Induction heating cooking device

A technology of induction heating and induction heating coils, which is applied in the direction of induction heating and induction heating devices, and can solve problems such as complicated structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

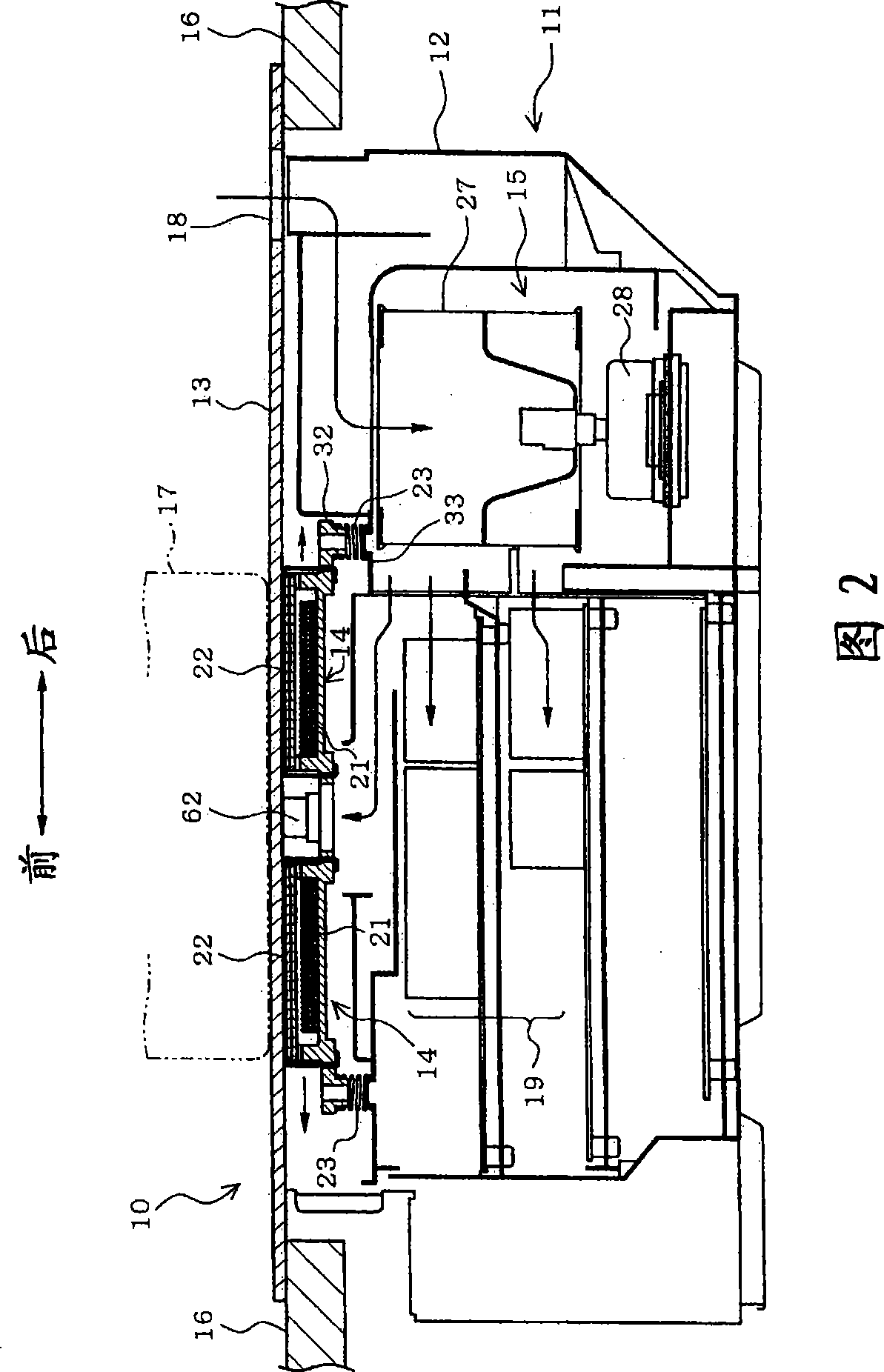

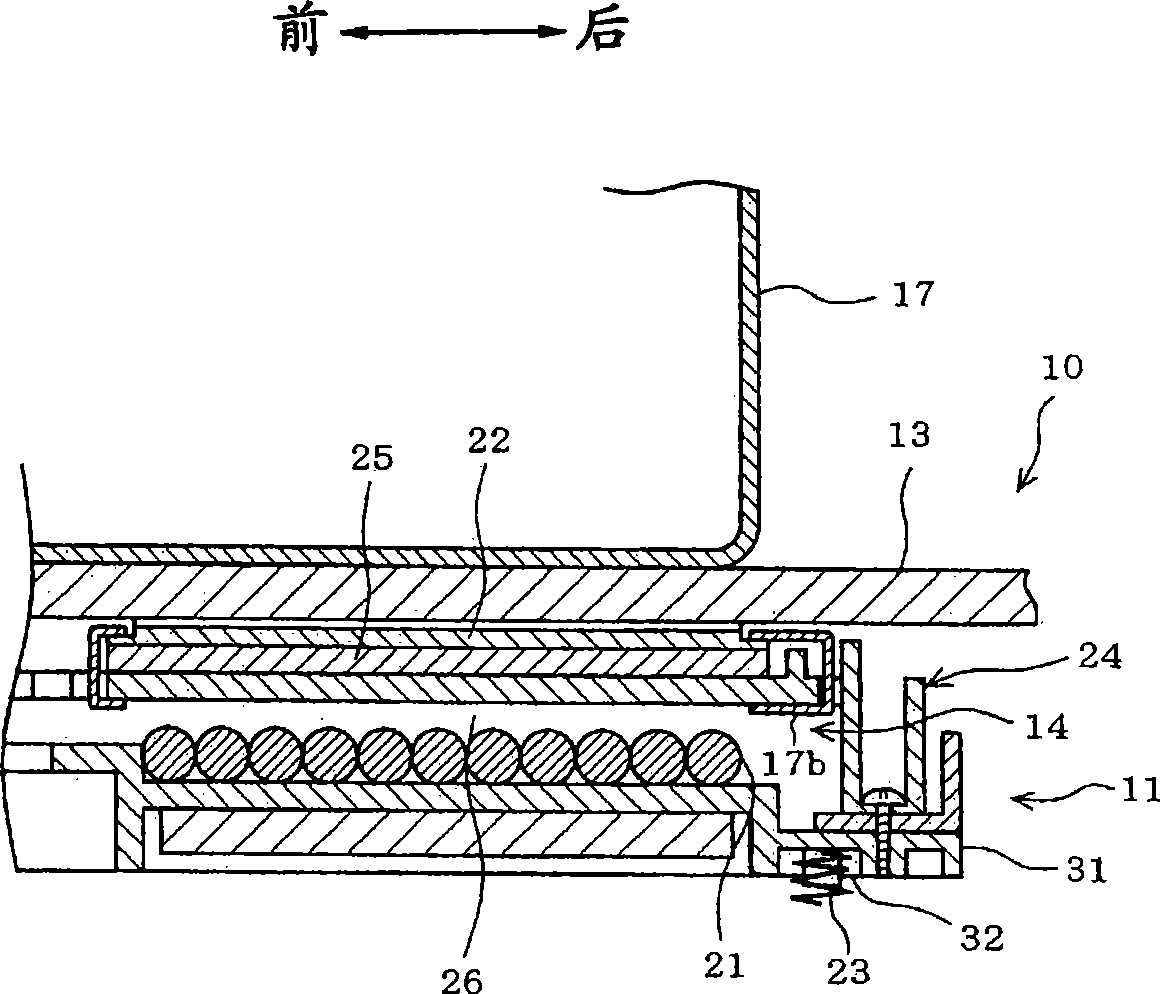

[0030] Fig. 2 shows an induction heating cooker according to Embodiment 1 of the present invention. The induction heating cooker 10 includes a main body case 12 and a top plate 13 constituting a cooker main body 11 . The induction heating cooker 10 is installed so that the top plate 13 is upward in the direction of gravity. In addition, in FIG. 2 , the left side is the front side of the induction heating cooker 10 , and the right side is the rear side of the induction heating cooker 10 . The induction heating cooker 10 includes a heating unit 14 and a cooling fan unit 15 in a cooker body 11 .

[0031]The main body casing 2 forms the main outer shape of the induction heating cooker 10 . The top plate 13 covers the top of the main body casing 12 . The cooker main body 11 is assembled to, for example, a countertop 16 of a kitchen unit. By means of this, the cooker main body 11 and its top plate 13 will be exposed from the work surface 16 . On the upper surface of the top pla...

Embodiment 2

[0072] Figure 7 The plate-shaped heating body of the induction heating cooker of Example 2 of this invention is shown.

