Additional method of draw-bead technique for corner part of external covering of vehicle

A technology for outer cover parts and corner parts, applied in the field of die stamping, can solve problems such as obvious wrinkling and wrinkling, and achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in detail in conjunction with the accompanying drawings.

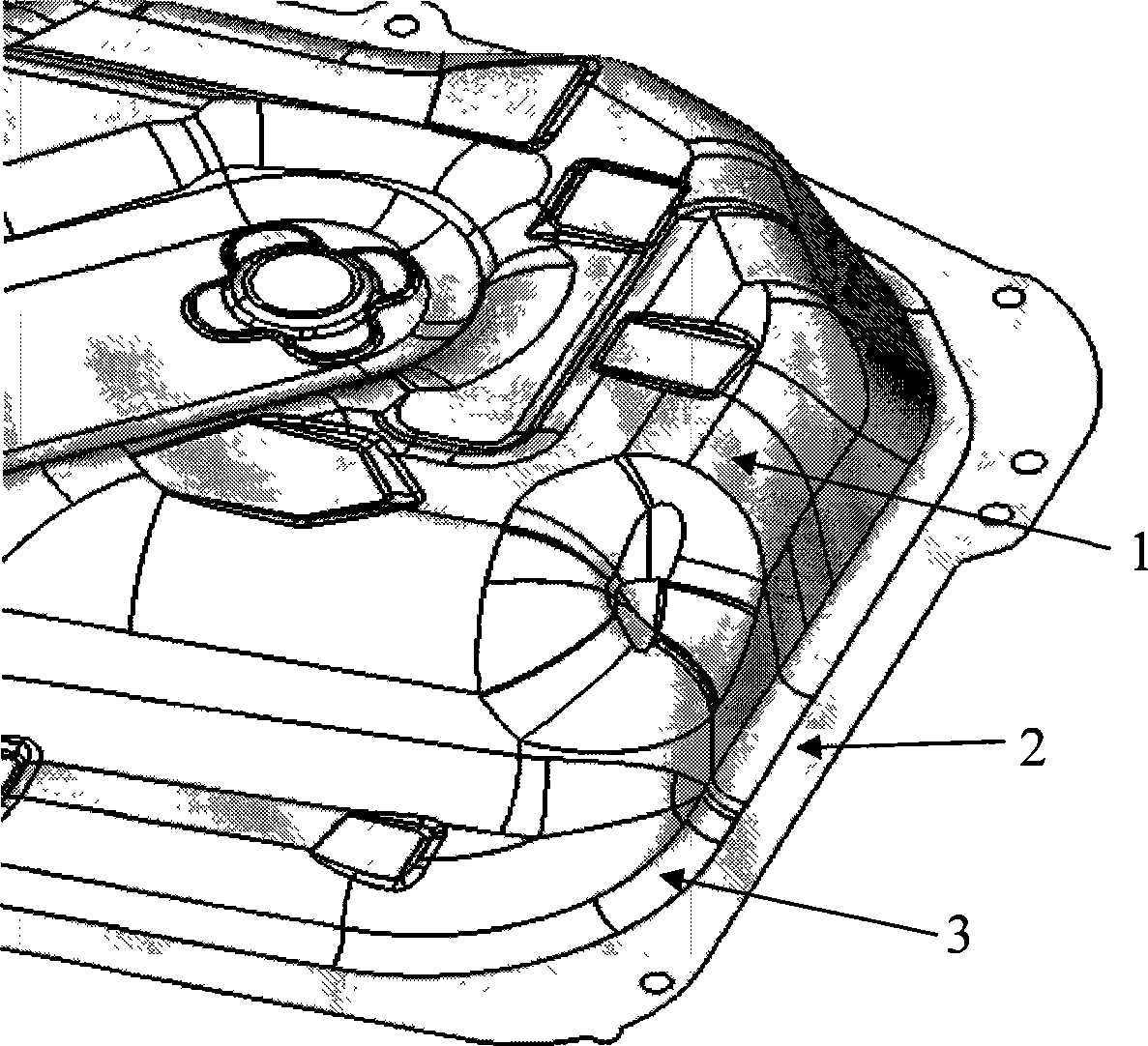

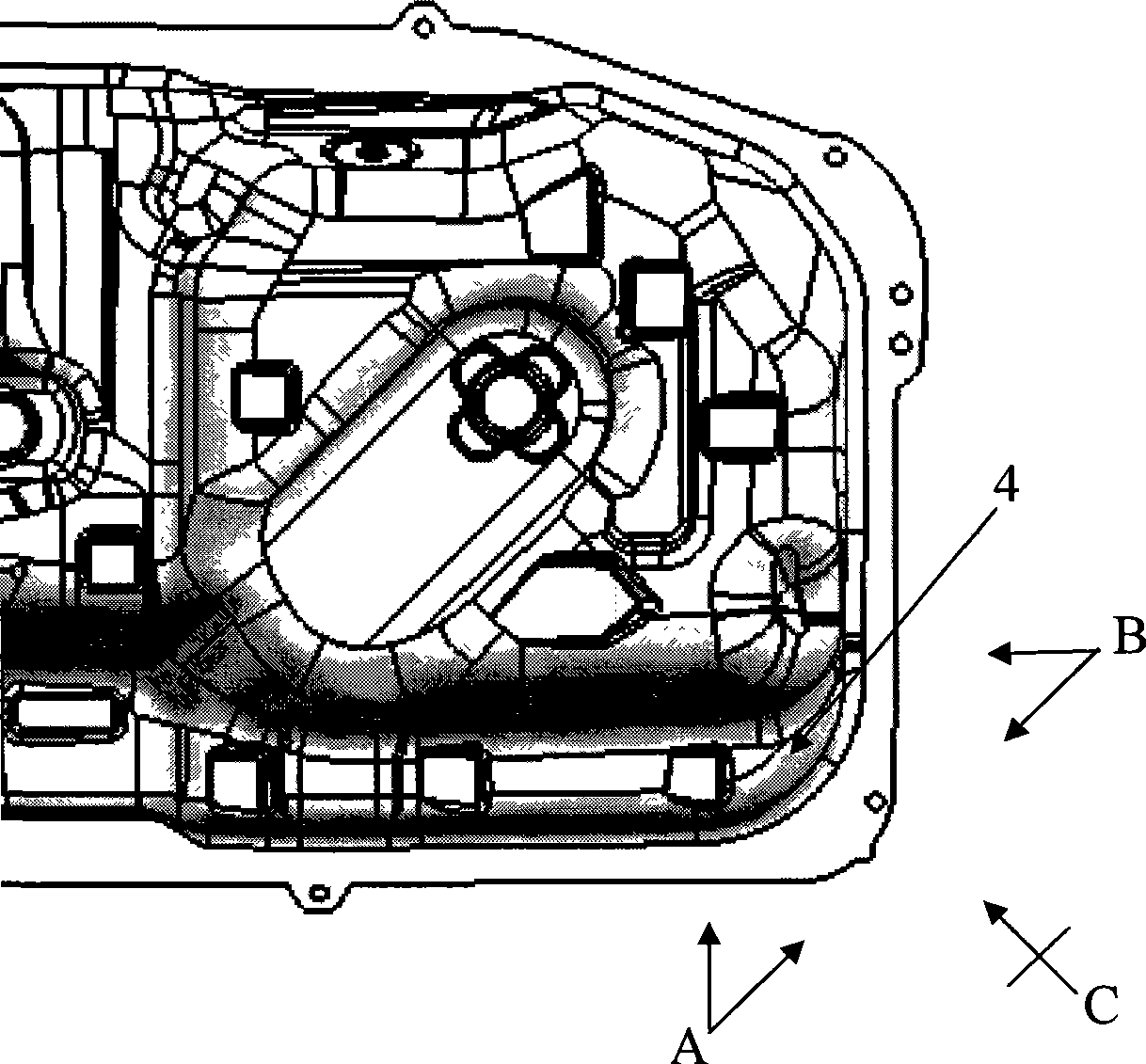

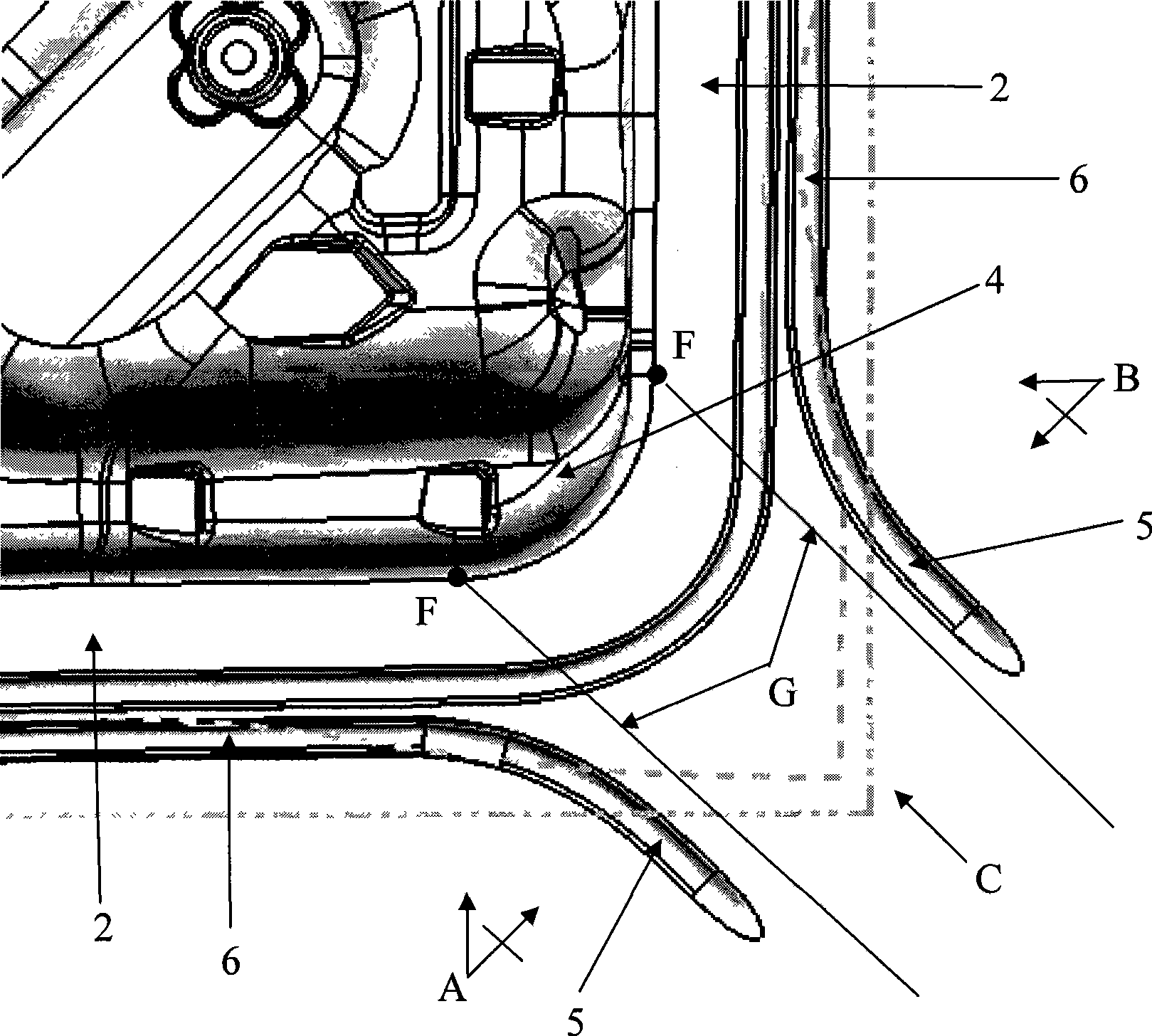

[0012] The vehicle outer cover to which the present invention is applicable includes a main body 1 and a flange surface 2, and the main body 1 and the flange surface 2 are connected by a rounded surface 3, such as figure 1 As shown, and the fillet angle of the corner portion 4 of the main body 1 is about 90 degrees, as figure 2 shown. Of course, it should be understood that the present invention is also applicable to parts whose corner fillet angle is less than 90 degrees, and here only the case of 90 degrees is taken as an example for illustration.

[0013] Usually, as a general part, when supplementing the process, it is usually necessary to extend outward along the peripheral edge of the part to obtain the fillet surface of the die and the binder surface, and then along the binder surface as required Drawbeads are set on the peripheral edge. But, for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com