Self-locking valve with valve cap

A self-closing, bonnet technology, applied in the direction of closing, safety valves, balance valves, etc., can solve problems such as large reset force, achieve the effects of simplifying the structure, saving materials, and improving air back-suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

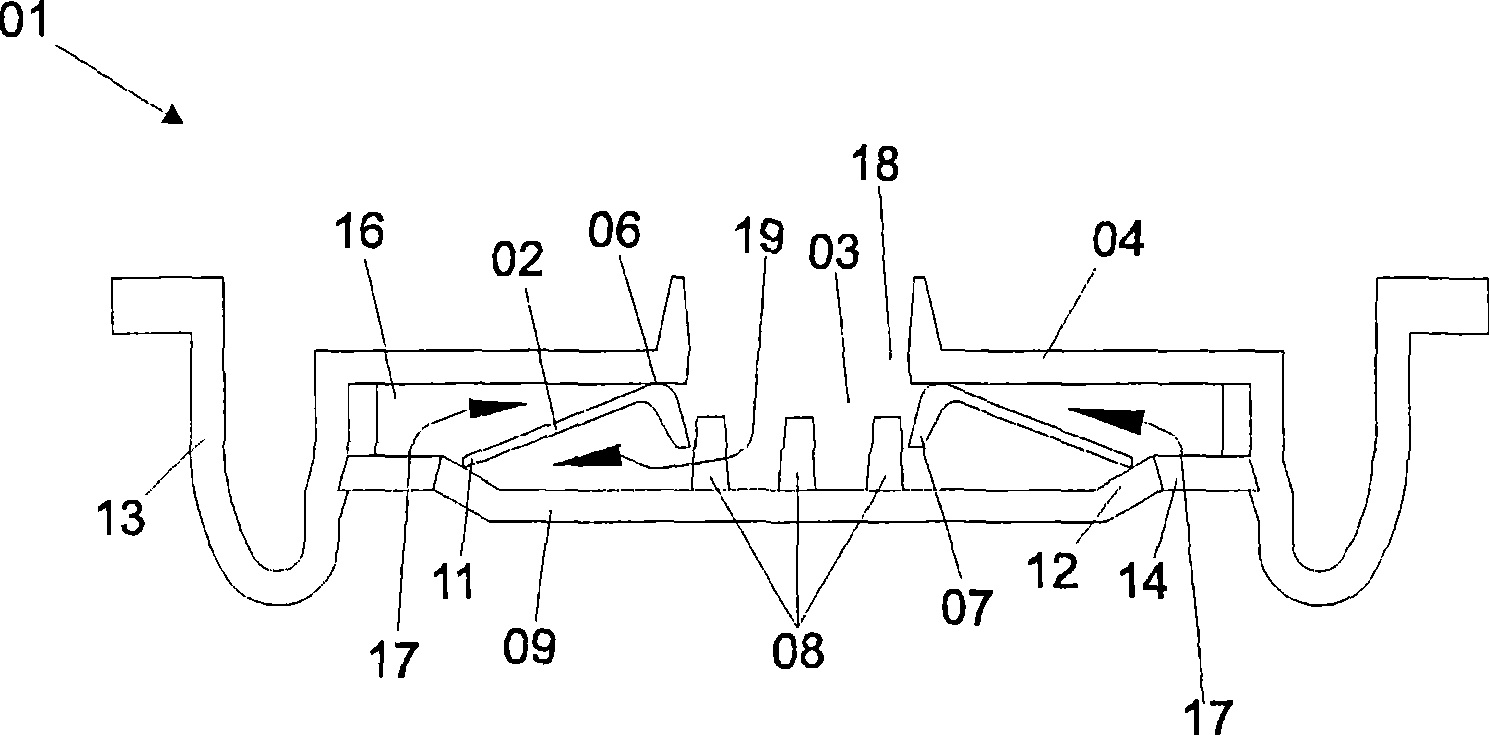

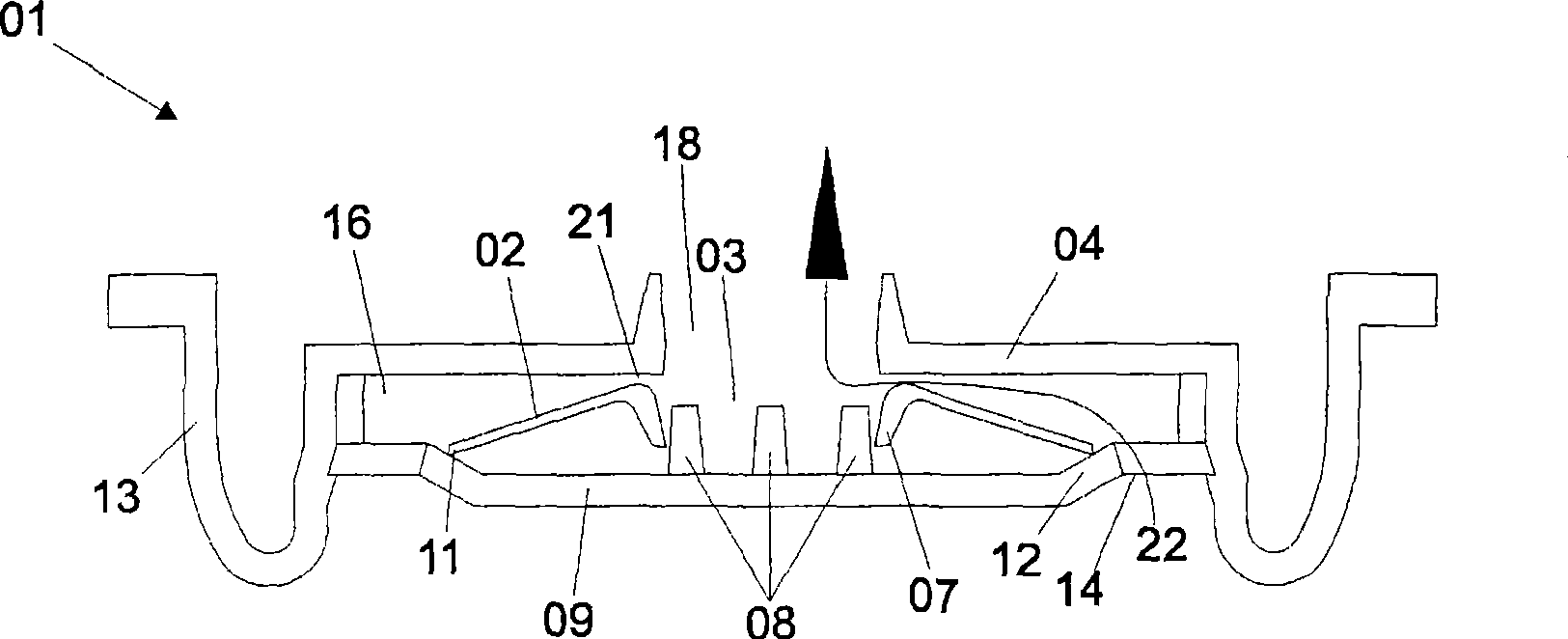

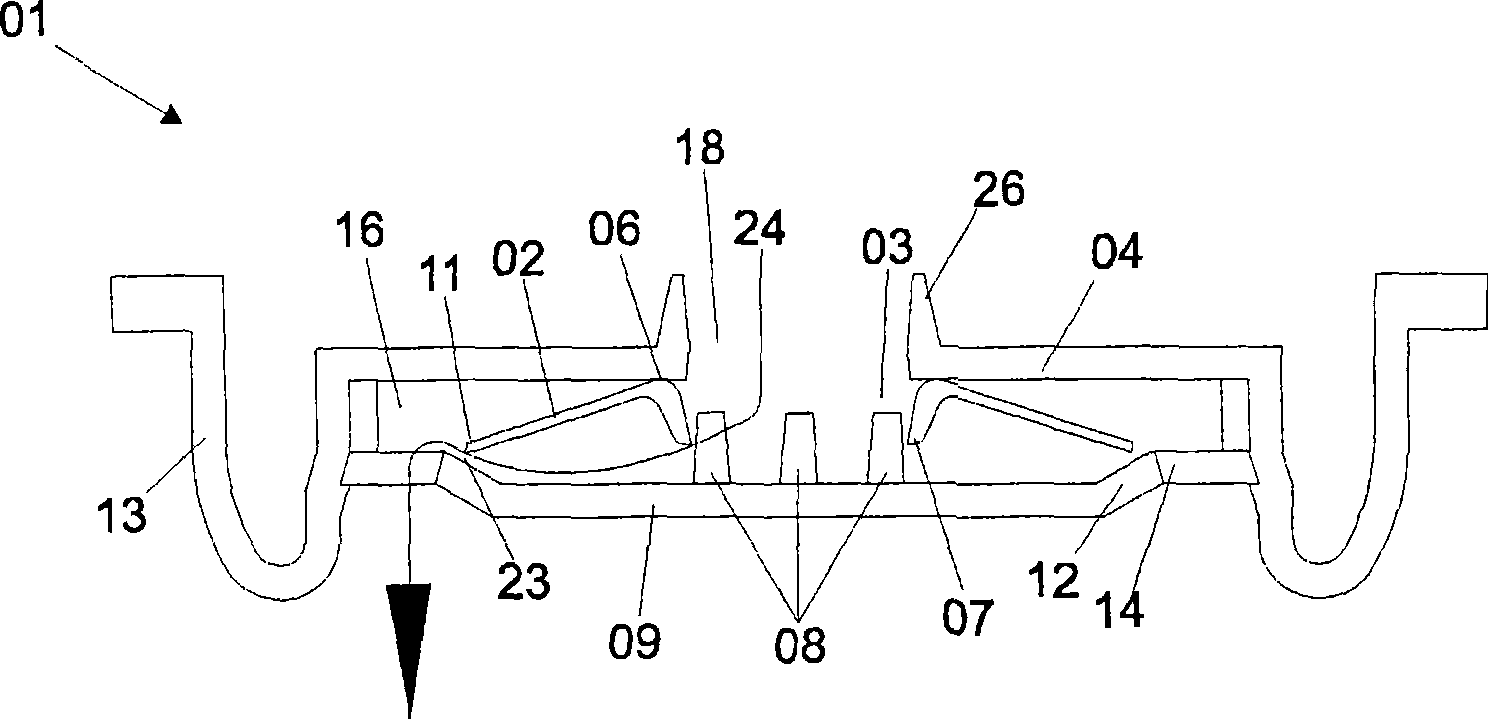

[0024] figure 1 A cross-sectional view of a first embodiment of the self-closing valve 01 according to the invention is shown in the closed position. Generally speaking, for the understanding of the figures, the valve 01 is designed to fit on a container (not shown), for example by fitting into the neck of a squeeze bottle.

[0025] The valve 01 comprises an annular valve membrane 02 having an annular central guide opening 03 . The valve membrane 02 is substantially in the form of a disk spring and also exhibits a relative spring characteristic. exist figure 1 The position of the valve membrane 02 when the valve 01 is closed is shown in . In this closed position, the valve membrane 02 is pressed with its periphery of the guide opening 03 onto the valve cover 04 . The circular bearing surface 06 thus formed seals the valve membrane 02 against the valve cover 04 . On the side of the valve membrane 02 opposite the bearing surface 06 , the guide opening 03 has a surrounding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com