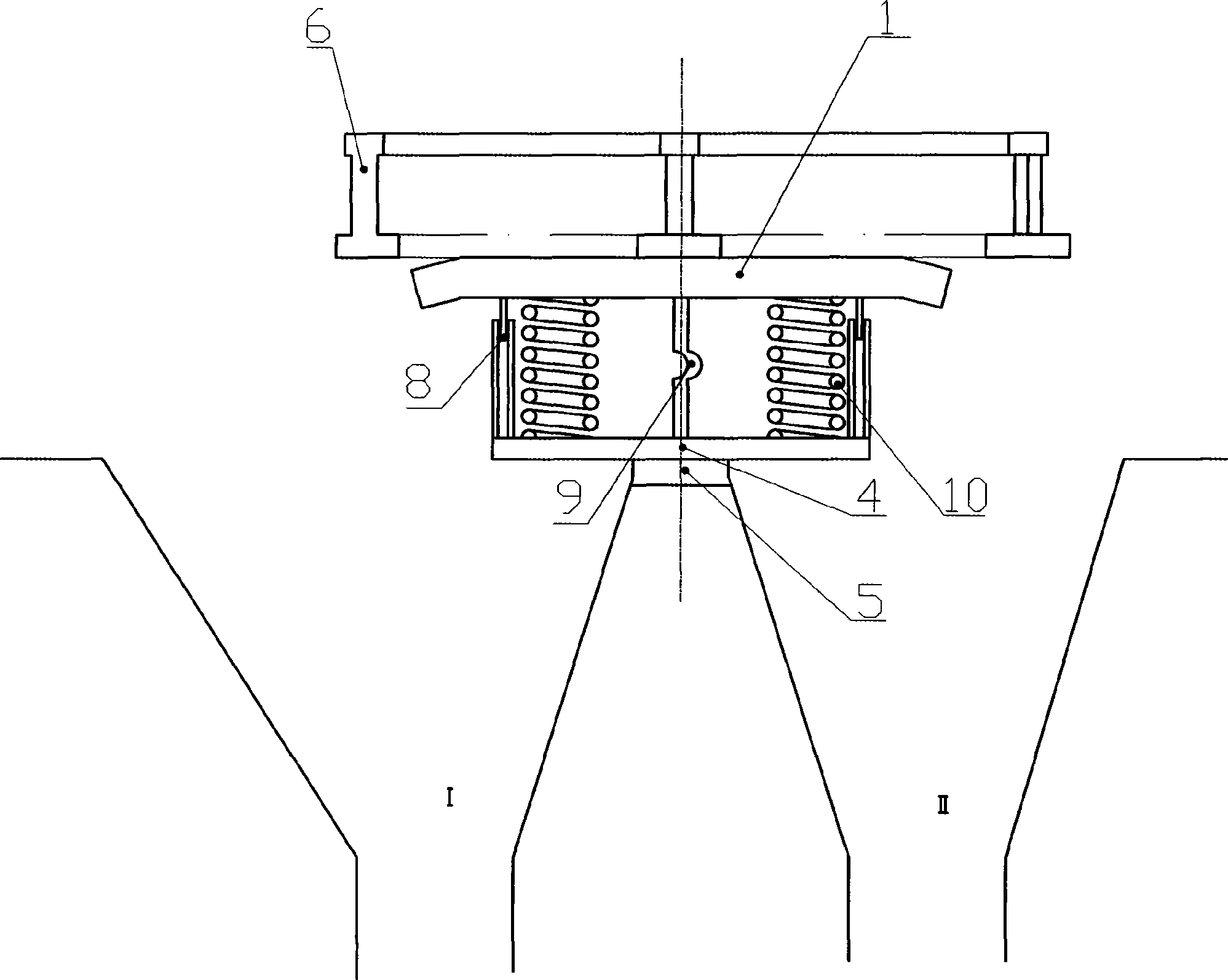

[0019] Embodiment 3 (see attached image 3 ): There is a semicircular groove under one end of the sealing cover plate 1, the groove is movably connected with the supporting shaft 2, the supporting shaft 2 is installed on one end of the bottom plate 4 through the vertical plate 3, and the bottom plate 4 is connected with the bellows partition beam 5; the sealing cover A compression spring 10 is arranged between the plate and the other end of the bottom plate. The other end of the sealing cover plate 1 is lifted up under the action of the elastic force of the spring, and contacts with the bottom surface of the trolley body crossbeam, realizing the effective sealing between the two bellows connecting partition beams and the bottom of the trolley body crossbeam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com