Combing machine with a reserve reel trough

A storage tank and combing machine technology, which is applied in the field of combing machines, can solve the problems of lifting heavy laps and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

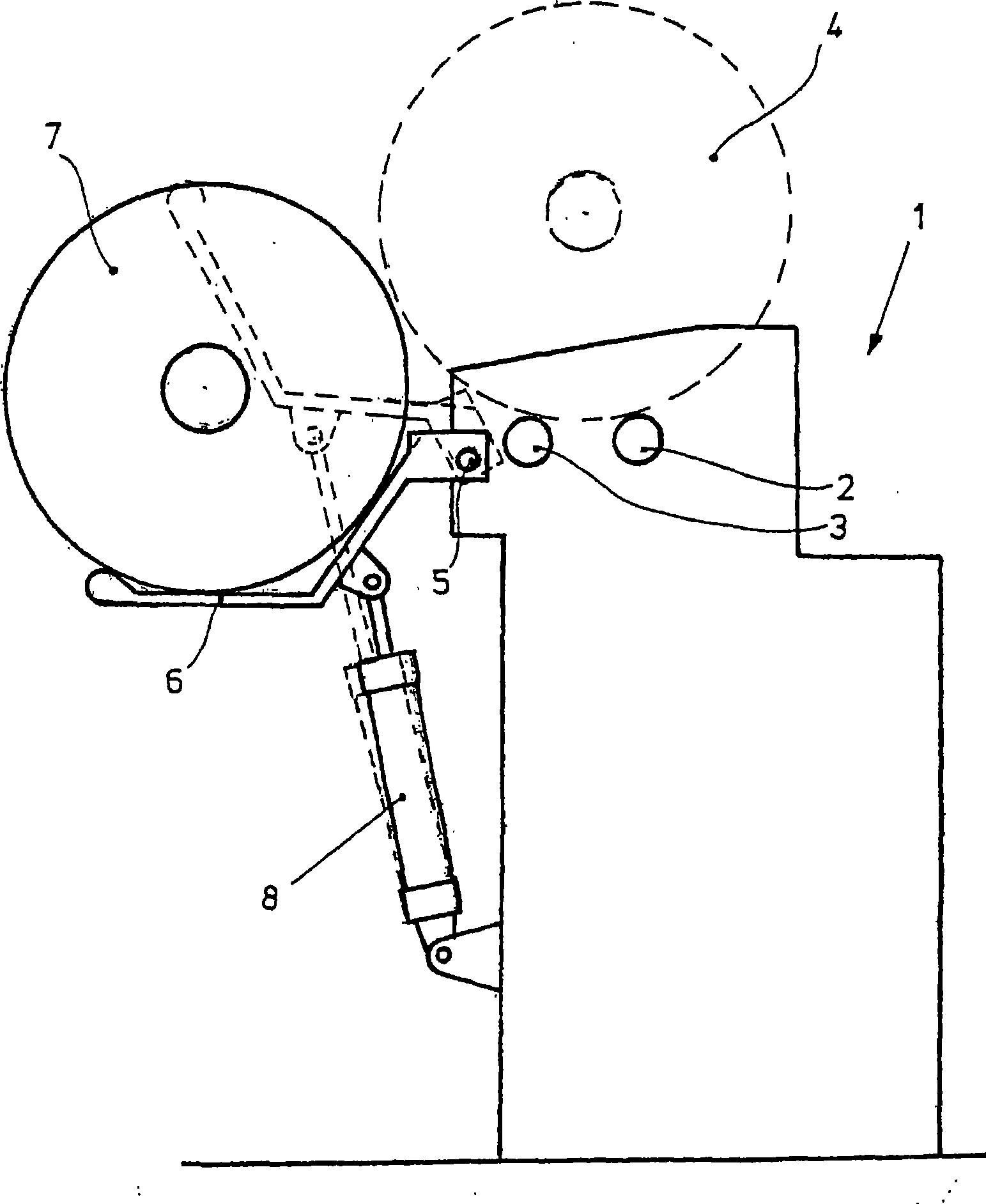

[0012] Only the outline of the frame of the comber 1 is shown. However, two winding rollers 2 and 3 are shown, on which a working lap 4 is placed and which is unwound while being fed to a not shown comber nipper arrangement .

[0013] On the back of the frame, a roll chute 6 in which a reserve roll 7 is stored is pivotally mounted on the pivot shaft 5 . The store lap rack is connected to an energy store, which is supported on the frame, here the energy store is the cylinder / piston unit 8 . The means for driving the cylinder / piston unit are not shown here. In common usage, these devices include pneumatic or hydraulic pressure sources and control slides.

[0014] When pressure is applied to the drive cylinder / piston unit 8 , the cylinder / piston unit 8 pivots the supply roll trough 6 upwards so that the supply roll located therein rolls onto the winding rollers 2 , 3 .

[0015] If it is desired to manually replace an unwound lap with a new lap, the pressurization of the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com