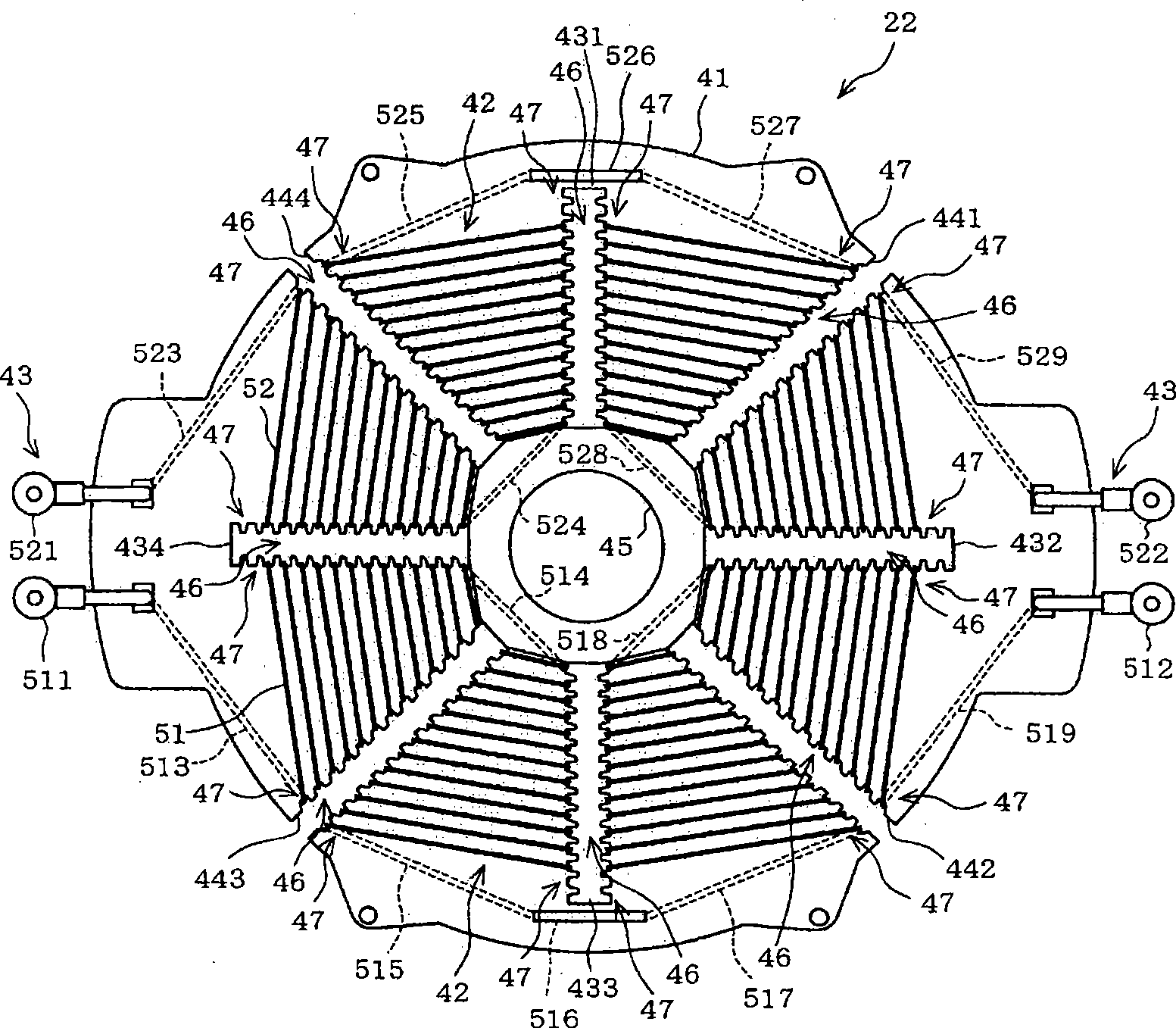

[0073] In Example 2, such as Figure 7 As shown, the plate heating body 122 has an insulating substrate 141 and a strip heater 142 . Figure 7 It is a schematic diagram of the plate-shaped heating body 122 viewed from the top plate 13 side, that is, a schematic diagram of the upper surface side. In the case of Example 2, the insulating substrate 141 is formed in an annular shape. The insulating substrate 141 has concavo-convex portions 146 on the inner peripheral side and the outer peripheral side in the diameter direction, respectively. The uneven portion 146 is formed with unevenness in the diameter direction of the insulating substrate 141 . The tape heater 142 is wound around the insulating substrate 141 while being folded back at the concave-convex portion 146 on the inner peripheral side and the concave-convex portion 146 on the outer peripheral s...

Embodiment 3

[0082] Next, Fig. 2 also shows a schematic configuration of an induction heating cooker according to Embodiment 3 of the present invention. The induction heating cooker 10 includes a main body casing 12 and a top plate 13 constituting a cooker main body 11 .

[0083] The induction heating cooker 10 is installed so that the top plate 13 is upward in the direction of gravity. In addition, in FIG. 2 , the left side is the front side of the induction heating cooker 10 , and the right side is the rear side of the induction heating cooker 10 . The induction heating cooker 10 includes a heating unit 14 and a cooling fan unit 15 in a cooker body 11 .

[0084] The main body casing 12 forms the main outline of the induction heating cooker 10 . The top plate 13 covers the top of the main body casing 12 . Cooker main body 11 is assembled, for example, to countertop 16 of a kitchen unit. With this, the cooker main body 11 and its top plate 13 will be exposed on the work surface. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com