Method of shutting down a high pressure discharge lamp and driving unit for driving a high pressure discharge lamp

A technology for high-pressure discharge lamps and drive units, applied in the field of projector systems and drive units for driving high-pressure discharge lamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The dimensions of objects in the drawings are chosen for clarity and do not necessarily reflect actual relative dimensions.

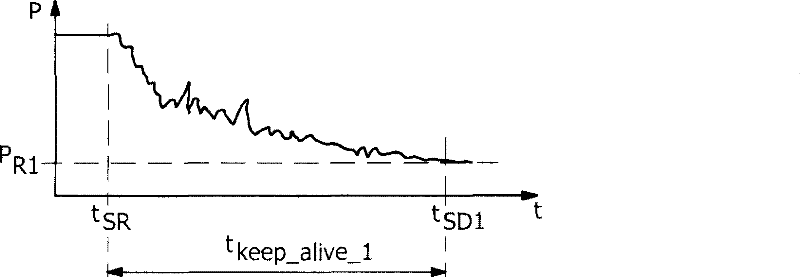

[0037] exist Figure 1-2 A possible sequence of actions for switching off a mercury vapor discharge lamp is described in . It is self-evident that the values mentioned in connection with these explicit courses of action are purely exemplary and relate, without limiting the generality of the invention, to a lamp with a nominal power of 120 watts in normal lamp operation. Mercury vapor discharge lamps. Obviously, these values must be adjusted to suit whatever lamp or driver configuration is actually used.

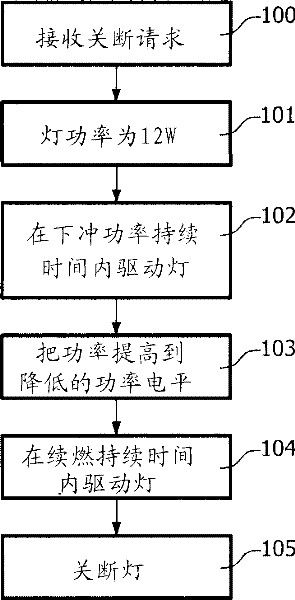

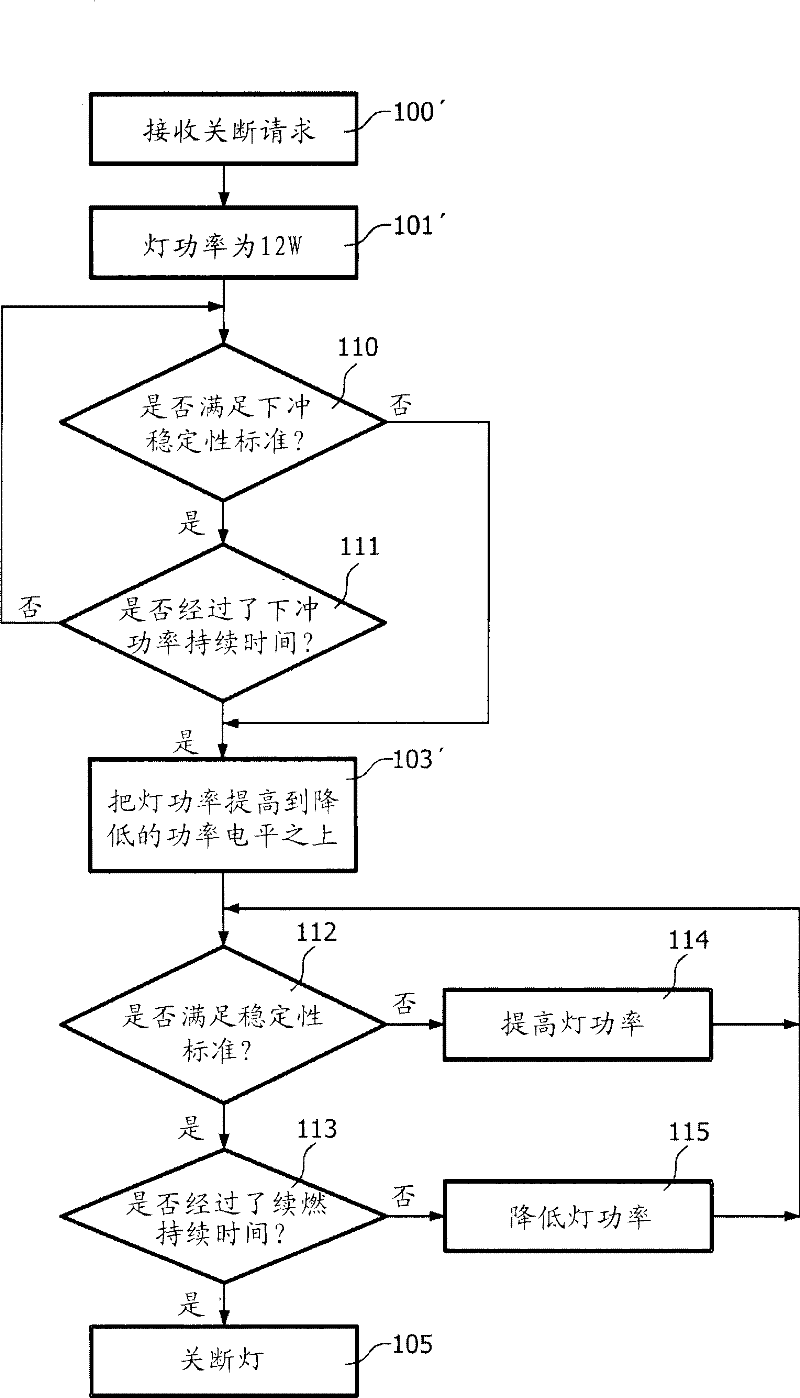

[0038] figure 1 The steps in a simple shutdown sequence are shown. In step 100 a shutdown request is received. Once the switch off request is received, the lamp power is abruptly reduced in step 101 to an undershoot power level of 10% of nominal power (which in this example is a level of 12W). In step 102, the lamp is driven at the und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com