Drainage equipment of phosphorus waste liquid from phosphorus oxytrichloride process and use method thereof

A technology for waste liquid discharge, phosphorus oxychloride, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problem of increasing equipment maintenance time, blocking phosphorus waste liquid discharge, and frequent exchange of quartz collector components. In order to achieve the effect of low cost, reduced emission frequency and short maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

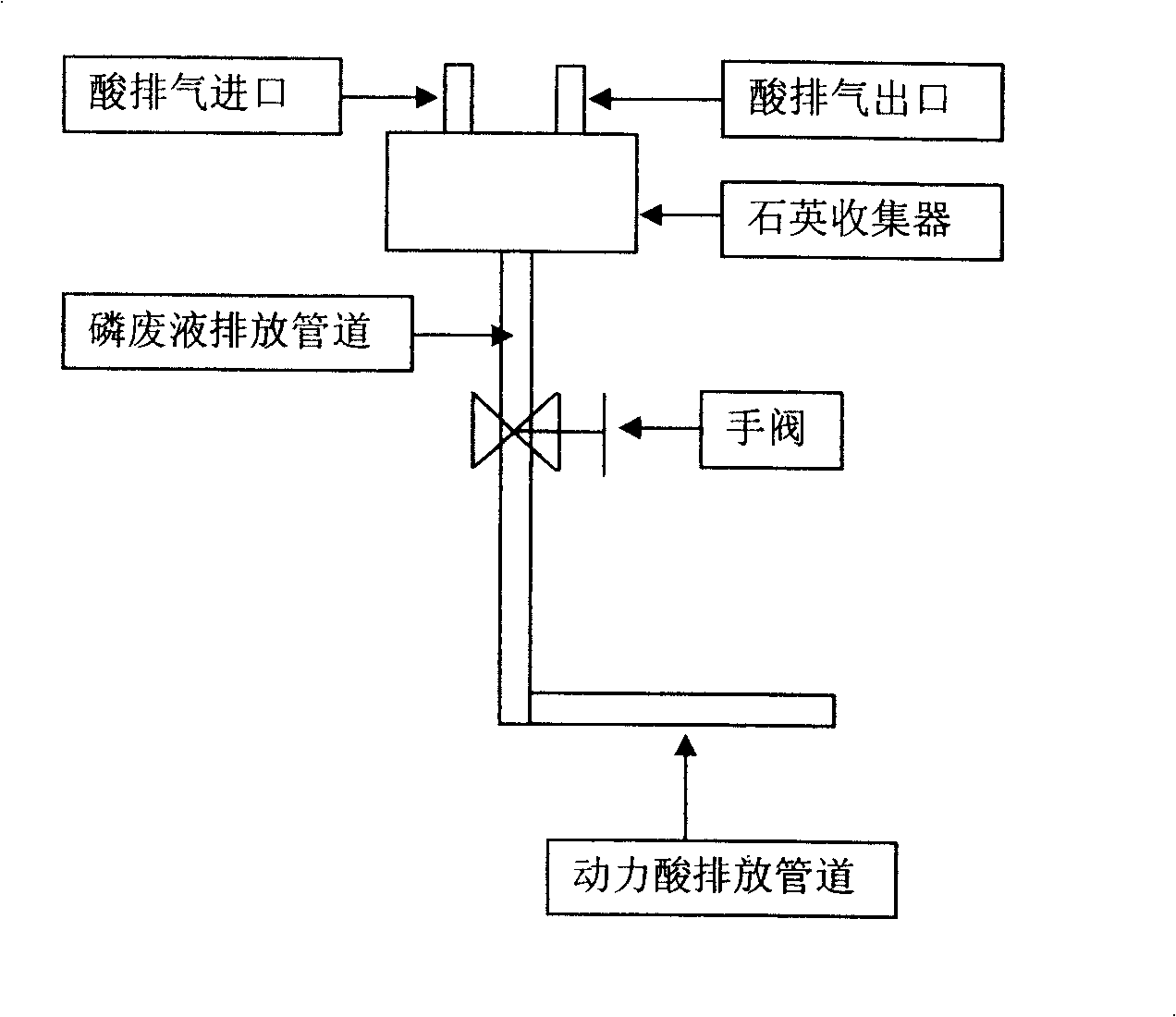

