Combustion-engine fixed blade ring exterior-ring sheave-groove processing feeler-block

A technology for processing stator blade rings and grooves, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large variation in profile size, high processing difficulty, large outer ring groove size, etc., and achieves guaranteed Processing accuracy and quality, saving processing time, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

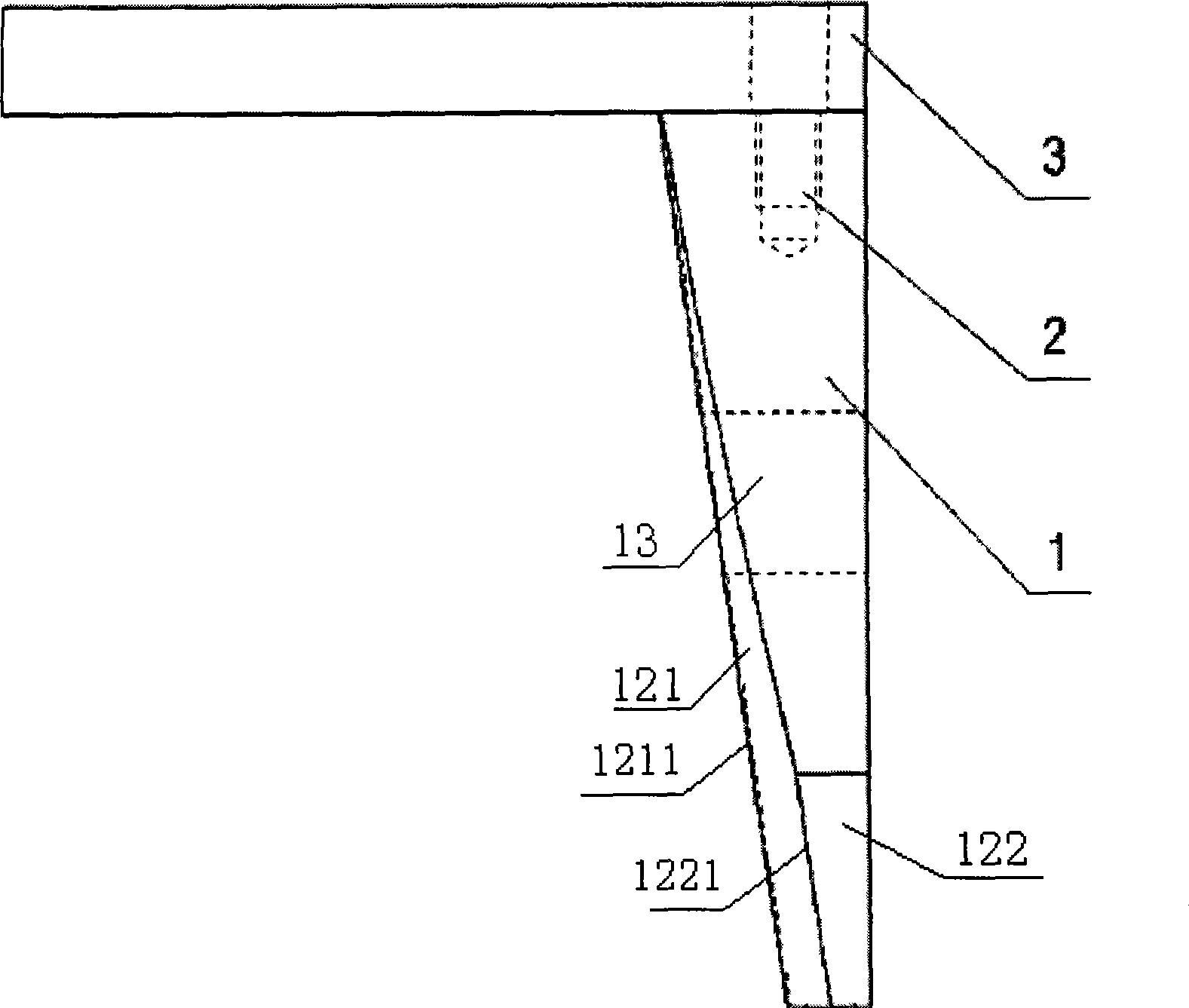

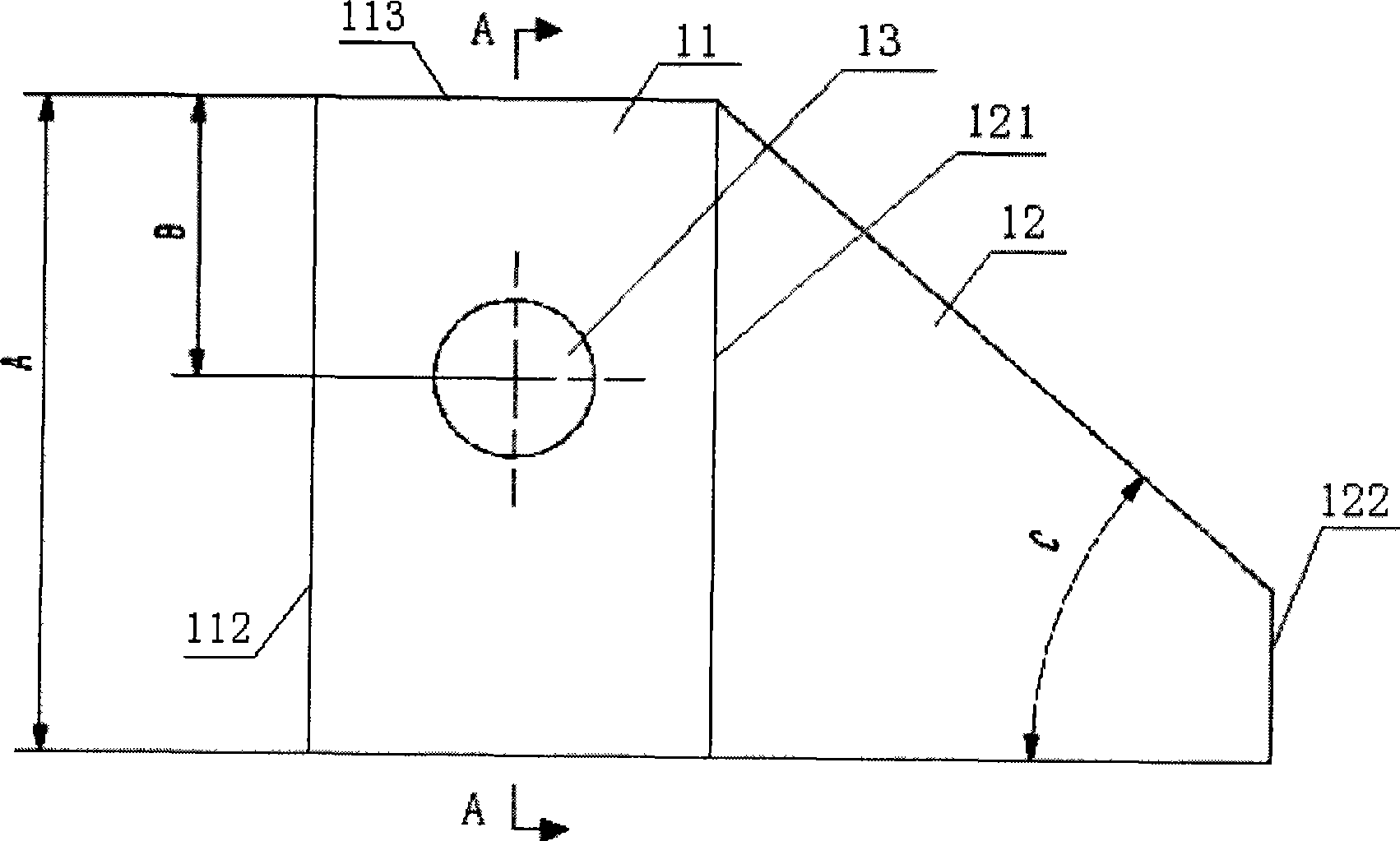

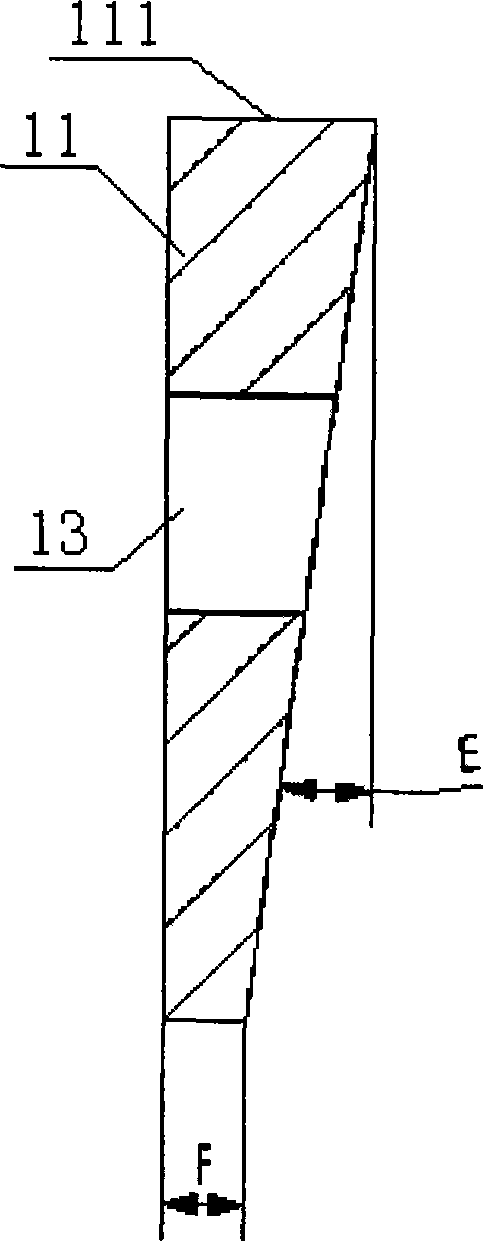

[0027] see Figure 1 to Figure 5 , the figure shows a gas turbine vane ring outer ring groove processing tool setting block of the present invention, which is used in the wheel groove processing of the gas turbine stator blade ring outer ring 4, including a reference block 1 and a passing screw 2 The plate 3 vertically fixed on the reference block 1, the orthographic projection of this reference block is a pentagon, and one of the surfaces is a conical surface, and the rest of the surfaces are planes, which includes a rectangular shape with a conical surface in the orthographic projection Part 11 and another part 12 integrated with it in orthographic projection having the shape of a right-angled trapezoid with the same conical surface, wherein:

[0028] A round hole 13 is pierced on the conical surface of the rectangular portion 11 of the reference block, and the thickest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com