Antibacterial nose pad preparation method and nose pad

A production method and technology of nose pads, which are applied in the direction of instruments, glasses/goggles, optics, etc., can solve the problems of reducing the service life of nose pads, discoloration of nose pads, and oily nose pad materials, so as to protect human health and have good antibacterial properties And anti-mildew, to ensure the effect of safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

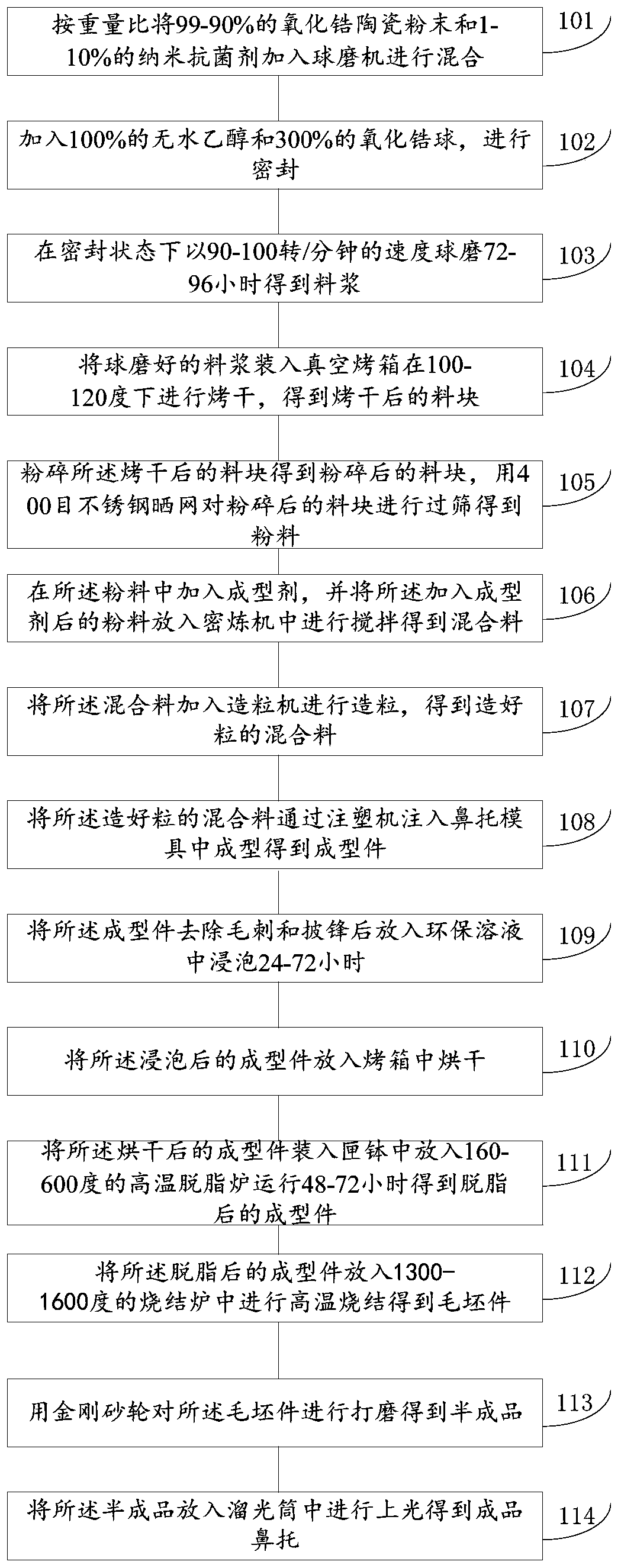

[0038] Ceramic products are environmentally friendly because of their materials, and have the characteristics of high strength, high hardness, wear resistance, corrosion resistance, oxidation resistance, light weight, hygiene, and aesthetics. Anti-mildew effect, the embodiment of the present application uses ceramics as the main preparation material of the nose pads. Before this application, the applicant once proposed to add negative ions into the nose pad material as a raw material. The negative ions can purify the air and promote blood circulation, but the antibacterial effect is not good. In view of this, the applicant A new antibacterial nose pad preparation method is proposed to solve the problems in the prior art, such as figure 1 shown, including the following steps:

[0039] Step 101: adding 99-90% zirconia ceramic powder and 1-10% nanometer antibacterial agent into a ball mill for mixing by weight;

[0040] In order to enhance the hardness of the nose pads and incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com