Engine reverse turning-proof method and system

An engine, anti-reverse technology, applied in the direction of engine components, engine ignition, machine/engine, etc., can solve problems such as engine damage, increase engine cost, unsuitable application, etc., to prevent work and ensure safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The engine anti-rotation method and system proposed by the present invention are described as follows in conjunction with the accompanying drawings and embodiments.

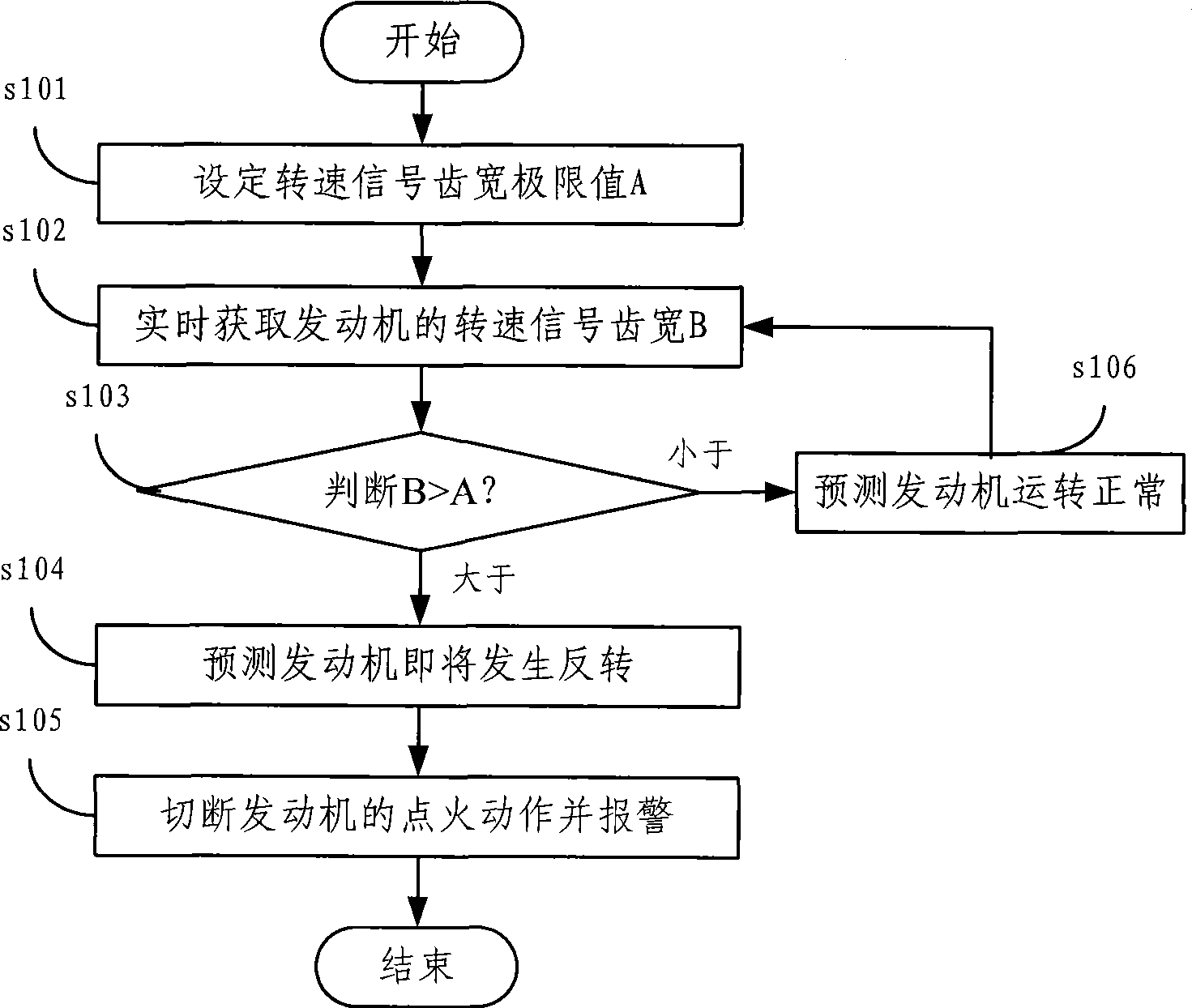

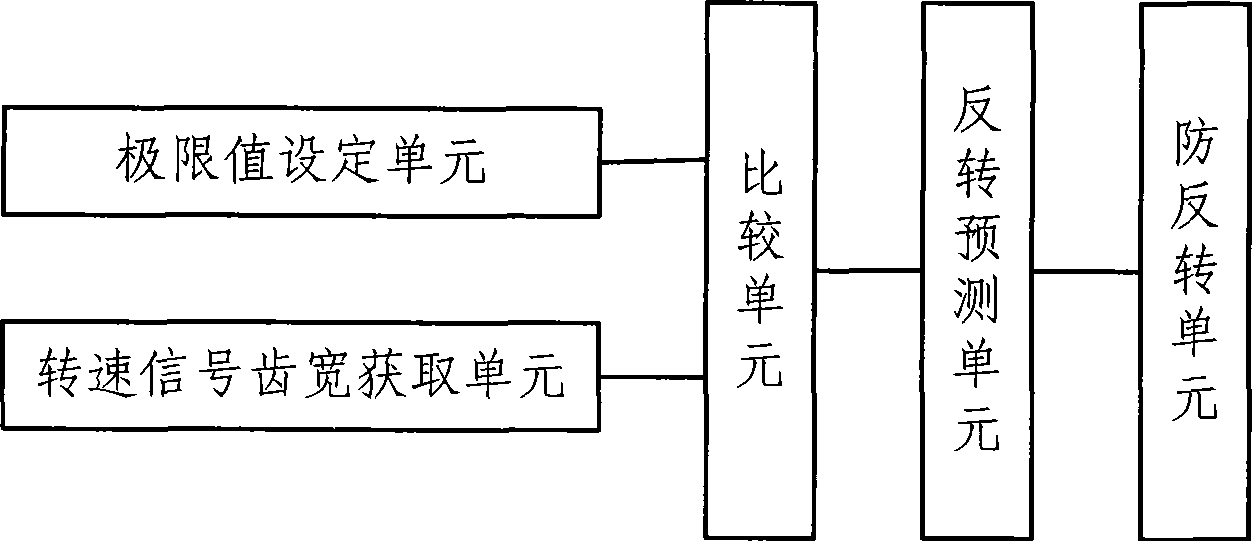

[0029] The applicable object of the present invention is exactly common type single-cylinder engine, and this engine just is applied on the motorcycle in current situation. Such as figure 1 Shown is the flow chart of the engine anti-reverse method of the present invention, the method includes the following steps: s101, setting the speed signal tooth width limit value A as a reference for judging whether the engine will reverse; s102, during the engine running process Obtain the speed signal tooth width B of the engine in real time; s103, judge whether the speed signal tooth width B is greater than the speed signal tooth width limit value A, if greater, execute step s104, otherwise, execute step s106; s104, predict that the reverse will occur, execute Step s105; s105, cut off the ignition of the engine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com