High precision cylinder helical compression spring squareness detecting method

A compression spring and perpendicularity technology, which is applied in the field of detection of the verticality of high-precision cylindrical helical compression springs, can solve problems affecting the adjustment of flow or pressure, failure to meet the use requirements, adjustment fluctuations of fuel flow or gas pressure, etc., to achieve The effect of improving quality standards, enriching production methods, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

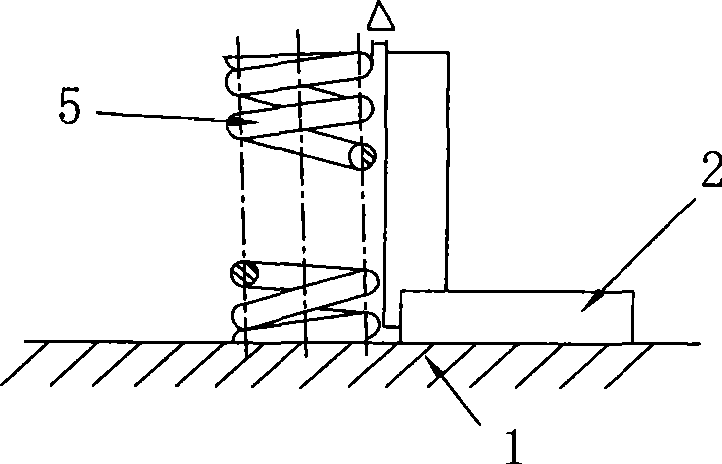

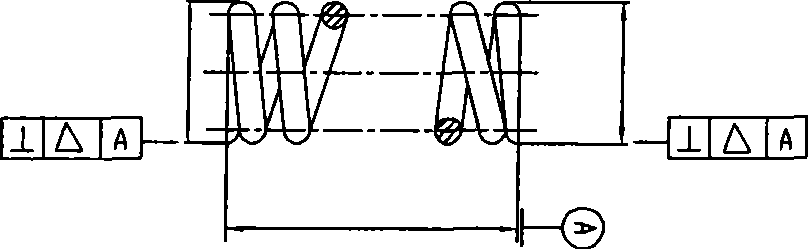

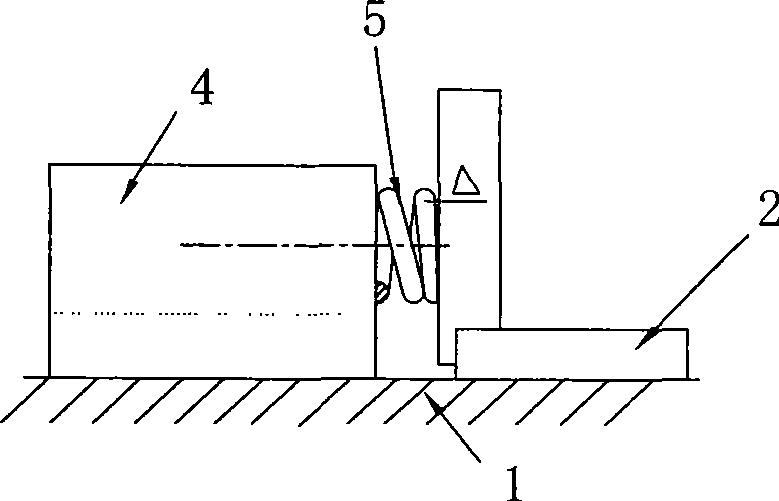

[0014] Such as Figure 3-5 As shown, the detection method of a high-precision cylindrical spiral compression spring, the detection steps are: a. Place a high-precision wide-seat square 2 and a spring placement frame 4 with a horizontal V-shaped groove 3 on the 0-level platform 1. , Make the wide seat square 2 and the horizontal V-groove 3 of the spring placement frame 4 directly face; b. In the unloaded state (ie free state) of the tested compression spring 5, place the tested compression spring 5 horizontally on the spring The horizontal direction of the frame is in the V-shaped groove 3, and the end surface of the tested compression spring 5 is pressed against the wide seat square 2, and the tested compression spring 5 is rotated once. While rotating, measure the end surface of the tested compression spring 5 The distance between the wide seat squares 2 is the maximum value as the perpendicularity deviation △ of the end face of the tested compression spring 5; flip the tested com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com