Method for weaving modified warp-rib fabric on air-jet loom

A technology for air-jet looms and fabrics, applied to looms, textiles, papermaking, textiles, etc., can solve the problems of weft insertion rate (low output, etc.), reduce production costs, increase weft insertion rate, and increase weft insertion rate and output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

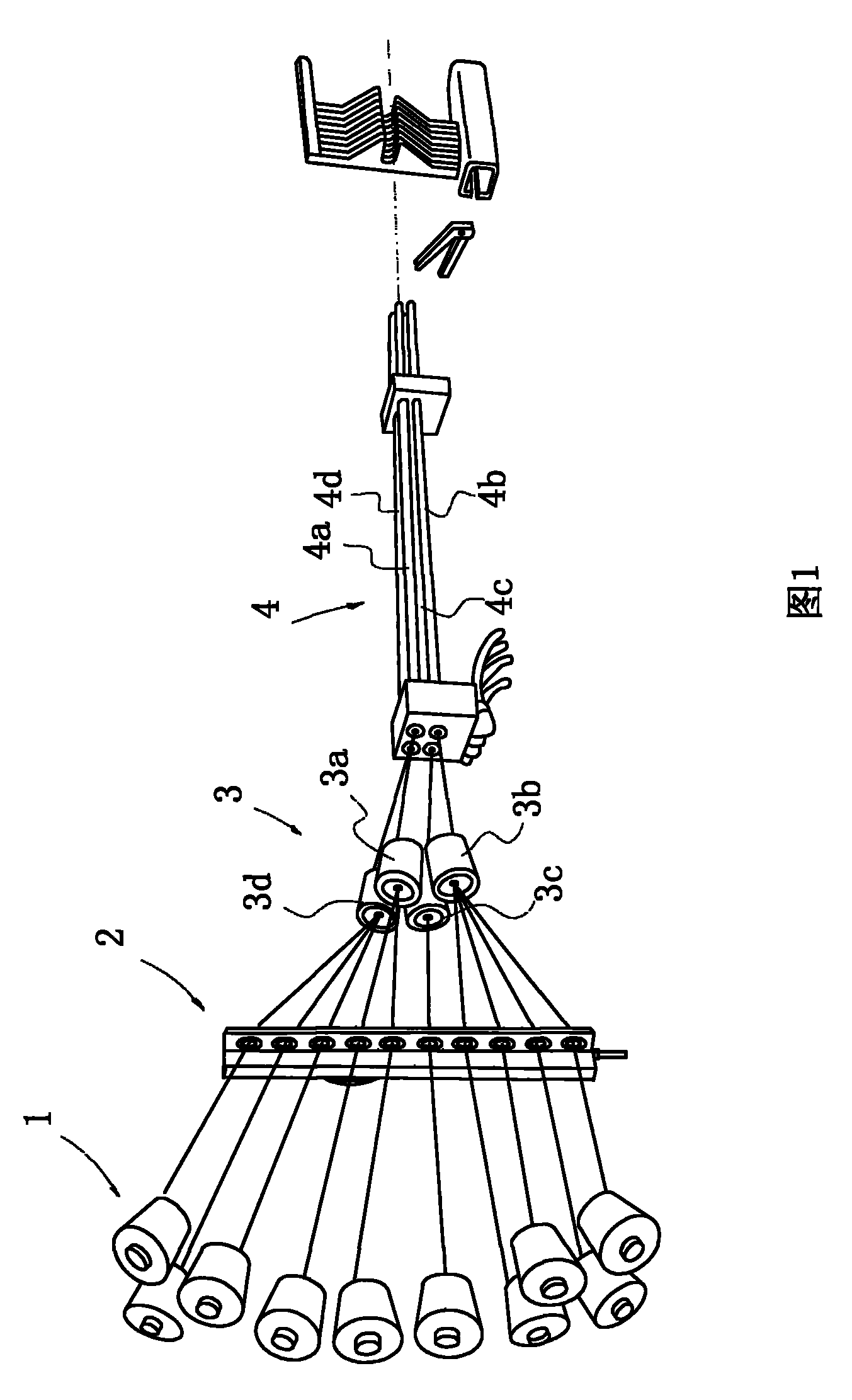

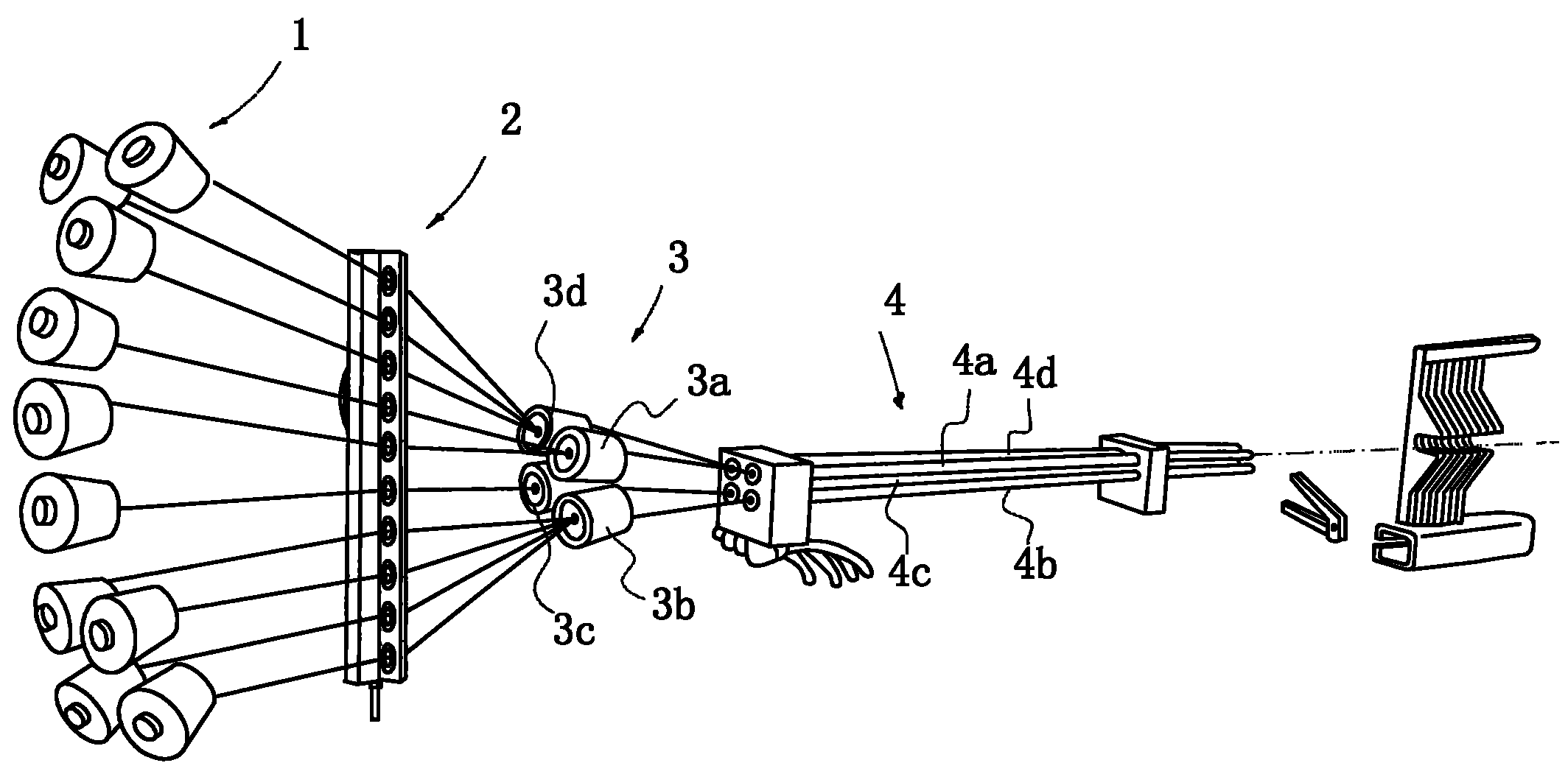

