Remote calibration method and system

A technology for remote calibration and to-be-calibrated, applied in measuring devices, instruments, measuring electrical variables, etc., can solve problems such as inconvenience, reduce the use efficiency of instruments and equipment, waste of resources, etc., to improve efficiency, promote the flow of information, and ensure accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further discussed below in conjunction with the accompanying drawings. The standard source takes FLUKE 5520A as an example, and the instrument to be calibrated takes FLUKE 45 as an example. The parallel connection method is adopted, and the data cable adopts DB9 crossover line.

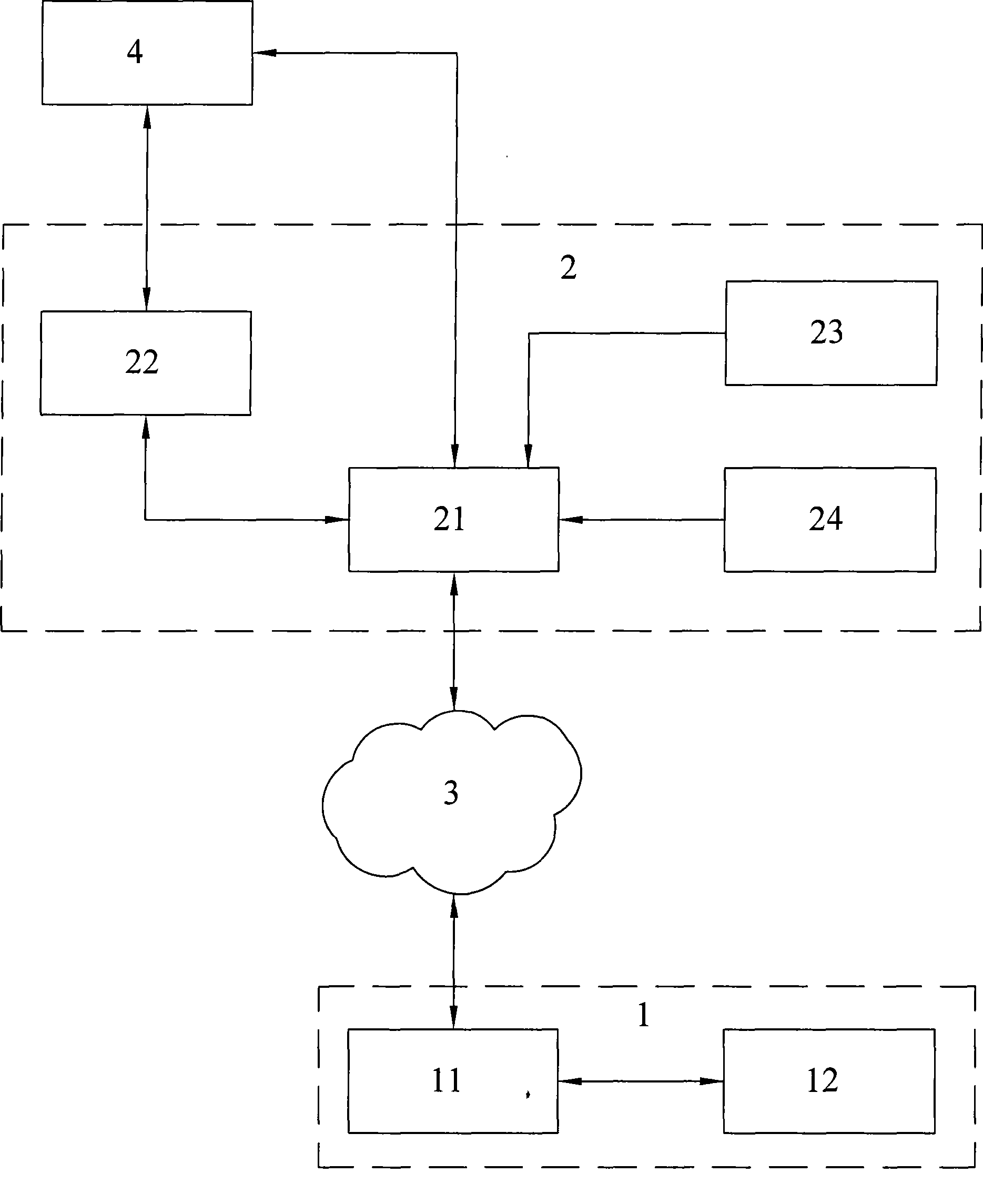

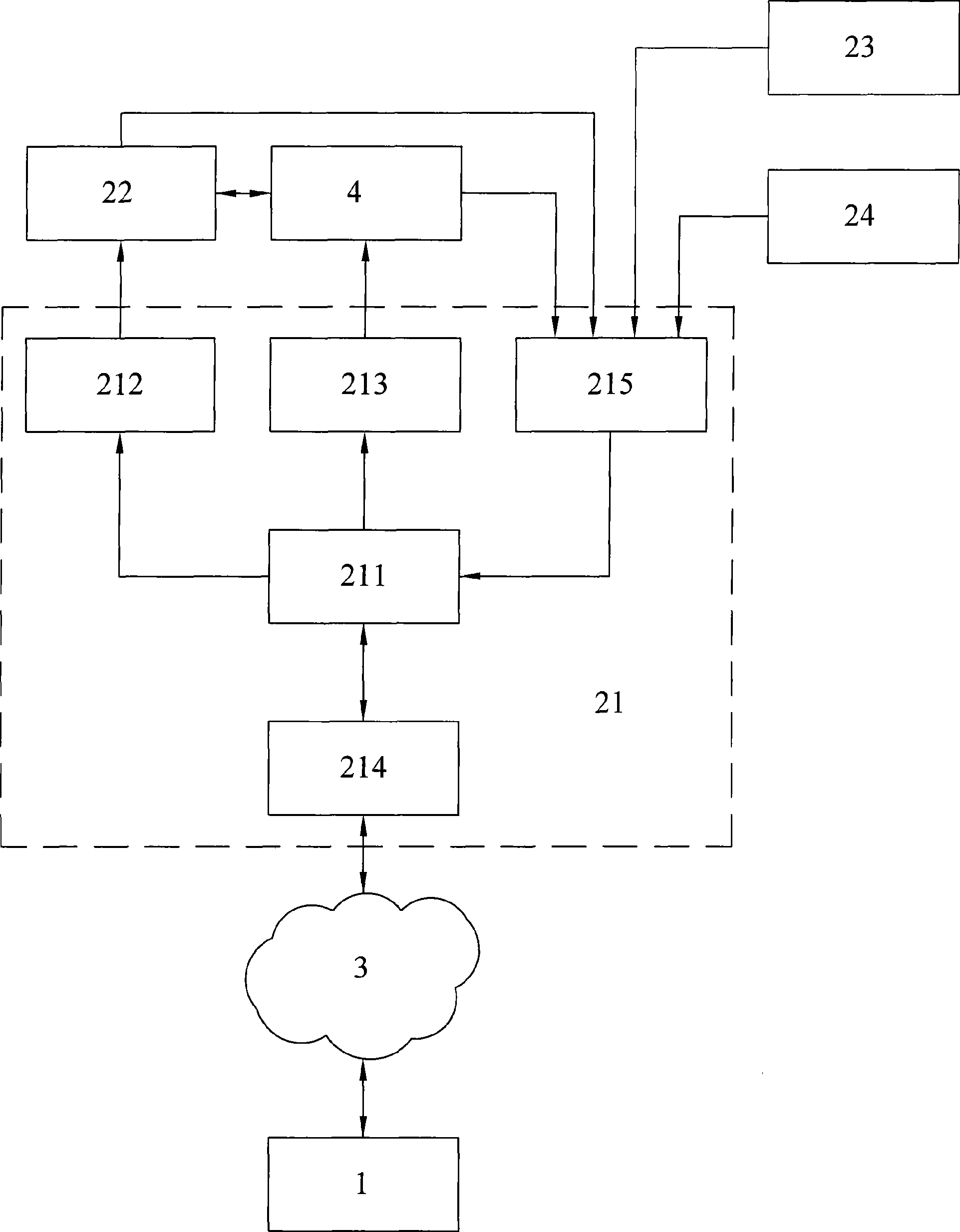

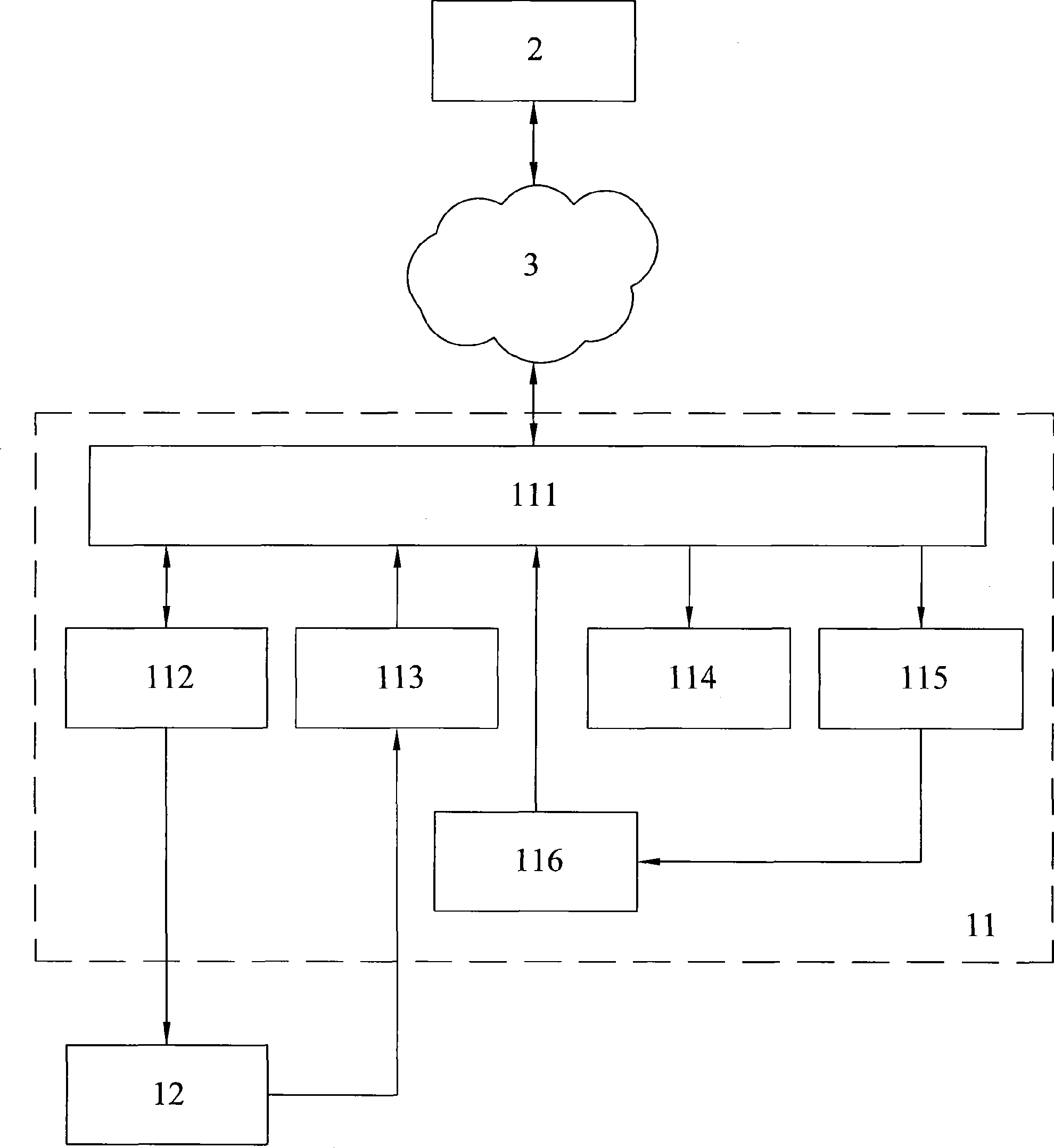

[0036] Such as figure 1 A remote calibration system shown includes: a remote client 2 for calibrating the instrument to be calibrated; a calibration center 1 for setting, reviewing calibration items and monitoring the calibration process; and a network 3 connecting the remote client 2 and the calibration center 1 . The remote client 2 includes a remote calibration host 21 , and a standard source 22 connected to the remote calibration host 21 , a temperature probe 23 and a monitoring camera 24 . The standard source 22 is connected to the instrument 4 to be calibrated through a dedicated cable, and the instrument 4 to be calibrated and the standard source 22 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com