High bearing antifriction nano-coating

A nano-coating, high-load-bearing technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of construction workers' health damage, low friction, bearing resistance, and many components, and achieve convenient construction and good wear resistance. The effect of reducing friction and high load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

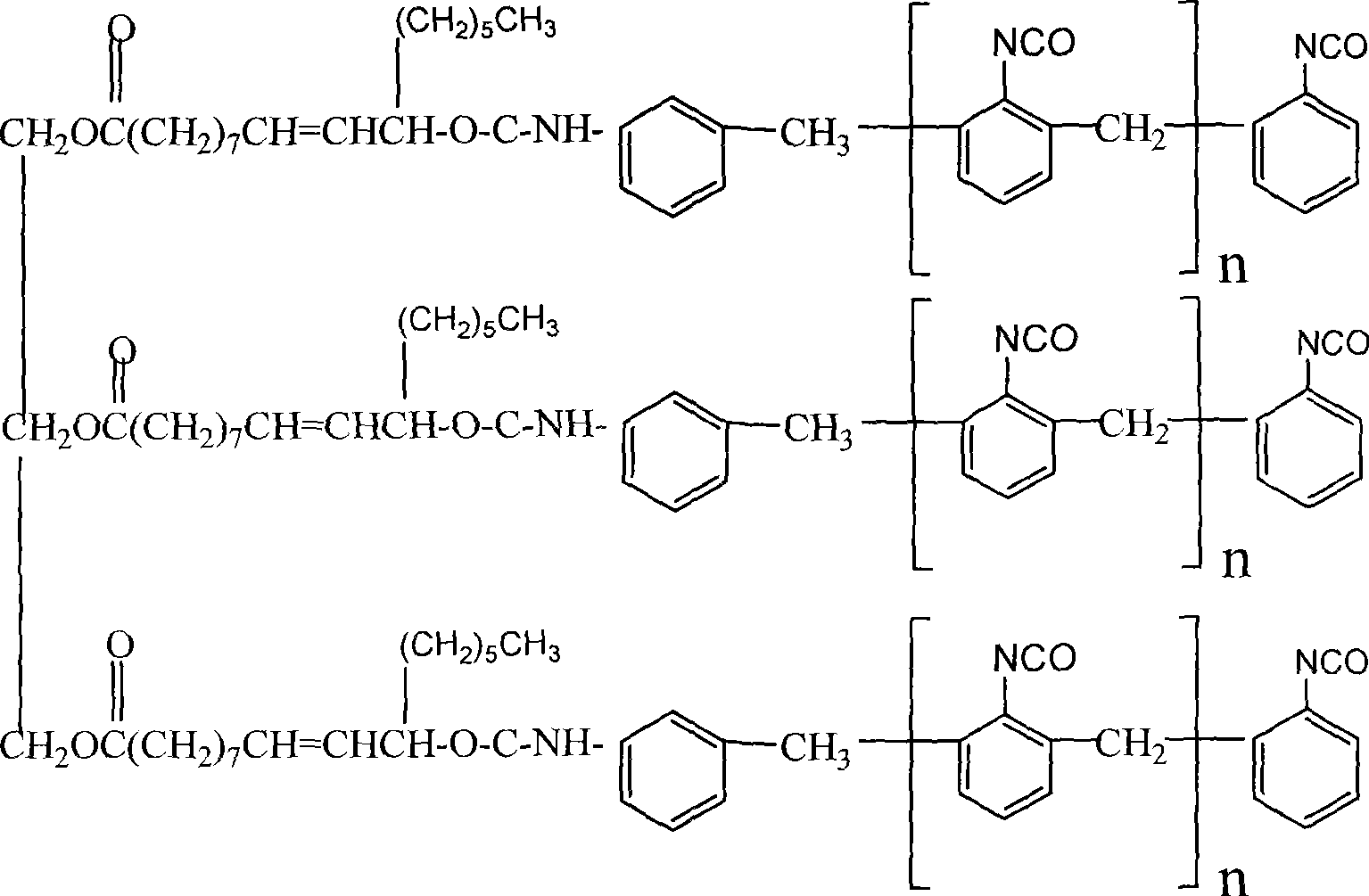

Image

Examples

Embodiment 1

[0040] One-component moisture-curing polyurethane adhesive 100 parts

[0041] Teflon wax 25 parts

[0042] 10 parts of melamine urea complex

[0043] Acetone and ethyl acetate mixed solvent (volume ratio 1:1) 200 parts

[0044] Titanium dioxide nanotubes 0.5 parts

[0045] Weigh the above-mentioned substances and stir them evenly, disperse them in an ultrasonic wave, and spray them with a spray gun under 0.1-0.2Mpa nitrogen to remove water, oil, and rust on the surface of No. 45 steel block, at room temperature, 320N, 2.56m / s The wear life is 8870m / μm -1 , The coefficient of friction is 0.147.

Embodiment 2

[0047] One-component moisture-curing polyurethane adhesive 100 parts

[0048] 30 parts of polytetrafluoro wax

[0049] 15 parts of melamine urea complex

[0050] Acetone and ethyl acetate mixed solvent (volume ratio 3:7) 200 parts

[0051] Titanium dioxide nanotubes 1 part

[0052] Weigh the above-mentioned substances and stir them evenly, disperse them in an ultrasonic wave, and spray them with a spray gun under 0.1-0.2Mpa nitrogen to remove water, oil, and rust on the surface of No. 45 steel block, at room temperature, 320N, 2.56m / s The wear life is 8570m / μm -1 , The coefficient of friction is 0.152. At room temperature, 1620N, wear life at 2.56m / s is 1280m / μm -1 , The coefficient of friction is 0.04-0.06.

Embodiment 3

[0054] One-component moisture-curing polyurethane adhesive 100 parts

[0055] Teflon wax 15 parts

[0056] 10 parts of melamine urea complex

[0057] Acetone and ethyl acetate mixed solvent (volume ratio 4:6) 150 parts

[0058] Titanium dioxide nanotubes 1 part

[0059] Weigh the above-mentioned substances and stir them evenly, disperse them in an ultrasonic wave, spray them with a spray gun under 0.1-0.2Mpa nitrogen on the surface of No. 45 steel block that has been dewatered, degreased, and derusted, and put the cured coating in liquid paraffin Soaked for 60 days, at room temperature, 320N, 2.56m / s wear life is 7270m / μm -1 , The coefficient of friction is 0.151.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap