Valve cap for a non-return valve

A check valve, valve body technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., to achieve the effect of improving hysteresis characteristics and optimizing switching characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

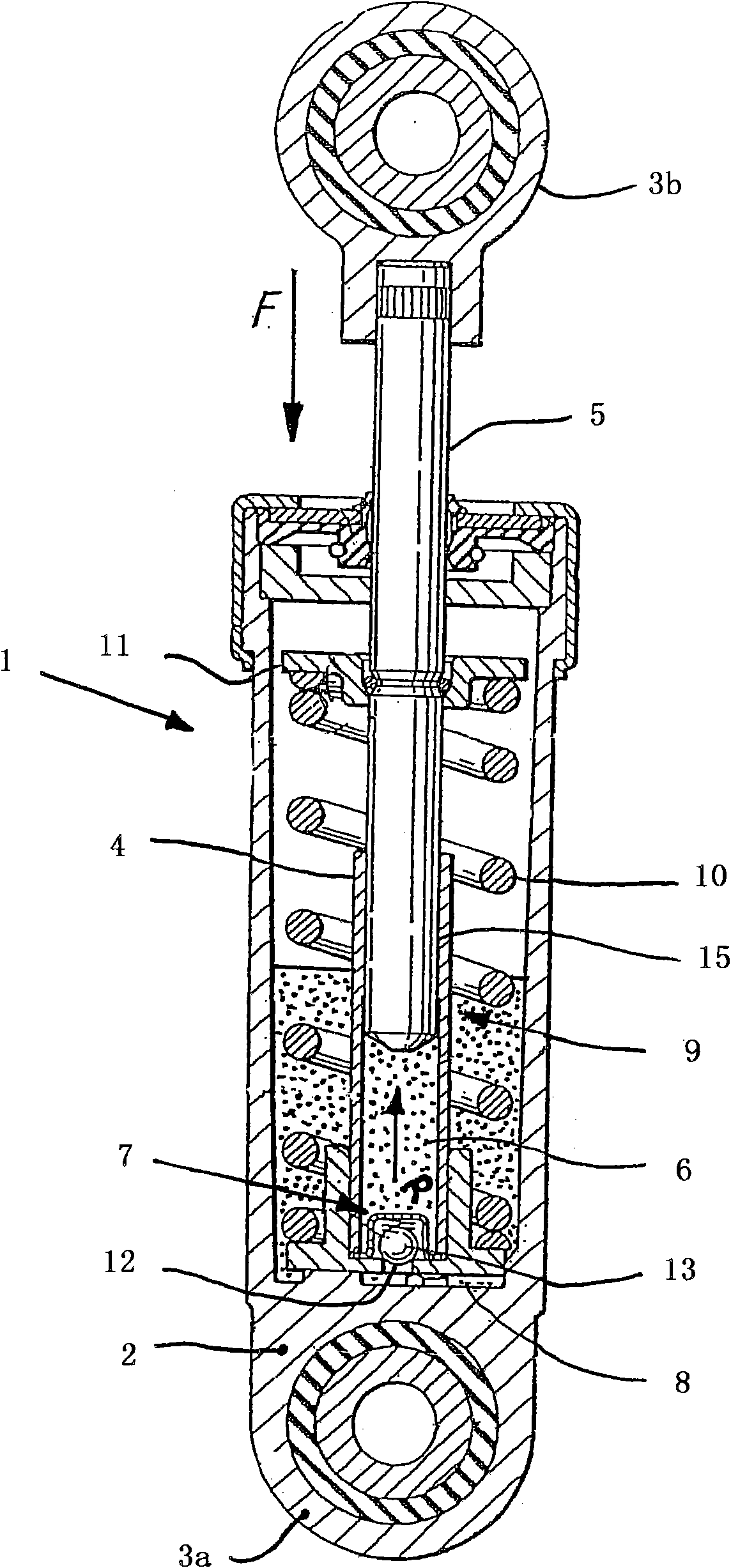

[0028] exist figure 1 The hydraulic tensioning system 1 is shown in cutaway diagram, the hydraulic tensioning system 1 is assigned to the traction mechanism transmission, and through figure 1 The tensioning roller, not shown in , directly interacts with the traction mechanism of the traction mechanism drive. The structure comprises a housing 2 , which is fixedly and pivotably connected, for example, to the housing of the internal combustion engine via fastening eyelets 3 a. The housing 2 forms a component having a pot-like configuration, in which a cylinder 4 is mounted centrally, which is defined to accommodate a linearly displaceable piston 5 . The cylinder 4 associated with the piston 5 delimits a pressure chamber 6 filled with hydraulic fluid, which is connected via a channel 8 of the housing 2 and a flow section 12 of the cylinder 4 to a reservoir 9 for hydraulic fluid. The reservoir 9 is delimited on the outside by the housing 2 and on the inside by the shell surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com