Network coordinative production scheduling system based on Virtual-Hub and self-adapting scheduling method thereof

A network collaboration and production scheduling technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve problems such as undiscovered invention patents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the content of the present invention and the embodiments described in the accompanying drawings.

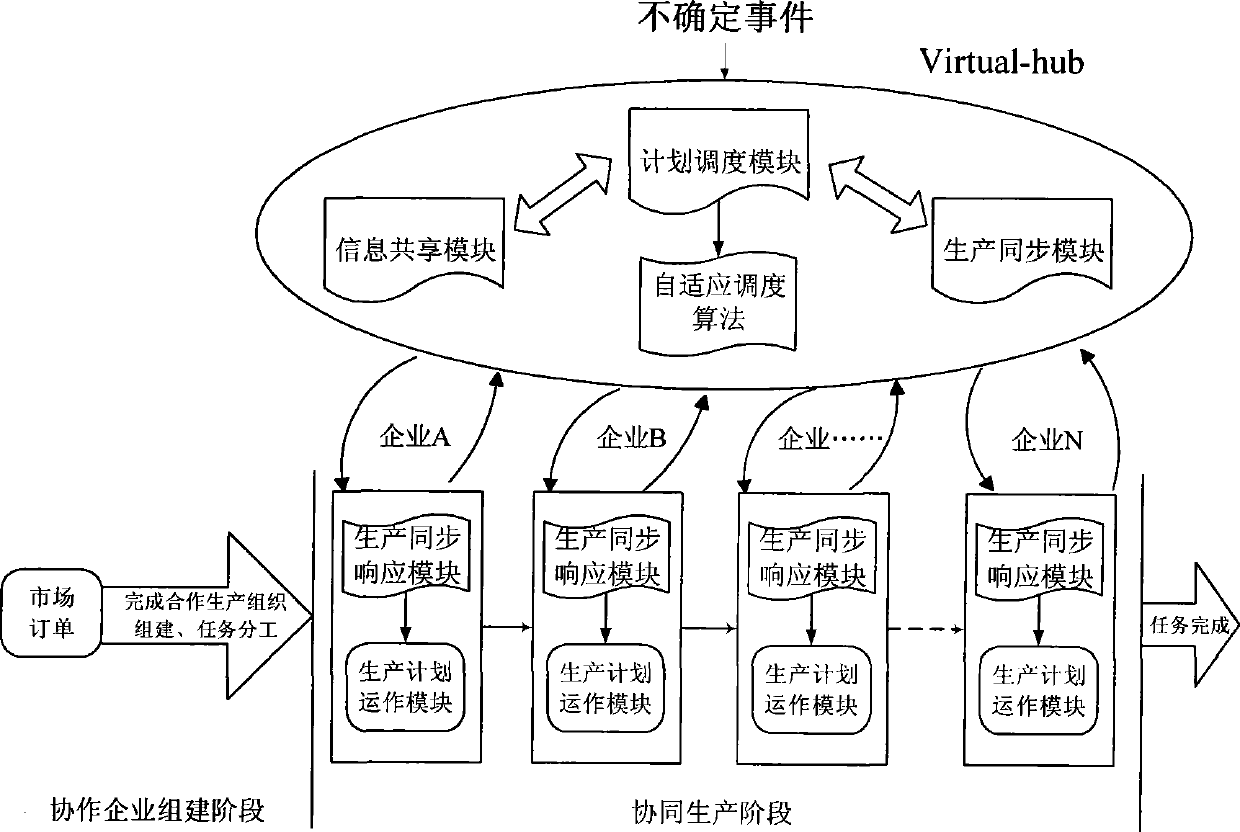

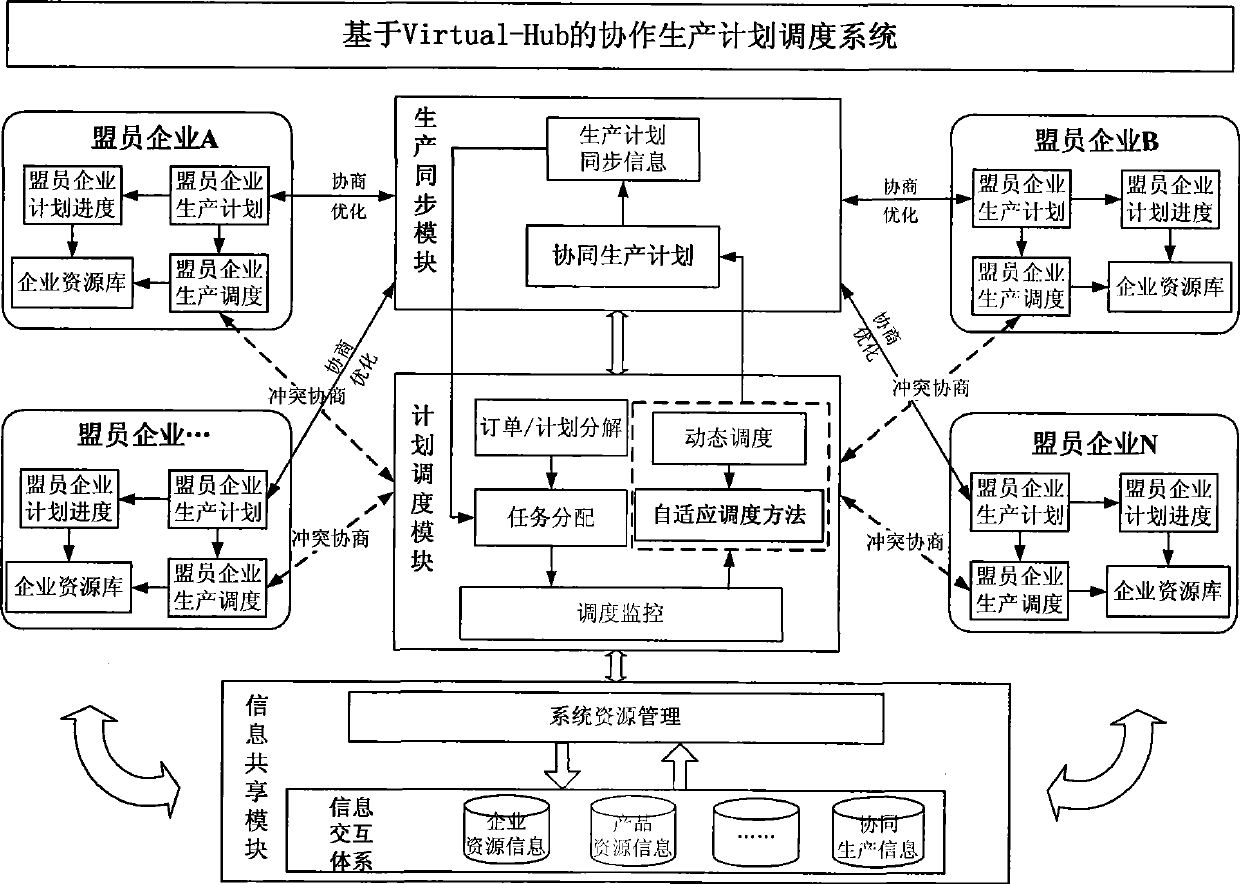

[0057] The present invention provides a network collaborative production scheduling system based on Virtual-Hub, its structure is as follows figure 1 shown. The network collaborative production scheduling system based on Virtual-Hub is a network virtual platform that can be accessed through standard Web protocols (HTTP, WSDL) and Servelet engine.

[0058] The system adopts B / S structure in the overall structure, and mainly adopts J2EE technology with strong portability, HTML, JSP (Java Service Pages), XML and Web Service technology in the system construction. At the same time, according to the characteristics of the system, the relatively mature open source frameworks such as Hibernate, Struts, Spring and ibatis and JFreeChart drawing components are adopted. The server side uses JSP technology to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com