Refueling container

A fuel supply and container technology, applied in fuel cell additives, packaging, transportation and packaging, etc., can solve problems such as fuel deterioration, shedding, and narrowing of the selection range of component materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0088] First, a first embodiment of the refueling container of the present invention will be described.

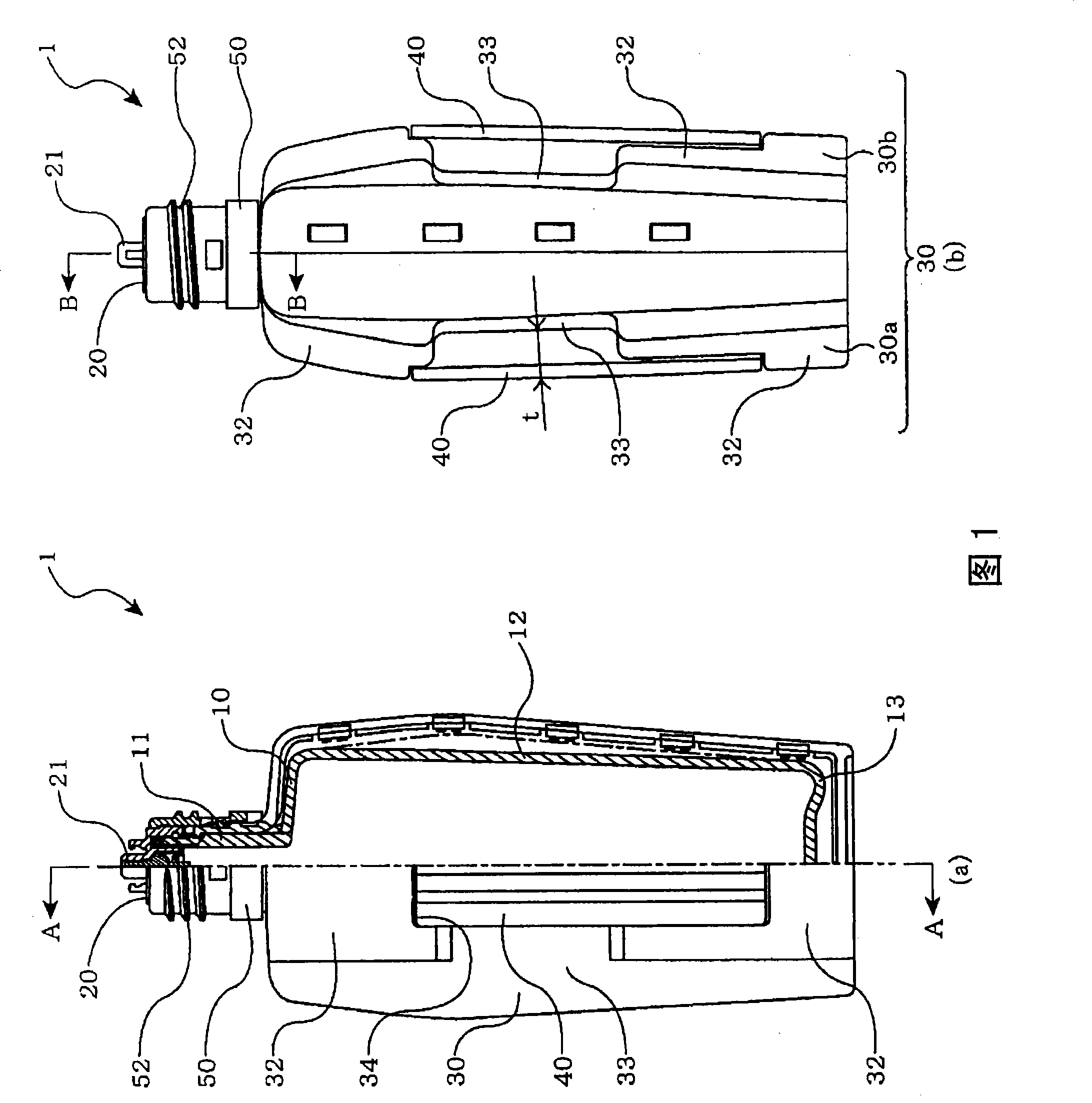

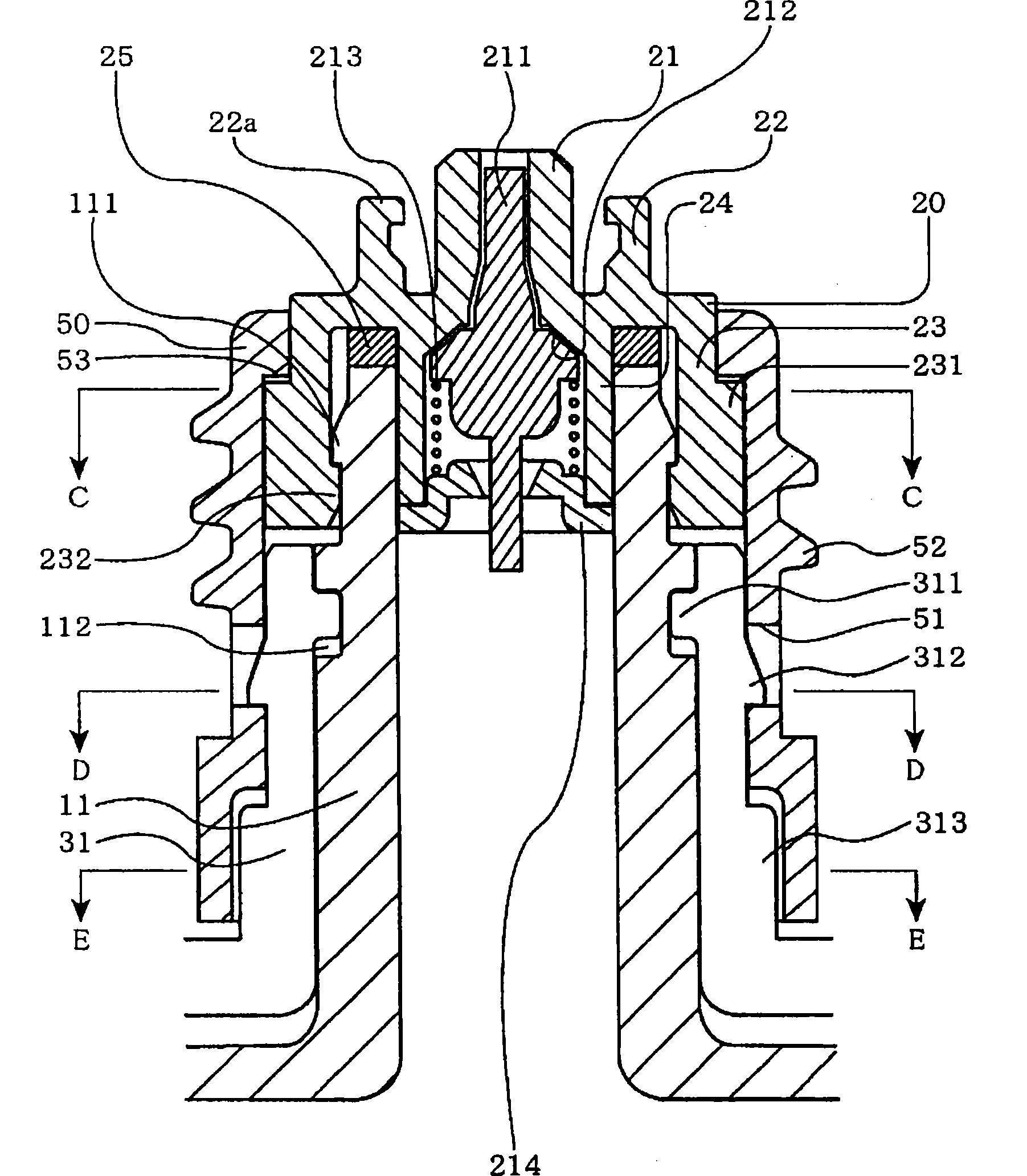

[0089] here, figure 1 (a) is a partial notch front view showing the outline of this embodiment, figure 1 (b) is a schematic side view of this embodiment. in addition, figure 2 yes figure 1 (b) B-B section view.

[0090] The refueling container 1 of the present embodiment includes a container body 10 having a nozzle portion 11 , a body portion 12 , and a bottom portion 13 .

[0091] In the present embodiment, the container main body 10 is made to reduce its volume, inject fuel such as methanol filled inside in a predetermined amount into the fuel storage part of the fuel cell, and then recover the volume while inhaling the atmosphere gas in the fuel storage part, and pass These actions are cycled for continuous fuel injection operations.

[0092] Such a container main body 10 can be obtained as follows, from high-density polyethylene (HDPE), low-density polyethylen...

no. 2 example

[0147] Next, a second embodiment of the refueling container of the present invention will be described.

[0148] in addition, Figure 16 It is a cross-sectional view of main parts showing the outline of this embodiment, and it is different from that of the above-mentioned first embodiment. figure 1 (b) B-B sectional view is equivalent. This embodiment is defined as a modified example of the first embodiment described above.

[0149]In the above-mentioned first embodiment, the coupling 20 is formed so as to be fitted with the nozzle part 11, however, it is not limited to the direct attachment device of the coupling 20 to the nozzle part 11. In this embodiment, if Figure 16 As shown, the coupling 20 is screwed to the outer peripheral surface of the nozzle part 11 while inserting the opening end edge of the nozzle part 11 between the outer peripheral cylindrical part 23 and the inner peripheral cylindrical part 241 formed in the coupling 20 .

