Vertical hanging ABS sensor detection drive device

A driving device and sensor technology, applied in measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as low reliability of ABS detection methods, inability to display measurement values and ranges, and inability to meet production needs, etc. To achieve the effect of reliable design, reasonable and reliable design, and strong product adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

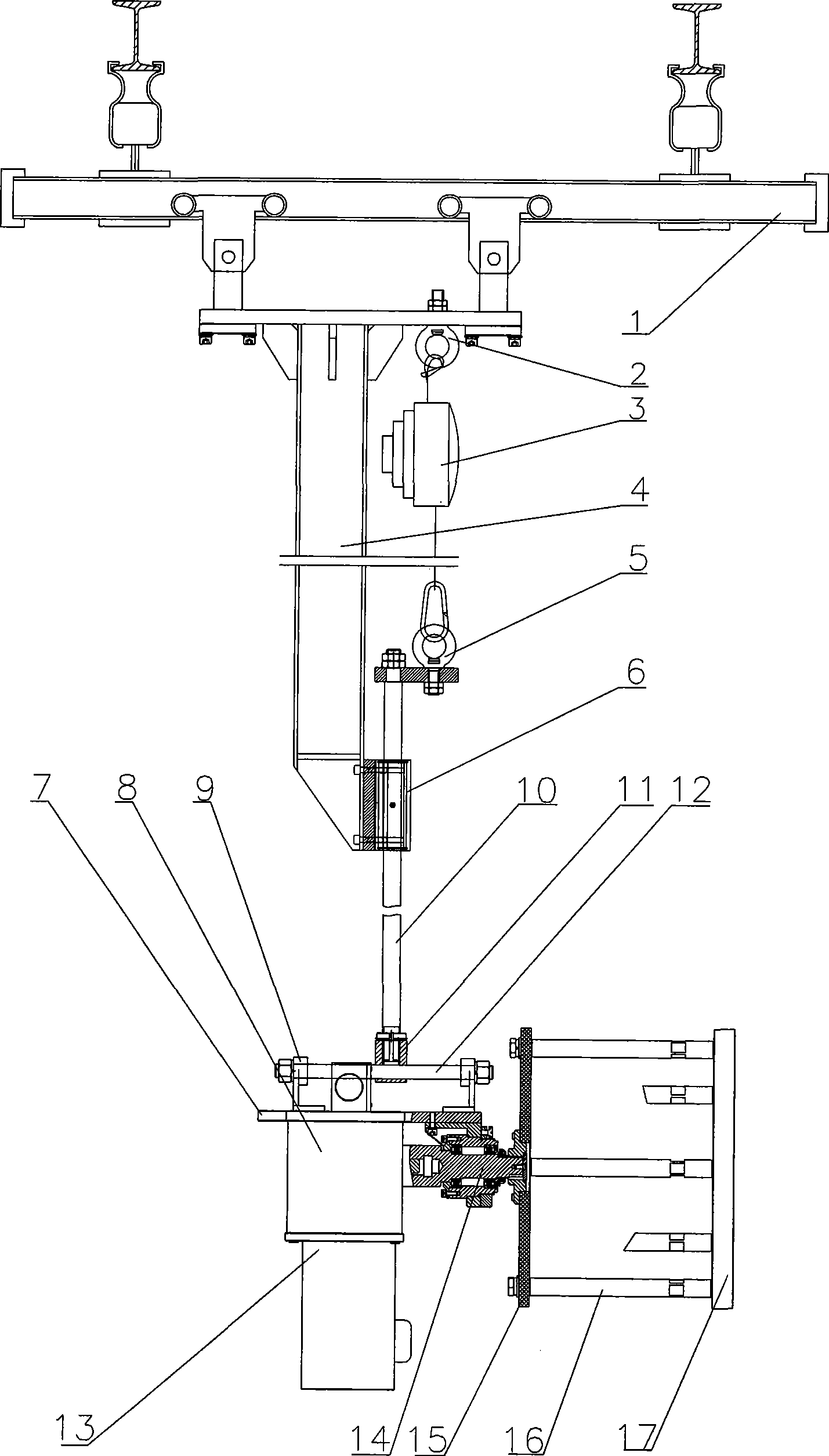

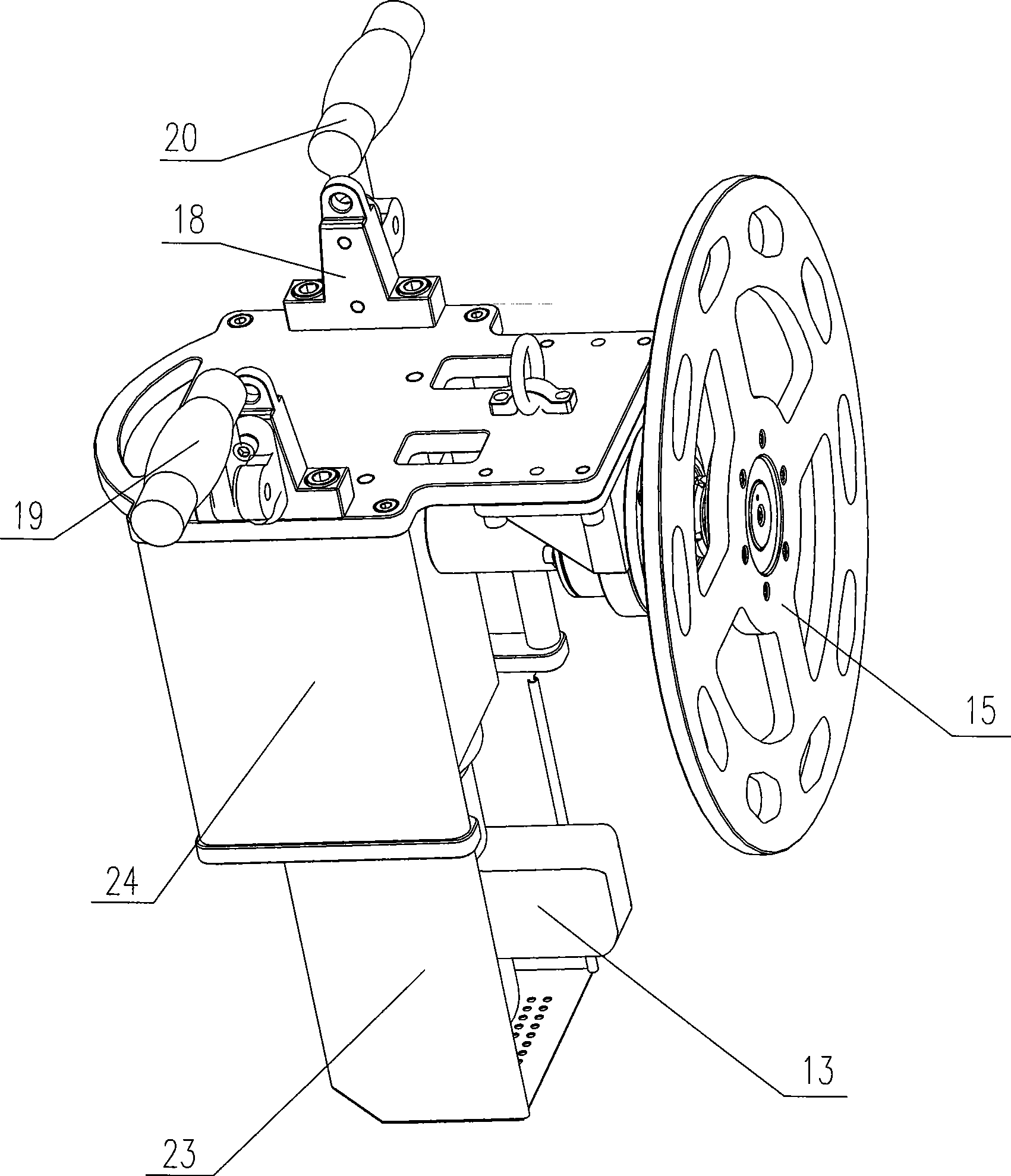

