Ceramic / metal composite structure and manufacturing method thereof

A technology of metal composite structure and manufacturing method, which is applied in the field of ceramic/metal composite structure and its manufacturing, can solve the problems of reliability influence of high-power electronic parts, decreased heat dispersion ability, large thermal stress, etc., and achieves good electrical connection and heat dissipation. effect of function

Inactive Publication Date: 2009-05-27

段维新

View PDF0 Cites 44 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This thermal stress is very large, which has a great influence on the bonding strength of the aluminum oxide sheet and the copper sheet, and after being packaged with electronic parts that generate heat, after tens of thousands of on-off cycles of the electronic parts, if the aluminum oxide sheet And th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

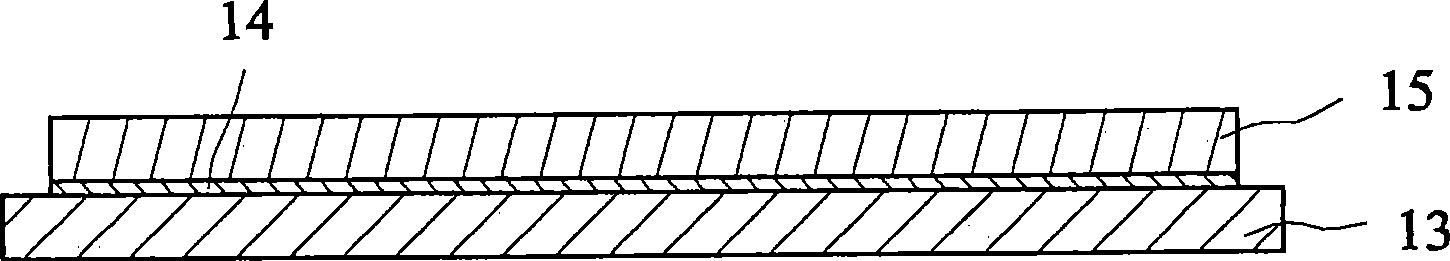

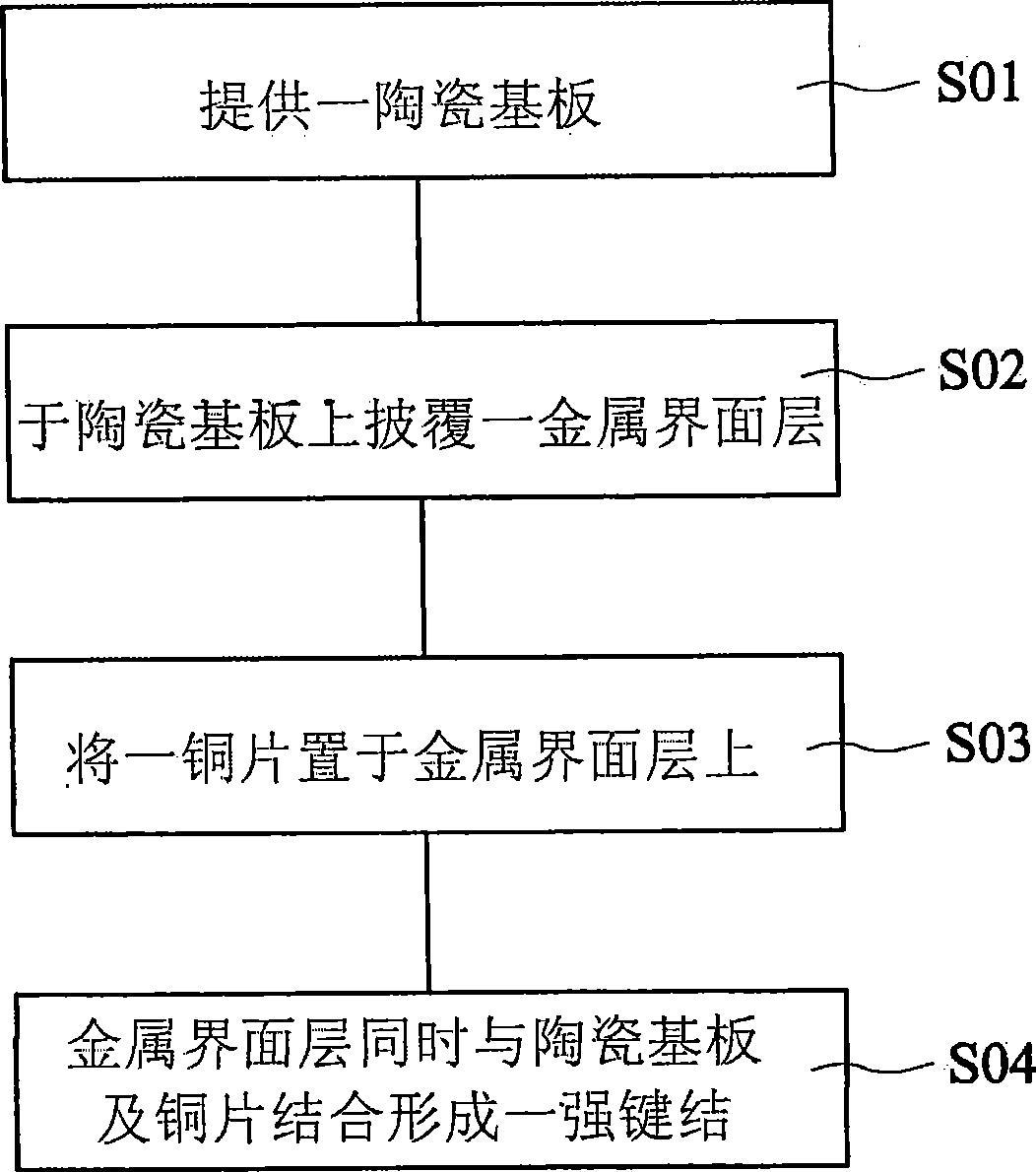

The invention relates to a method for manufacturing a ceramic/metal composite structure. The method comprises the following steps: providing a ceramic substrate; coating a metal interfacial layer on the ceramic substrate; placing a copper sheet on the metal interfacial layer; and heating the ceramic substrate, the metal interfacial layer and the copper sheet to allow the metal interfacial layer to combine with the ceramic substrate and the copper sheet to form a strong bond. The invention also discloses a ceramic/metal composite structure.

Description

technical field [0001] The invention relates to a ceramic / metal composite structure and a manufacturing method thereof, in particular to a composite structure formed by combining an aluminum oxide layer and a copper layer and a manufacturing method thereof. Background technique [0002] When electrons flow in electronic parts, heat will be generated, and the heat generation will increase the resistance, hinder the flow of electrons, and then greatly affect the function of electronic parts. Under the current situation that the manufacturing technology of electronic parts is greatly improved, the line width in electronic parts is getting smaller and smaller, but the circuit density is getting higher and higher, so the heat generated by electronic parts is also increasing rapidly. Taking a computer's central processing unit (Central Processing Unit, CPU) as an example, the earliest version of Intel's Pentium only needs to be packaged with a heat dissipation power of 16W. Howev...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B37/02

Inventor 段维新杨聪仁

Owner 段维新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com