[0150] In this case, when the...

no. 3 approach

[0154] Next, a third embodiment of the refueling container of the present invention will be described.

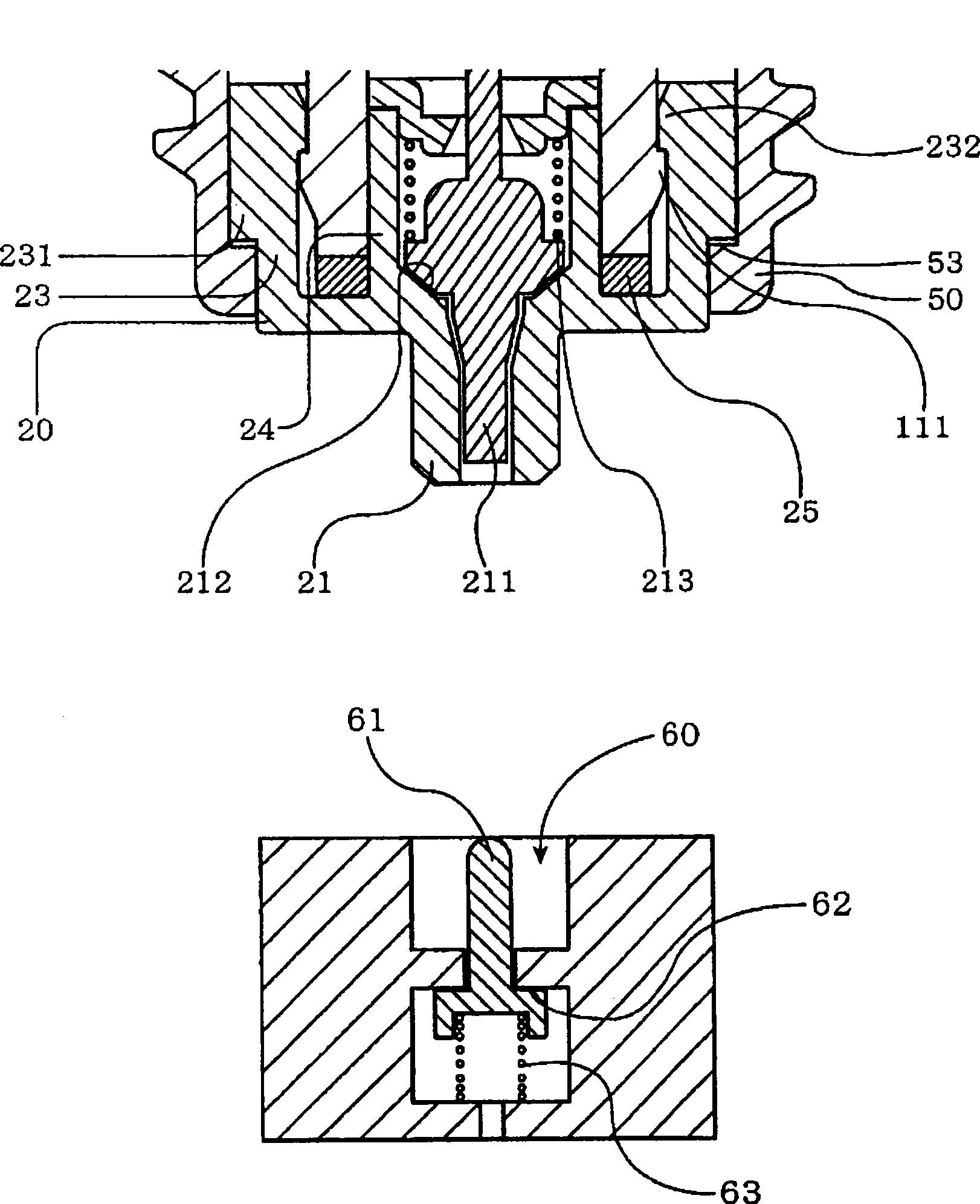

[0155] here, Figure 17 (a) is a partial notch front view showing the outline of this embodiment, Figure 17 (b) is a schematic side view of this embodiment. Figure 18 yes Figure 17 (b) L-L section view. This embodiment is defined as a modified example of the first embodiment described above.

[0156] in addition, Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 Respectively with those representing the first embodiment image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 9 Correspondingly, the drawing of this embodiment is shown. In addition, the same code|symbol is attached|subjected to a common structure as needed, and the description of 1st Embodiment is quoted, and it is the same also in 4th and 5th Embodiment mentioned later.

[0157] In the present embodiment, the coupler 20 has a cylindrical portion 241 communicating with the fuel inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com