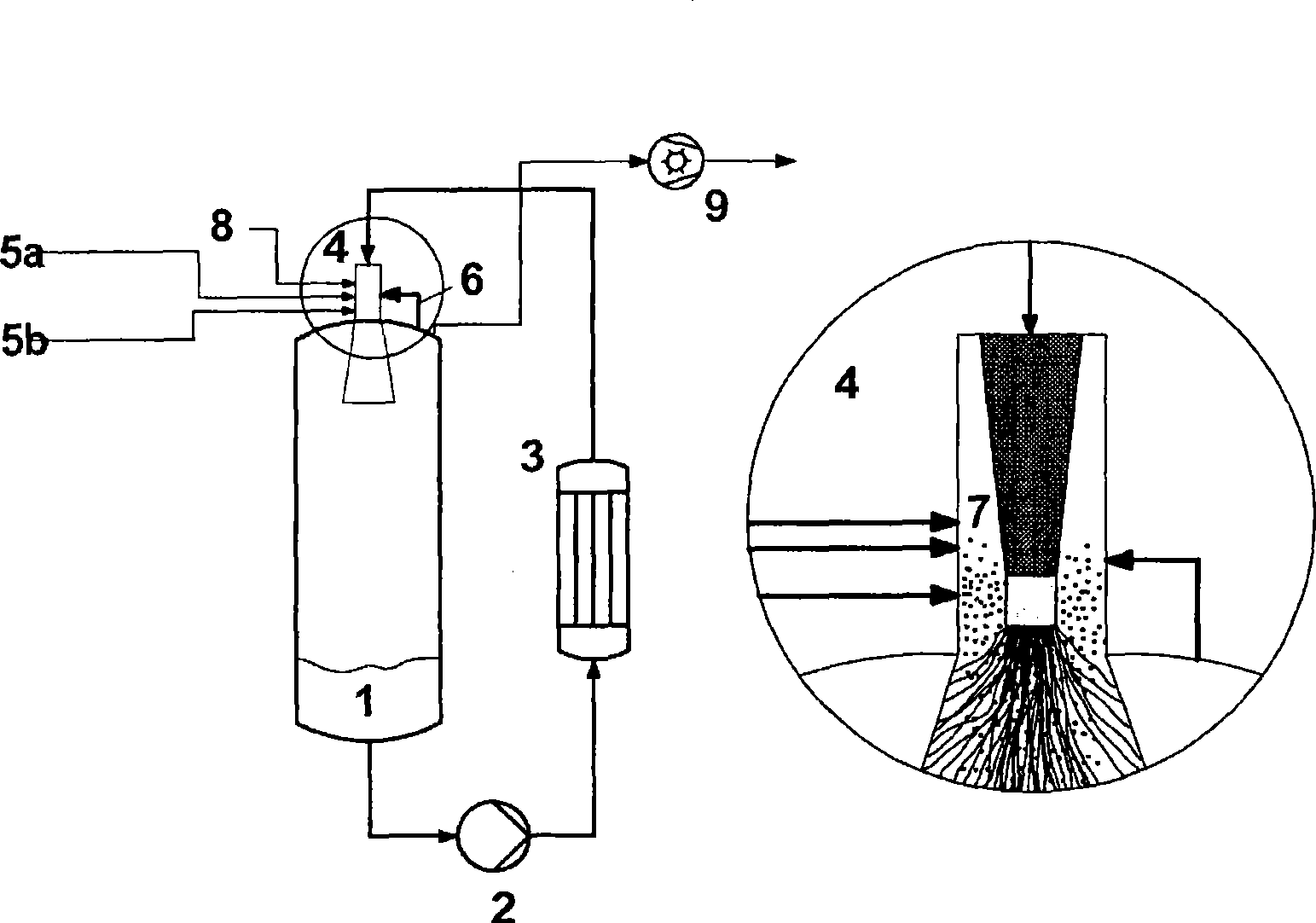

Method for alkoxylisation with DMC catalysts in loop-type bubble column with eductor

A DMC catalyst and loop reactor technology, applied in the field of alkoxylation, can solve the problems of narrowing and unfavorable molar mass distribution, and achieve the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

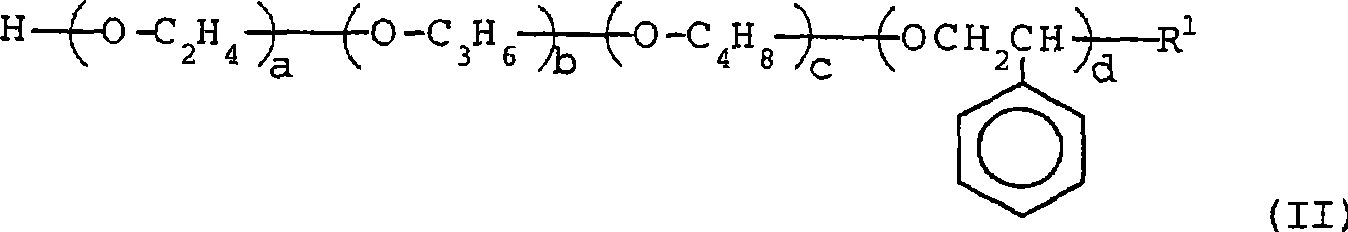

[0032] The method of the present invention will now be described by way of example, and these illustrative embodiments are not intended to limit the scope of the invention in any way. When hereinafter a range, formula or compound type is mentioned, it shall include not only the corresponding range or group of compounds explicitly mentioned, but also all sub-ranges which may be obtained by selection of individual values (ranges) or compounds and subclasses of Compound. When documents are cited in the context of this specification, the contents of said documents should be fully included in the disclosed content of the present invention. When the compounds described in the context of the present invention have different units that occur several times, the units may be distributed randomly (random oligomers) or in ordered form (block oligomers) in these compounds. )Appear. Statements relating to the number of units in a stated compound are to be understood as averages averaged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com