Rolling/drawing type laminated opening wire coating machine

A wire wrapping machine, rolling and drawing technology, applied in coating, arc welding equipment, metal material coating process, etc., can solve problems such as unsatisfactory, poor powder coating ability, uneven powder coating, etc. The filling rate is adjustable and the powder feeding uniformity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

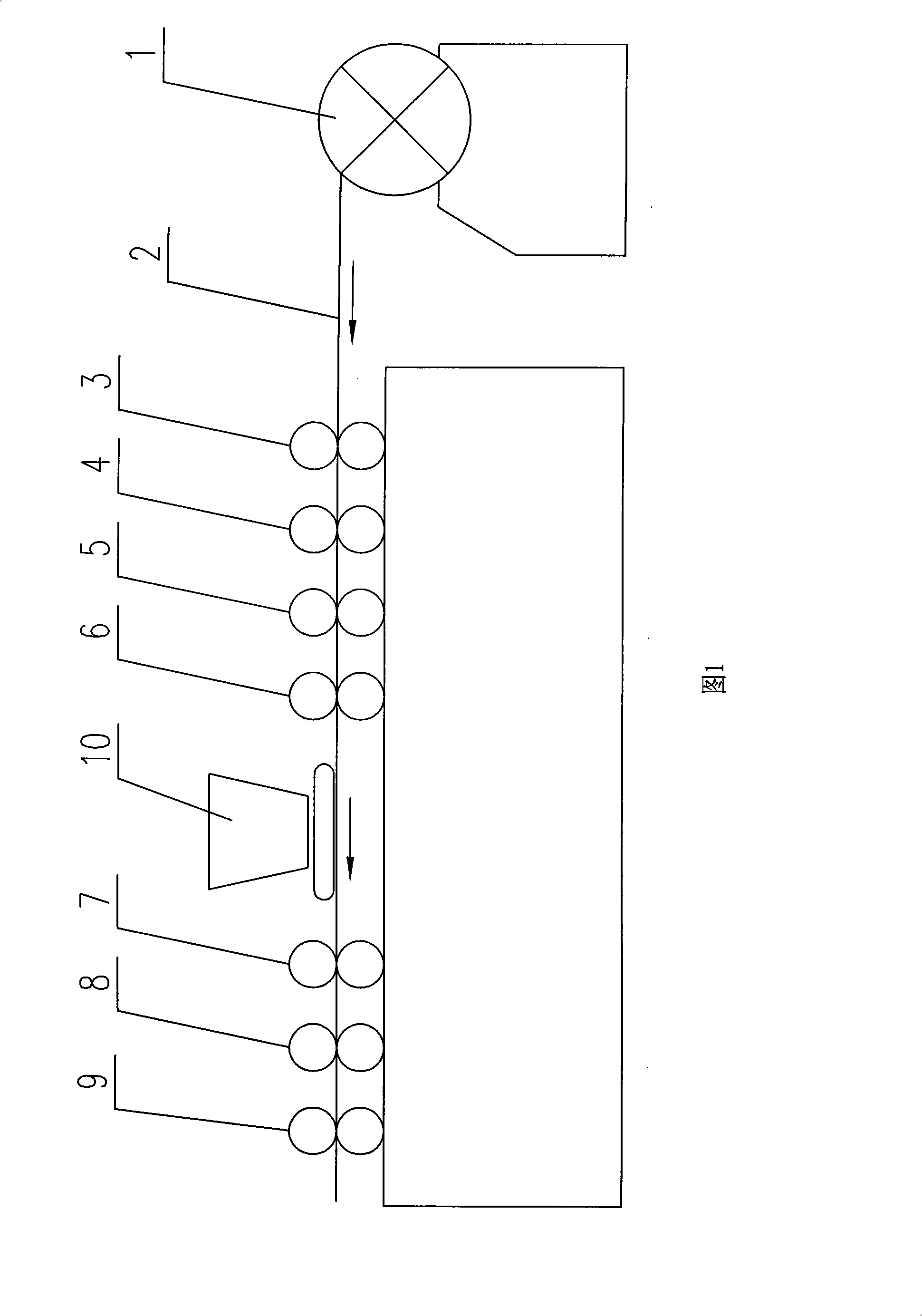

[0015] Such as figure 1 As shown, the present embodiment comprises a damping type unwinding mechanism 1, a rolling device, a powder feeder 10, and a closing device, wherein:

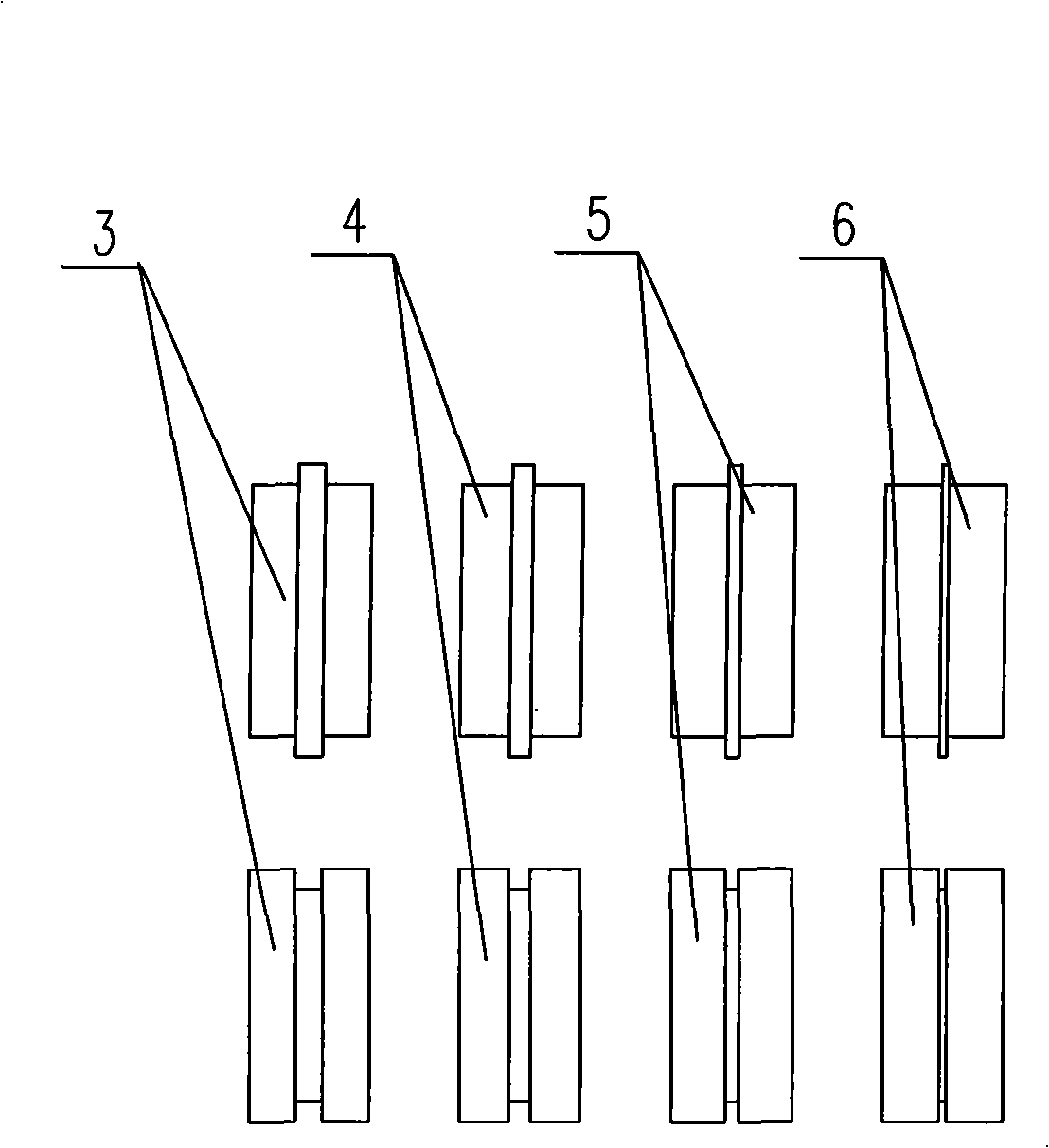

[0016] Such as figure 2 As shown, the rolling device is composed of positioning wheel 3, pre-rolling wheel 4, forming rolling wheel 5 and shaping rolling wheel 6, positioning wheel 3, pre-rolling wheel 4, forming rolling wheel 5 and shaping rolling wheel 6. The upper cam and the lower concave wheel are engaged respectively, and the width of the engagement gradually decreases from the positioning wheel, the pre-rolling wheel, the forming rolling wheel and the shaping rolling wheel in turn;