[0016] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

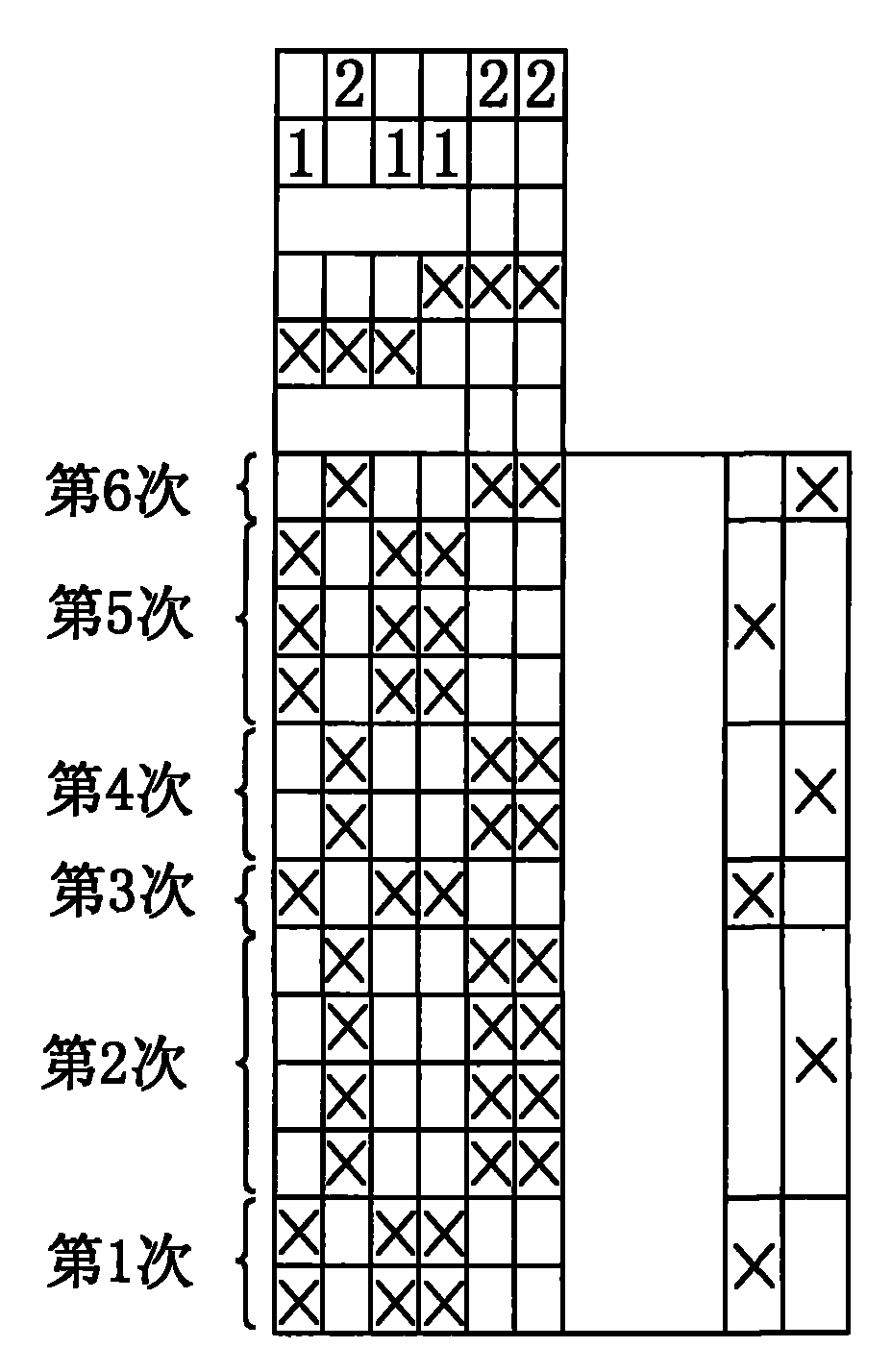

[0017] A variable warp-heavy-flat fabric is based on plain weave fabric, and is obtained by extending different weave points along the warp direction to obtain floating lengths with different lengths. The fabric specification of this embodiment: JC80 S ×80 S 220×180 63″(JC7.38×7.38 866.1×354.3 160cm), the fabric structure is Changes are rebalanced.

[0018] In this embodiment, the plain weave cam mechanism and the four-color weft-supply air-jet loom with variable weft density electronic take-up and electronic warp let-off devices are used for weaving. The let-off amount and take-up amount of the loom change according to the set rule, and in accordance with the change of the let-off amount and the take-up amount, each opening is introduced according to the set weft insertion sequence, and the corresponding weft yarns of different numbers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com