Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., to eliminate poor rigidity and improve uneven wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

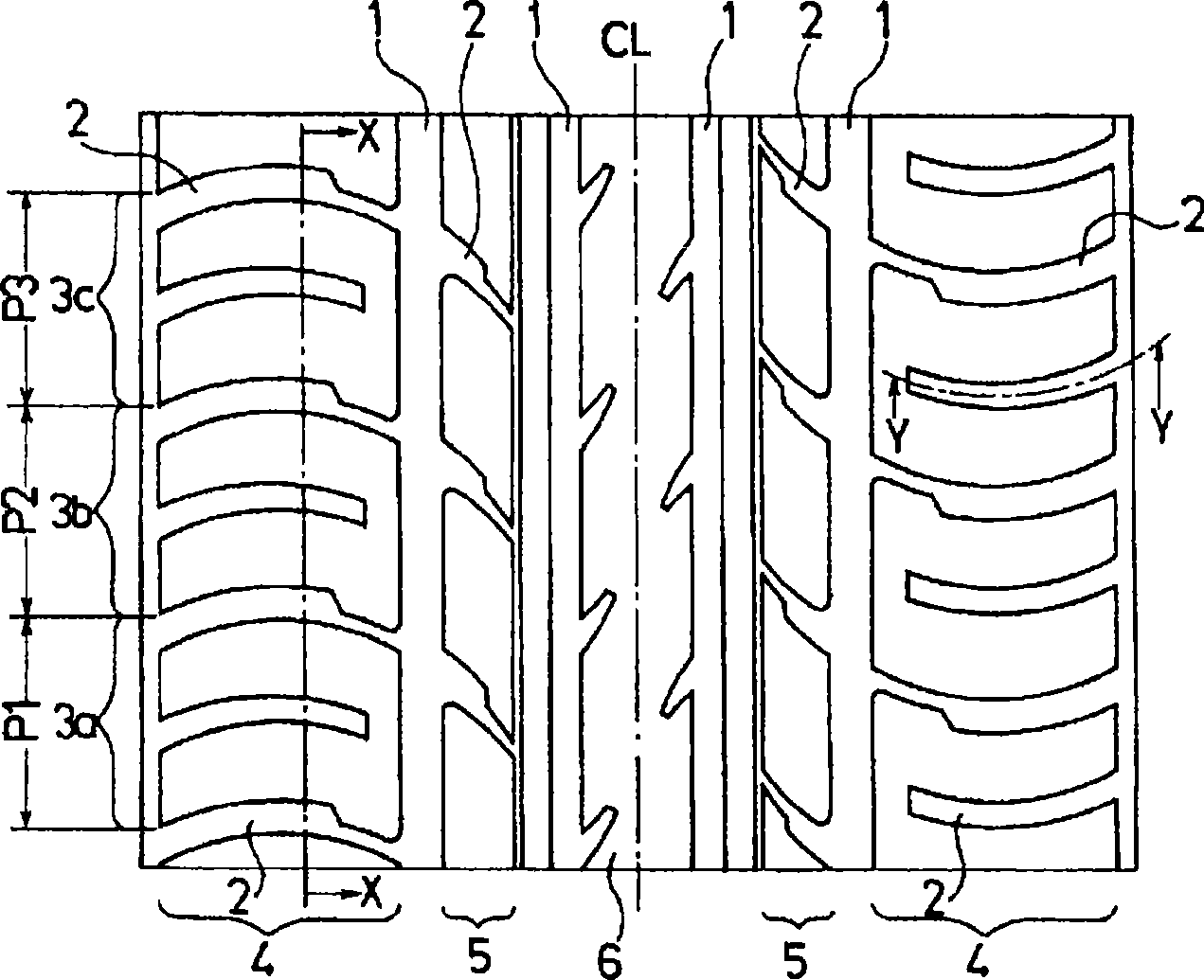

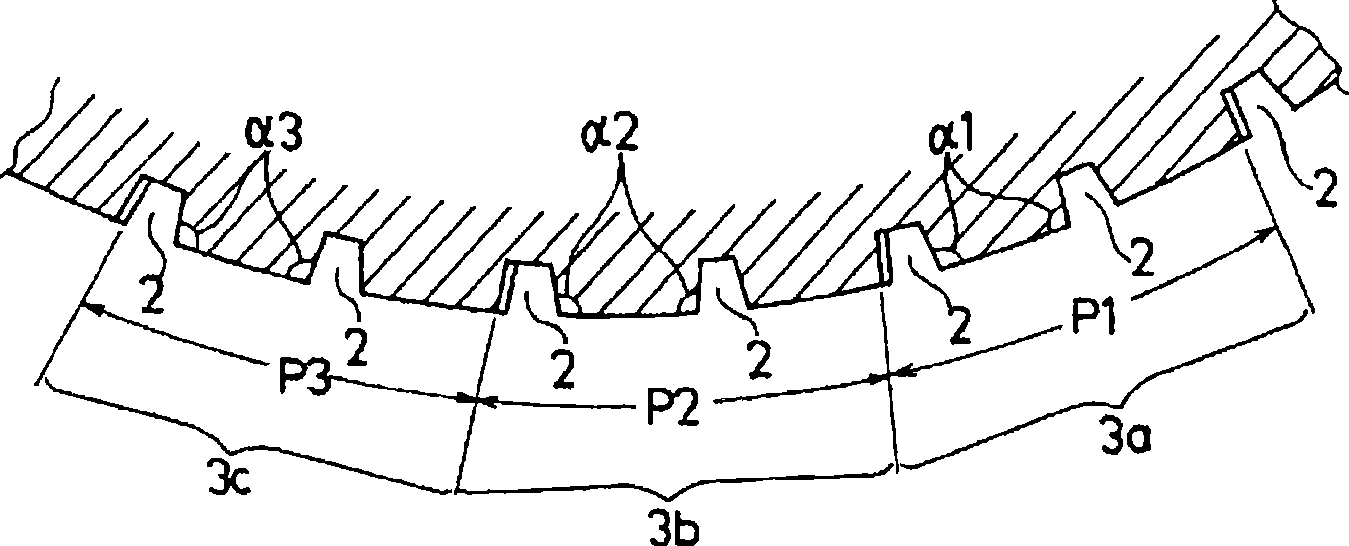

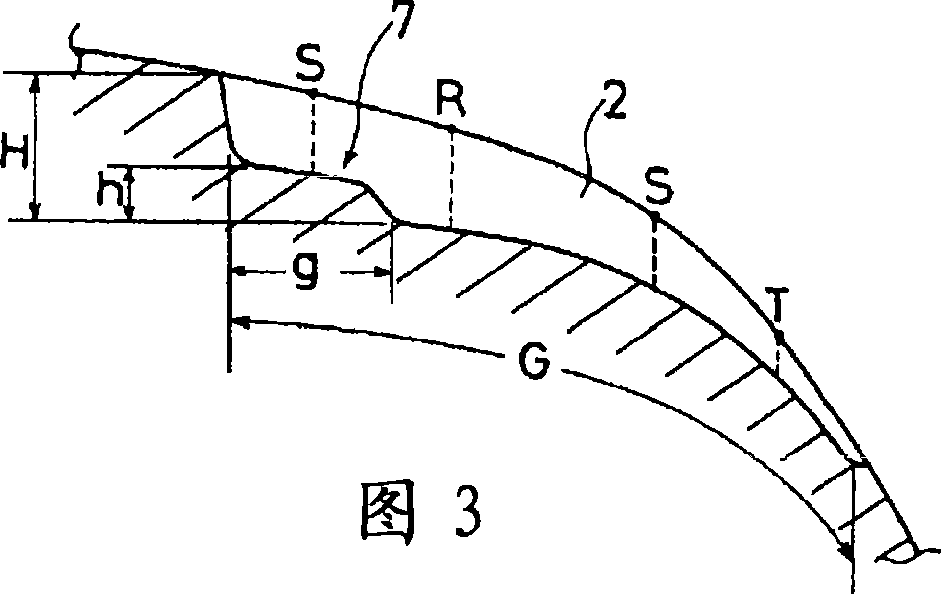

[0046] 20 comparative tires (comparative examples 1 and 2) and tires of the present invention (embodiments 1 to 3) were produced respectively, wherein: the tire size was set to 275 / 35R20 and the tread pattern was set to figure 1 Thus, the ratio of the groove area for each pitch and the groove wall angle α on the side of the obtuse angle formed by the groove wall of the lateral groove and the tangential direction of the tread surface were varied as shown in Table 1. In addition, in each tire, the pitch lengths P1, P2, and P3 of the three types of pitches were set to P1 (large pitch 3a) = 40mm, P2 (intermediate pitch 3b) = 35mm, and P3 (small pitch) = 30mm.

[0047] For the above five types of tires, uniformity (RFV: Radial Force Variation) was measured in accordance with JIS (Japanese Industrial Standards: Japanese Industrial Standards) D4233, and the number of tires with the reference value (108N) cleared The evaluation of the uniformity was performed, and the results are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com