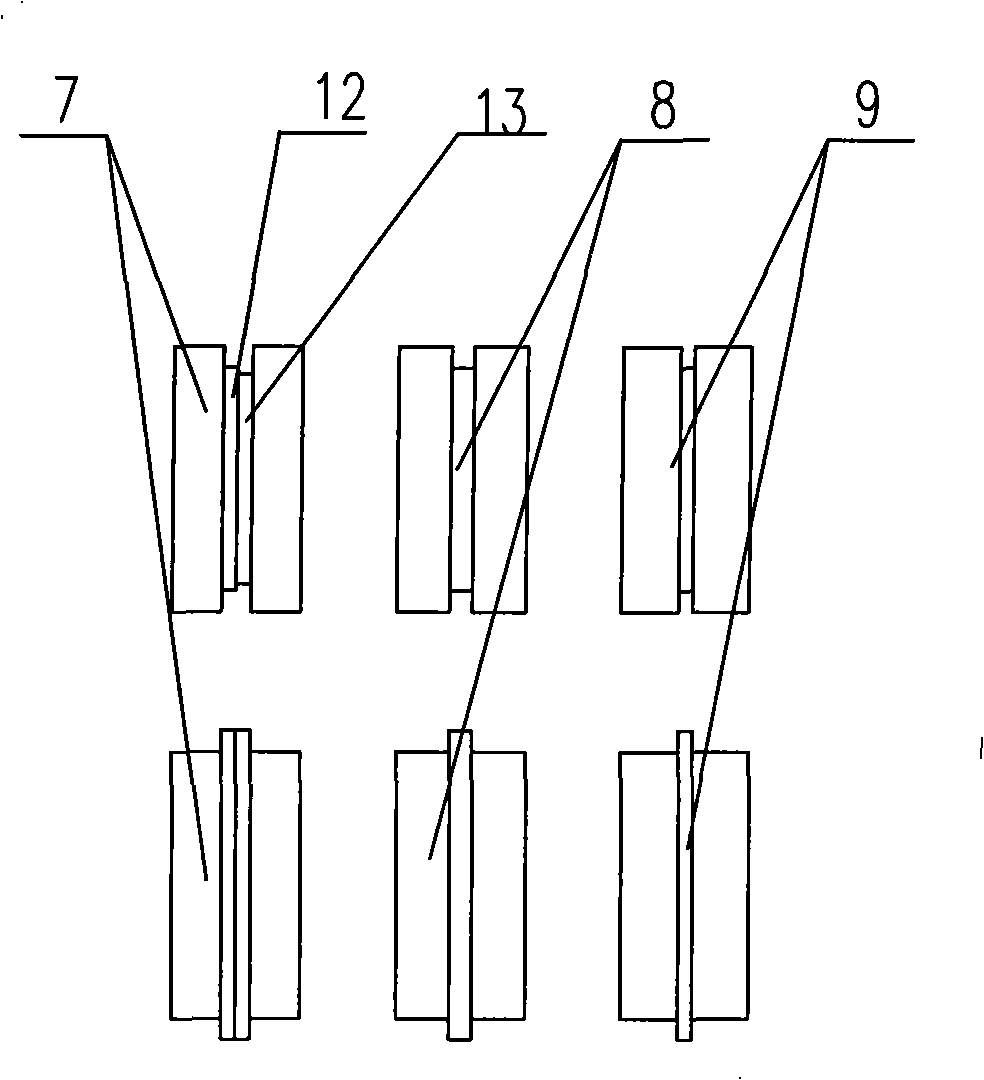

[0017] Such as Figure 4 As shown, the powder feeder 10 is located between the rolling device and the closing device, and it is composed of a powder feed funnel 15 and a conveyor belt 14. The length of the powder outlet of the powder feed funnel is slightly smaller than the width of the conveyor belt and evenly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com