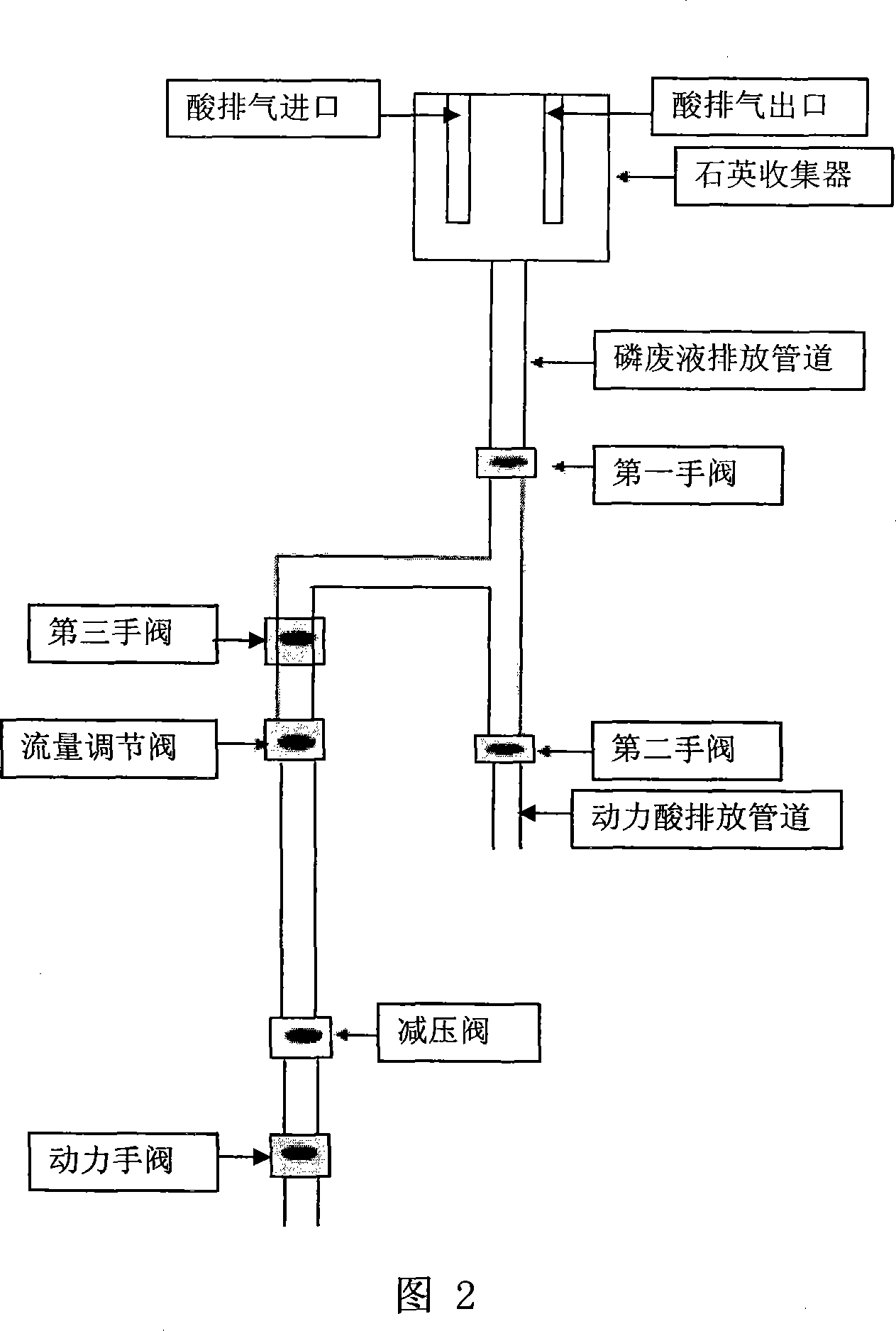

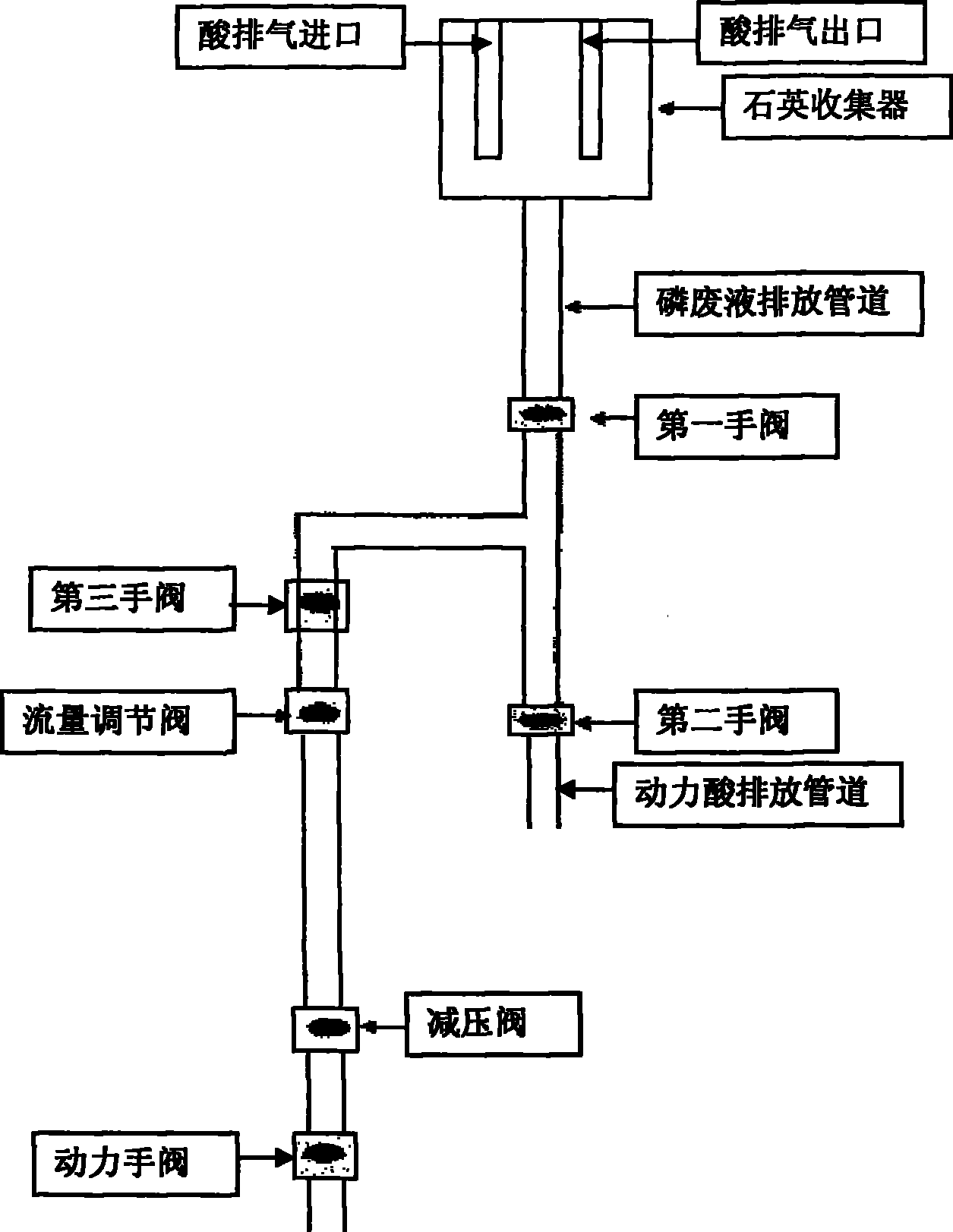

[0025] Such as figure 2 As shown, the discharge device of phosphorus oxychloride process phosphorus waste liquid of the present invention comprises quartz collector, phosphorus waste liquid discharge pipeline, power acid discharge pipeline, and one end of described phosphorus waste liquid discharge pipeline is connected with quartz collector, and the other end Connected with the power acid discharge pipeline, the quartz collector is provided with an acid exhaust inlet and an acid exhaust outlet, and the acid exhaust outlet is connected with the acid exhaust pipeline, and also includes:

[0026] The first-hand valve is set on the phosphorus waste liquid discharge pipeline to control the discharge of phosphorus waste liquid. When the phosphorus oxychloride process reaction is in progress, the first-hand valve is closed to isolate the acid exhaust pipe from the power acid discharge pipe. , so that the pressure in the quartz collector is stable and the acid exhaust works normally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com