Dehumidifying container

A container and container body technology, which is applied in the field of dehumidification containers, can solve the problems of plastic moisture, etc., and achieve the effect of improving efficiency and ensuring yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The dehumidification container provided by the technical solution will be further described in detail below with reference to the accompanying drawings and embodiments.

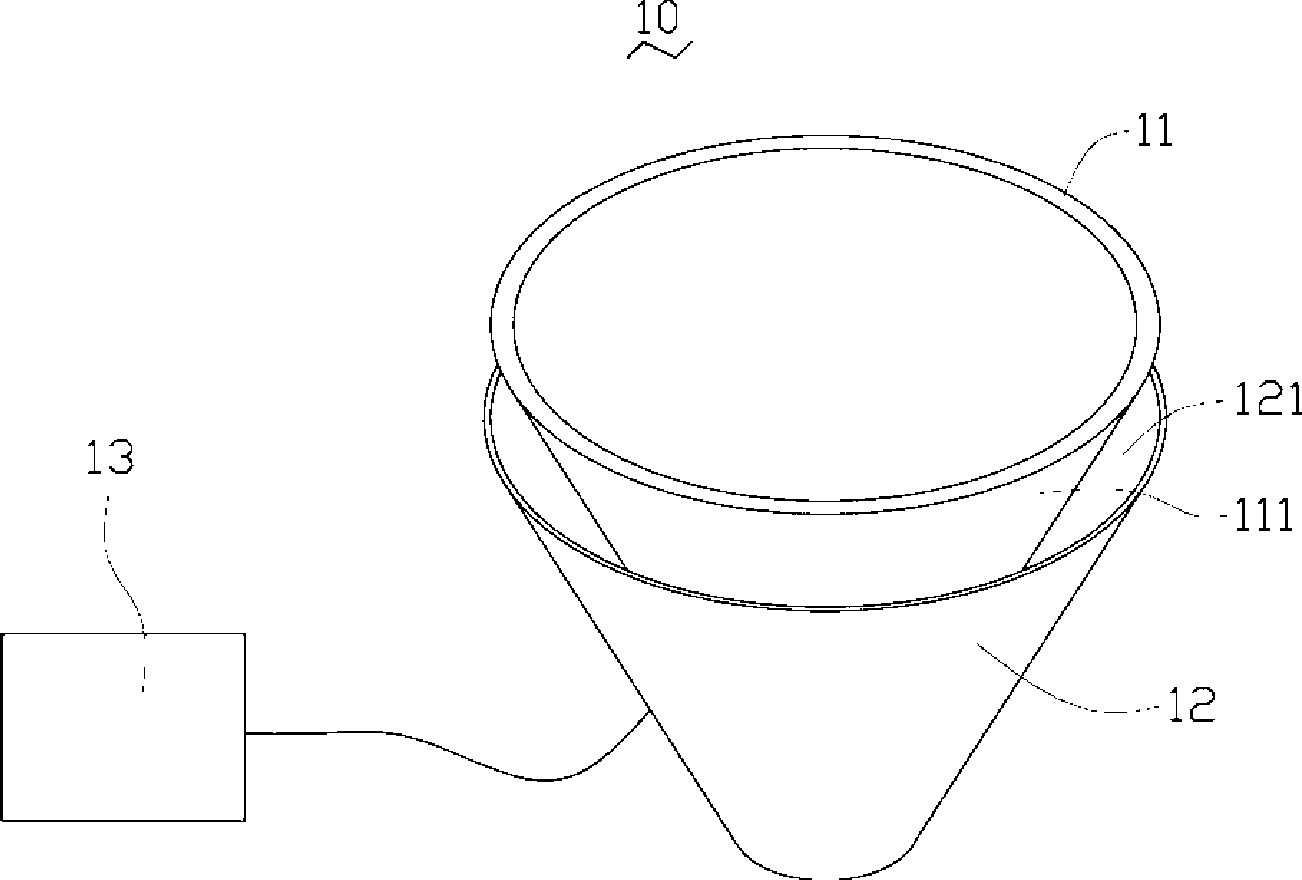

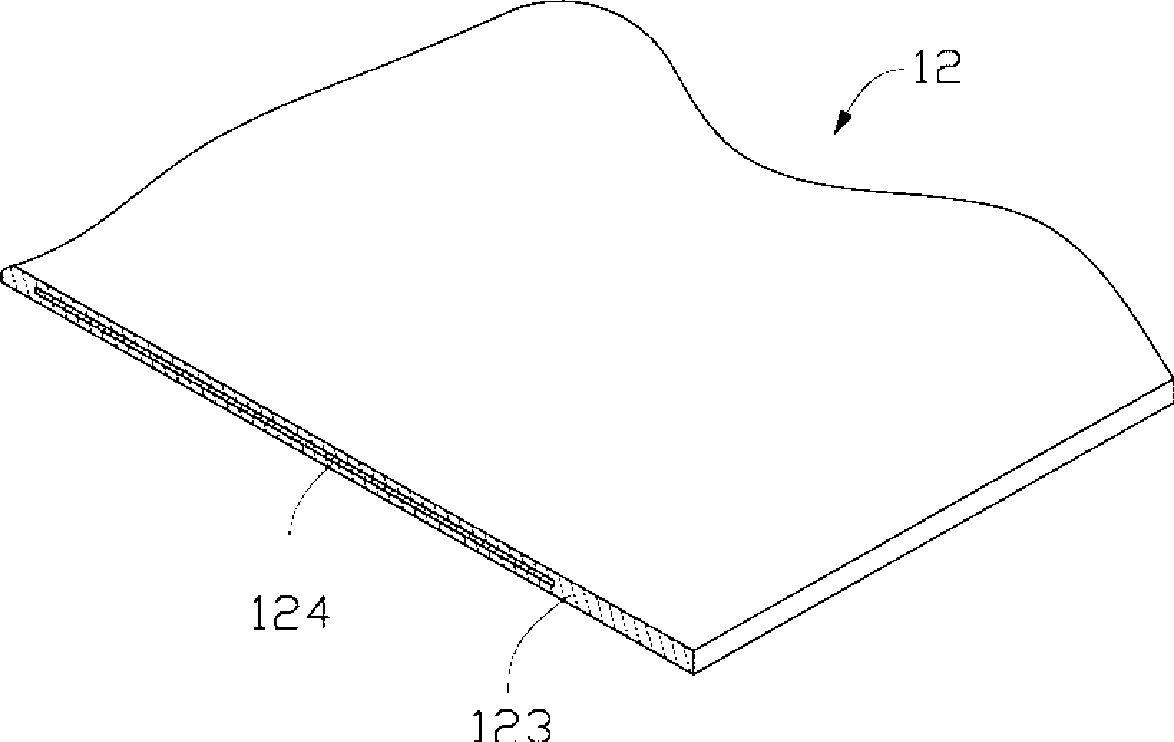

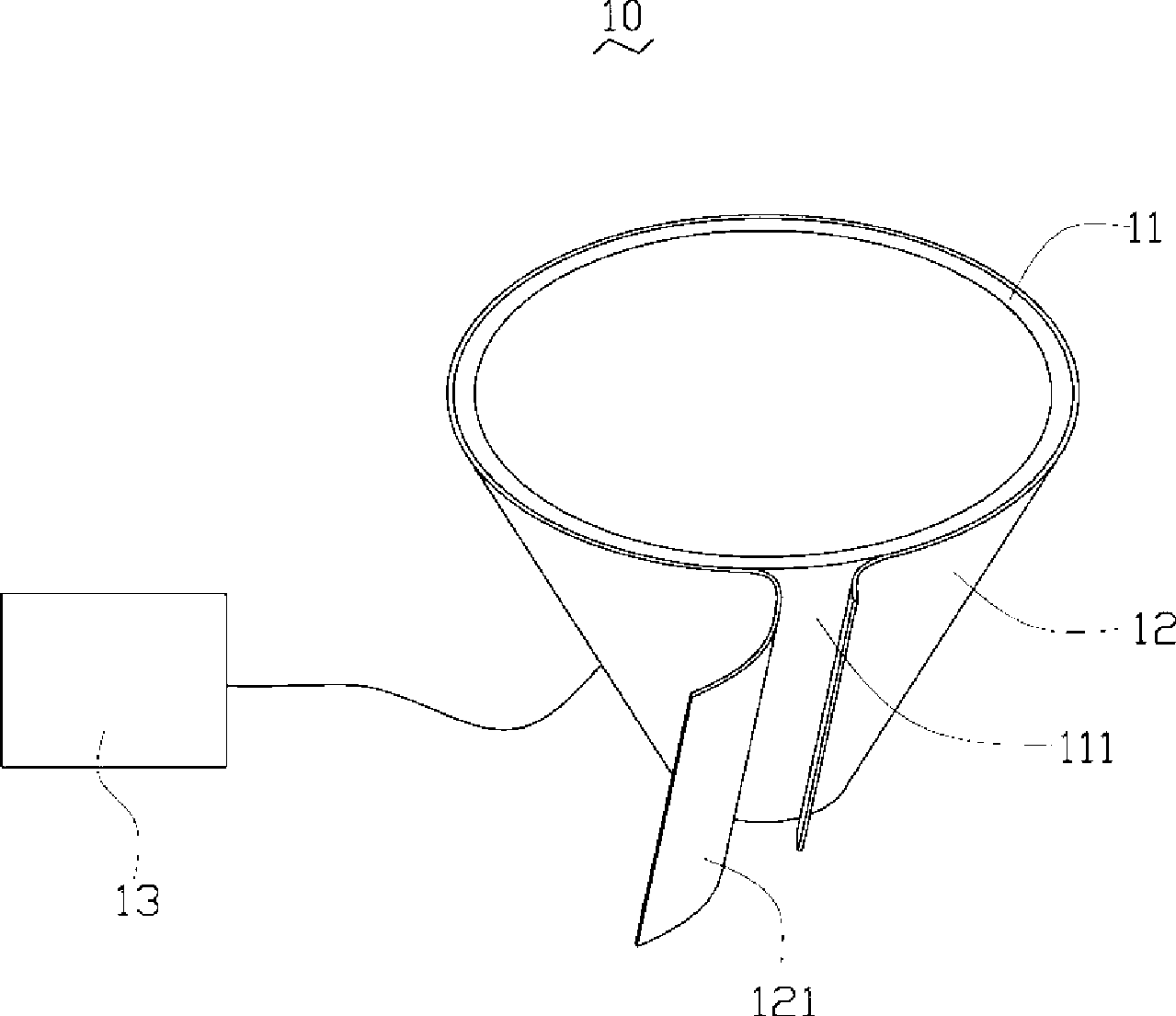

[0014] Please also refer to figure 1 , figure 2 and image 3 , which is the dehumidification container 10 provided by the first embodiment, which includes a container body 11 , a heating part 12 and a control part 13 .

[0015] The container body 11 is enclosed by a side wall 111 with good thermal conductivity, and is used for accommodating the material to be dehumidified (not shown). In this embodiment, the container body 11 is a conical hopper made of iron, and has a feeding port and a discharging port (not shown in the figure), which can be installed in the injection machine for feeding. Of course, the container body 11 can also be a cylinder, a sphere or other shapes. In addition, the container body 11 can also be made of metal materials with good thermal conductivity, such as iron alloys, cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com