Rice bucket for making crispy-rice laying device

A technology of spreading rice crusts and rice hoppers, which is applied in the field of rice hoppers, and can solve problems such as difficulty in controlling the amount of rice in stainless steel trays and difficulty in ensuring the quality of rice crusts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

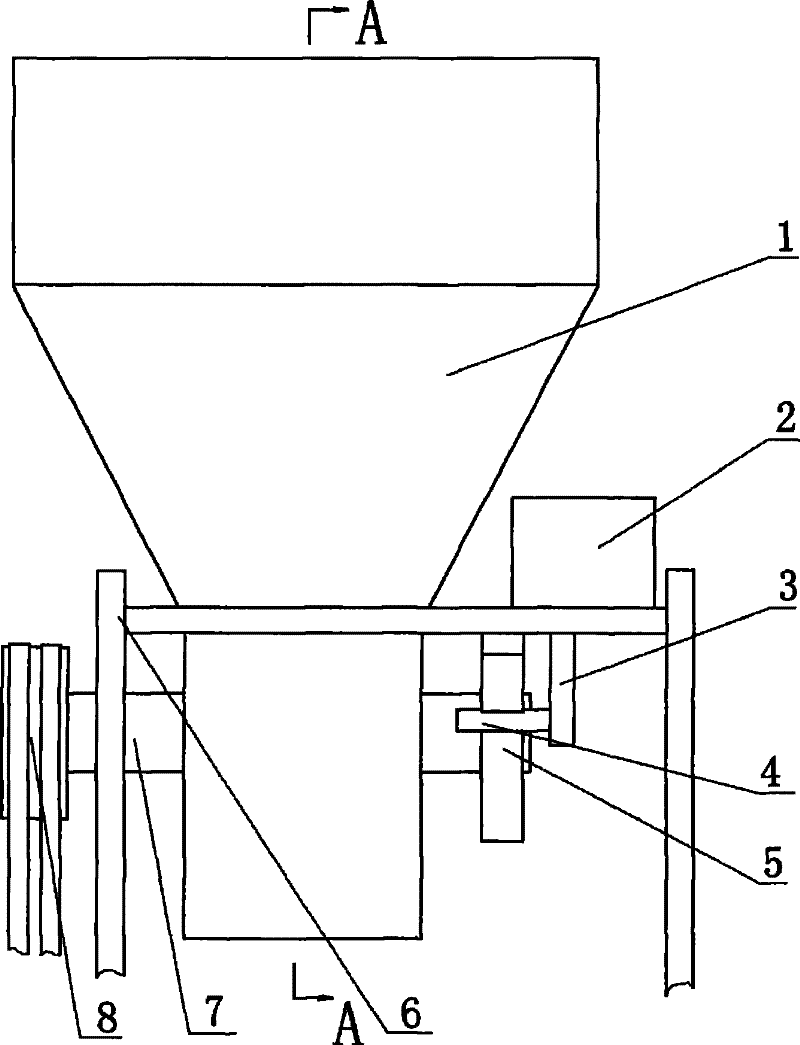

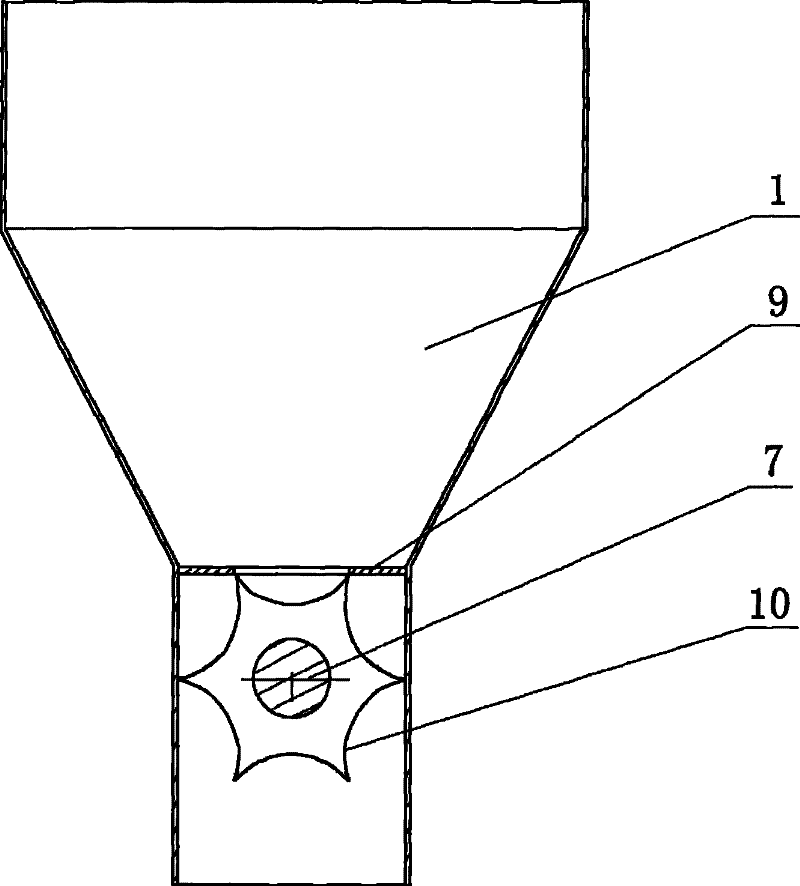

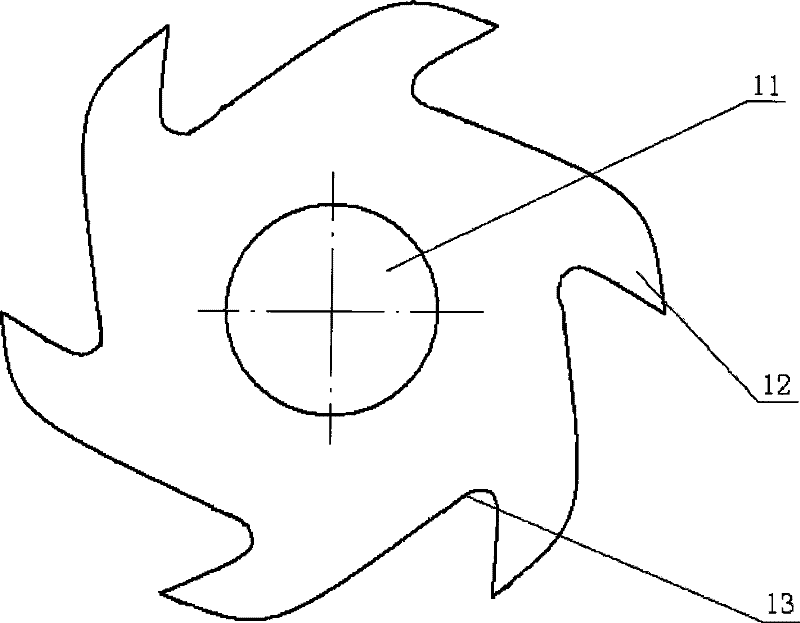

[0015] like figure 1 , figure 2 , image 3 As shown, a rice hopper device for making crispy rice spreading equipment includes a rice hopper 1, a timing control mechanism 2, a connecting rod 3, a stop roller 4, an index wheel 5, a frame 6, a mandrel 7, a partition 9, Rotate the rice container 10 and the pulley 8, the dividing plate 9 in the rice bucket has an opening, the opening just below the dividing plate 9 has a rotating rice container 10, the rotating rice container 10 is made of stainless steel, and the rotating rice container 10 has Six rice-holding grooves evenly distributed on the concentric circles, the chord length of each rice-holding groove is consistent with the opening width of the dividing plate 9, and the maximum outer circle of the rotating rice-holding device 10 and the spacing of the dividing plate are 1 to 3 millimeters. The rice container 10 is fixedly connected with the mandrel 7, and the end of the mandrel 7 stretching out from the rice bucket 1 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com