Hot-rolling supporting roll surface defect repair method

A defect repair and backup roll technology, applied in the field of hot-rolled backup roll surface defect repair, can solve the problems of large backup roll loss, long repair time, large roll consumption, etc. The effect of roller wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

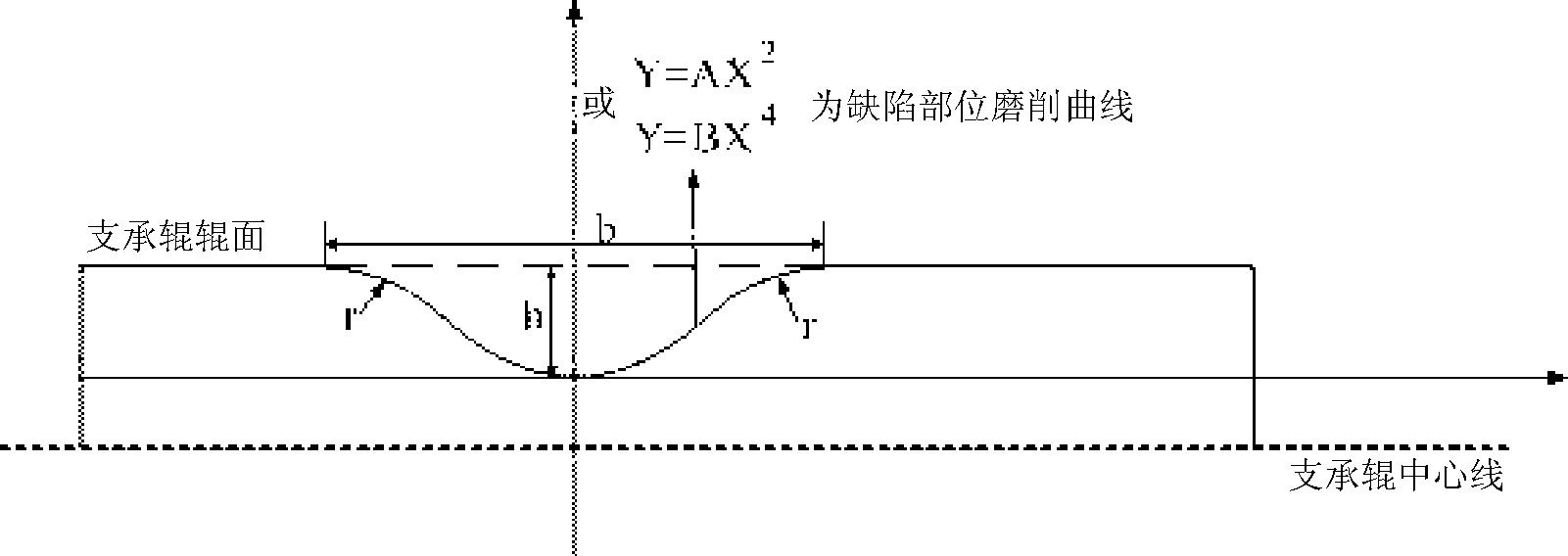

[0020] The core of the present invention is to only perform grinding and repair on local defective parts, and the diameter of the whole back-up roll remains unchanged after the repair, thereby reducing roll consumption, prolonging the service life of the back-up roll, and further increasing the production capacity of the rolling mill.

[0021] In this embodiment, the method for repairing surface defects of hot-rolled back-up rolls is carried out in the following steps:

[0022] 1. Determine the depth and area of the defect;

[0023] 2. Make holes on the defective parts and remove the defective metal layer from the roller surface;

[0024] 3. Check whether the defects are dealt with cleanly;

[0025] 4. Grind the hole and its surroundings to form a smooth surface; so far, the repair is completed.

[0026] Specifically, step 1 uses ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com