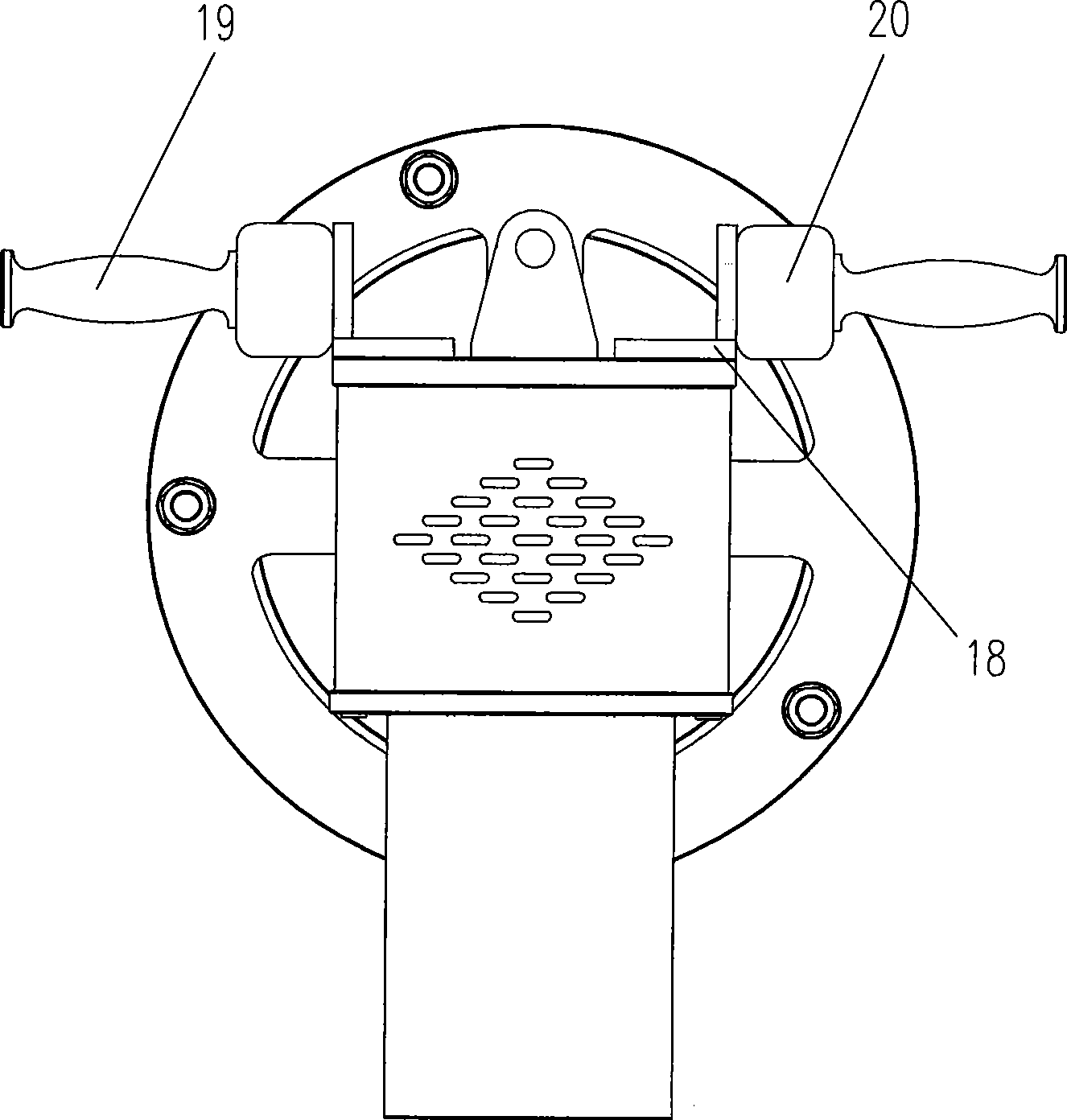

[0026] see figure 1 , figure 2 , the drive motor 13 is set upright, the horizontal mounting plate 7 is fixedly arranged on the reducer 8 of the drive motor 13, and the drive disc 15 is fixedly connected to the horizontal output shaft 14 of the reducer 8, and the drive disc 15 is connected to the hub through a connecting rod 16 On the drive plate 17; the horizontal mounting plate 7 is set on the lifting rod 12 through two hanger seats 9, and the lifting rod 12 is set on the guide shaft 10 through the connecting block 11; the guide shaft 10 is set on the end sleeve 6 of the cantilever 4 Among them, the cantilever 4 is installed on the upper beam track 1 through rollers, and a balancer 3 is set between the cantilever 4 and the guide shaft 10. The balancer 3 is connected to the cantilever 4 and the guide shaft 10 through the upper eyebolt 2 and the lower eyebolt 5 respectively. In between, the whole set of equipment is installed on the KBK upper beam track 1, and the whole set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com