Hollow carcass for filling cast-in-situ concrete

A hollow carcass, cast-in-place concrete technology, which is applied to floors, building materials, building components, etc., can solve the problems of low production efficiency, high cost, inconvenient production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

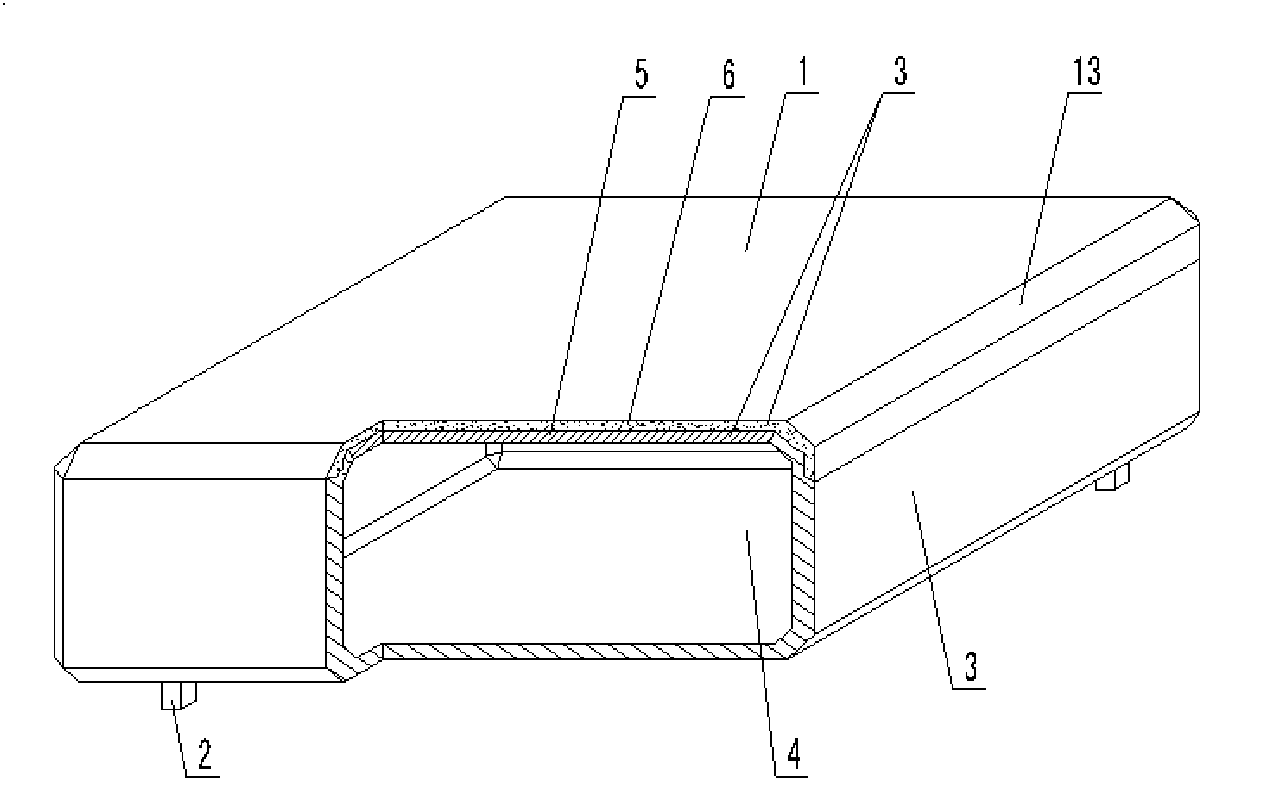

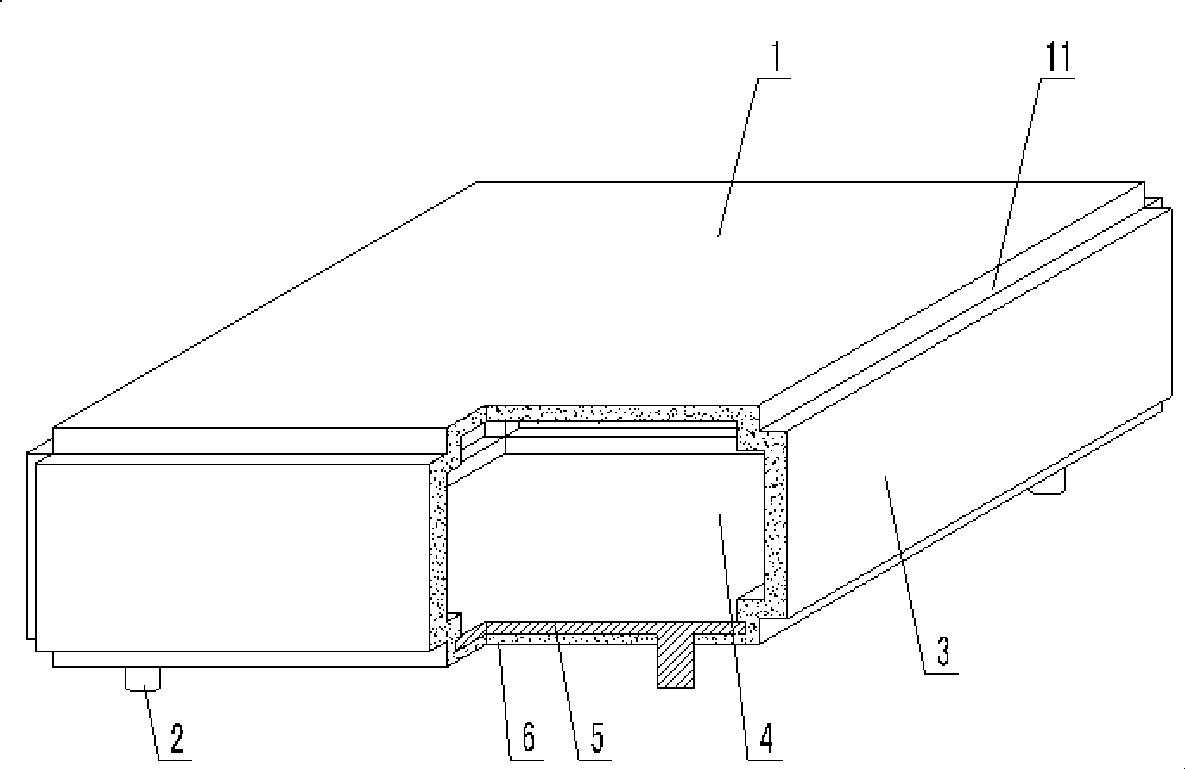

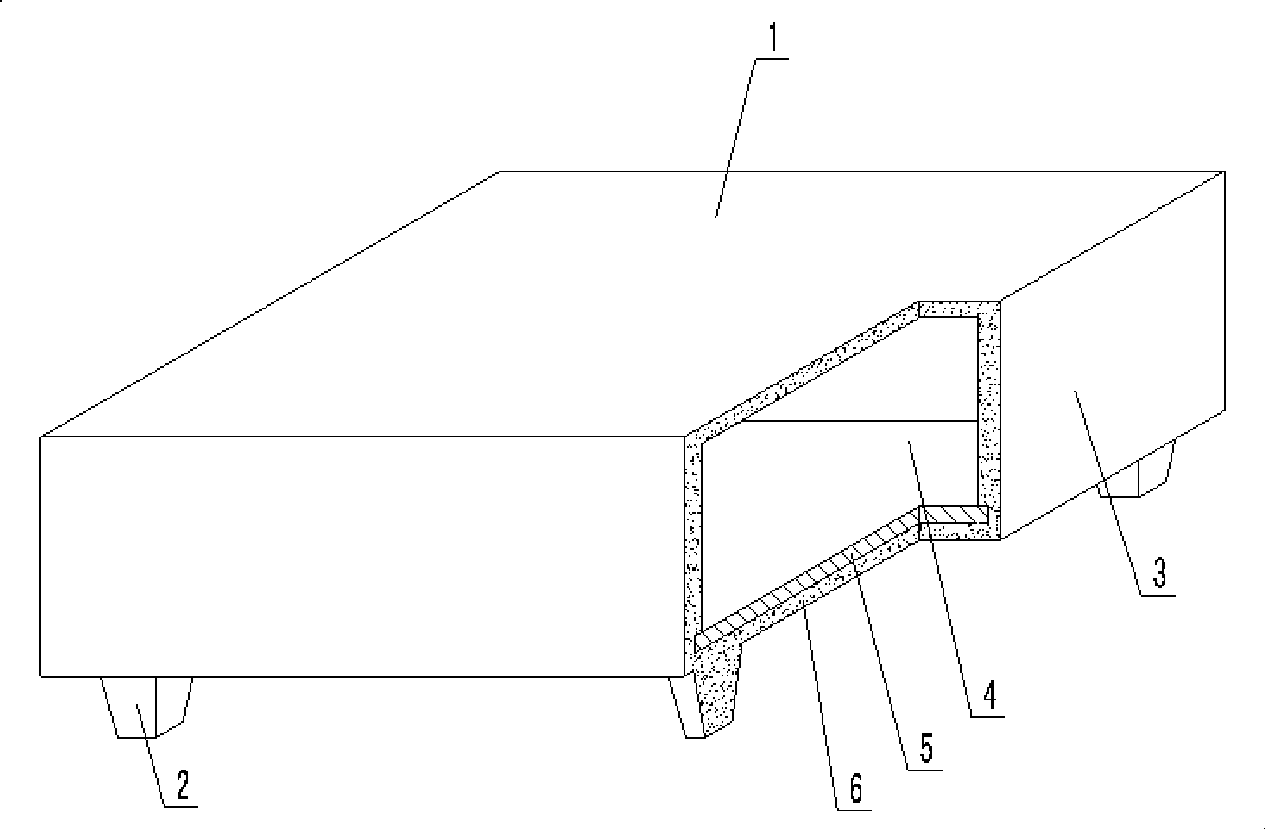

[0071] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0072] As shown in the accompanying drawings, the present invention includes a hollow carcass 1, a support foot 2, and an outer wall 3 enclosing the hollow carcass 1 with a cavity 4. It is characterized in that at least one outer wall 3 is an outer wall of a laminated layer. The prefabricated layer 5 in the laminated layer is arranged on the inner layer of the outer wall 3, the outer layer of the outer wall 3 is the freshly plastered layer 6, the upper outer wall 3 or the lower outer wall 3 is the outer wall of the laminated layer, and the cavity 4 is provided with a reinforcement 17 to strengthen Part 17 is a prefabricated hollow rod, and the two ports of the hollow rod communicate with the outside of the upper and lower outer walls 3 to form a connected hole 16. In each accompanying drawing, 1 is a hollow carcass, 2 is a support foot, 3 is an outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com